Dyeing machine

A dyeing machine and dyeing vat technology, which is applied in the field of dyeing machines, can solve the problems of fabrics being easily knotted, folded together, affecting the quality of fabric dyeing, and uneven dyeing, so as to reduce the number of repeated dyeing, avoid knotting and folding, and improve dyeing efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

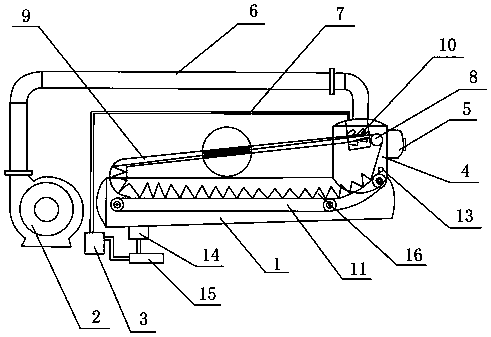

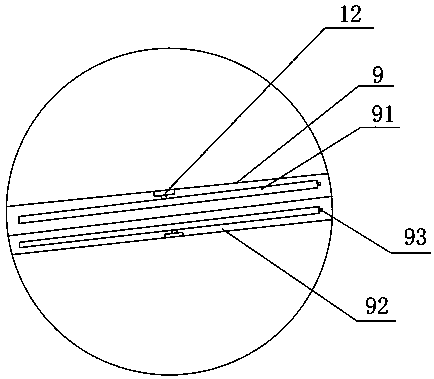

[0015] A kind of dyeing machine of the present invention, as Figure 1-2 As shown, it includes a dye vat 1 with an internal space for dyeing operations, a blower 2, and a dye vat 3. One end of the dye vat 1 is vertically provided with an extension 4, and the side of the extension 4 is provided with a sealing door 5. The sealing After the door 5 is opened, it is used for taking out and putting in the fabric. The blower 2 is provided with an air duct 6, the dye solution tank 3 is provided with a dye solution tube 7, and one side of the extension part 4 is provided with a fabric guide roller 8 for guiding The fabric to be dyed passes through the preset position, and the side corresponding to the extension part 4 and the cloth guide roller 8 is provided with a cloth guide pipe 9. Nozzles 10 are provided, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com