Automatic fabric opening device

A technology of fabric and bellows, which is applied in the direction of untwisting devices for processing textile materials, etc., and can solve the problems of low efficiency of fabric opening by hand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution described in the application of the present invention will be described in a non-limiting manner below in conjunction with the accompanying drawings and embodiments.

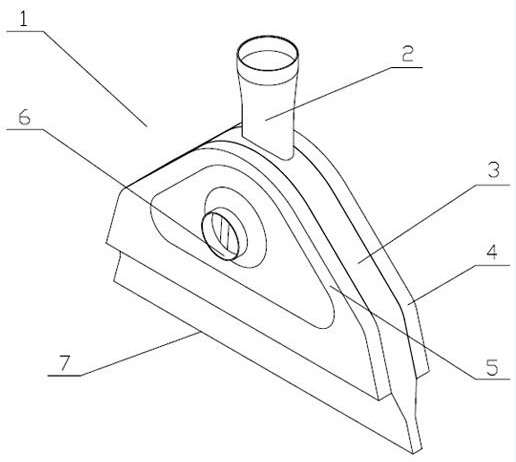

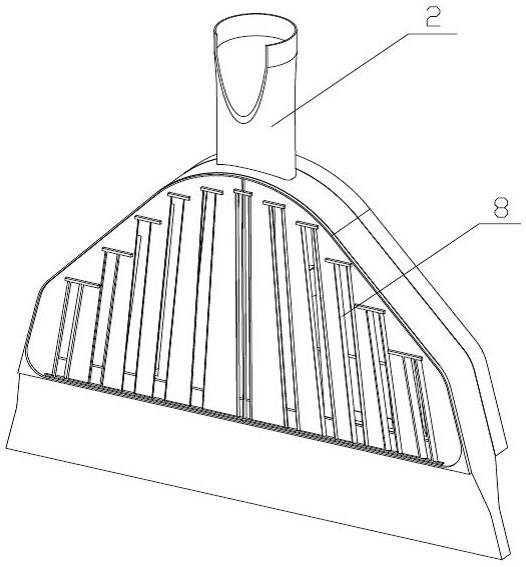

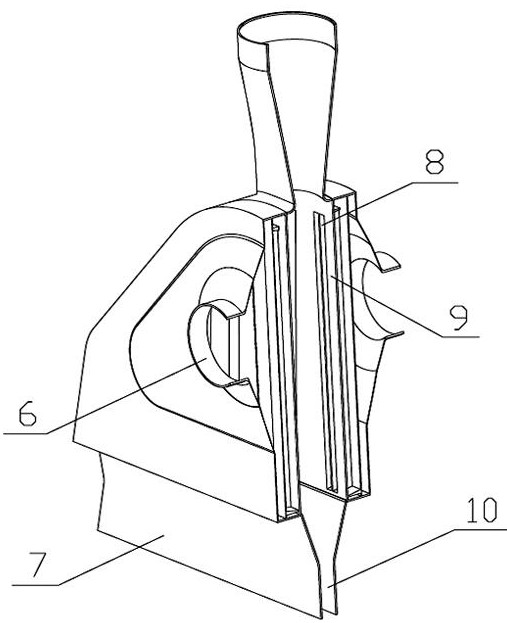

[0015] Such as figure 1 As shown, the automatic fabric stretching device 1 described in the application of the present invention is a triangular bellows. The purpose of its structural setting is to gradually expand the width of the internal space of the device, so that the incoming fabric can gradually have enough tension when it moves downward. open space. The middle part of the bellows is the central bellows 3, and the head end of the fabric enters from the fabric inlet 2 above the central bellows 3, and the fabric inlet 2 gradually transitions from the circular shape of the entrance to a relatively flat ellipse. into an open state, and the entry speed of the fabric can be controlled by the drag force of the nozzle of the dyeing machine. The front and rear of the central bellows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com