Dyeing device with long and flat nozzle and automatic filter system and unwinding control method of dyeing device

A technology of automatic filtration and dyeing device, applied in the direction of processing textile material untwisting device, processing textile material equipment configuration, spraying/jetting textile material processing, etc. The effect of good color uniformity, preventing fabric damage and improving dyeing machine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

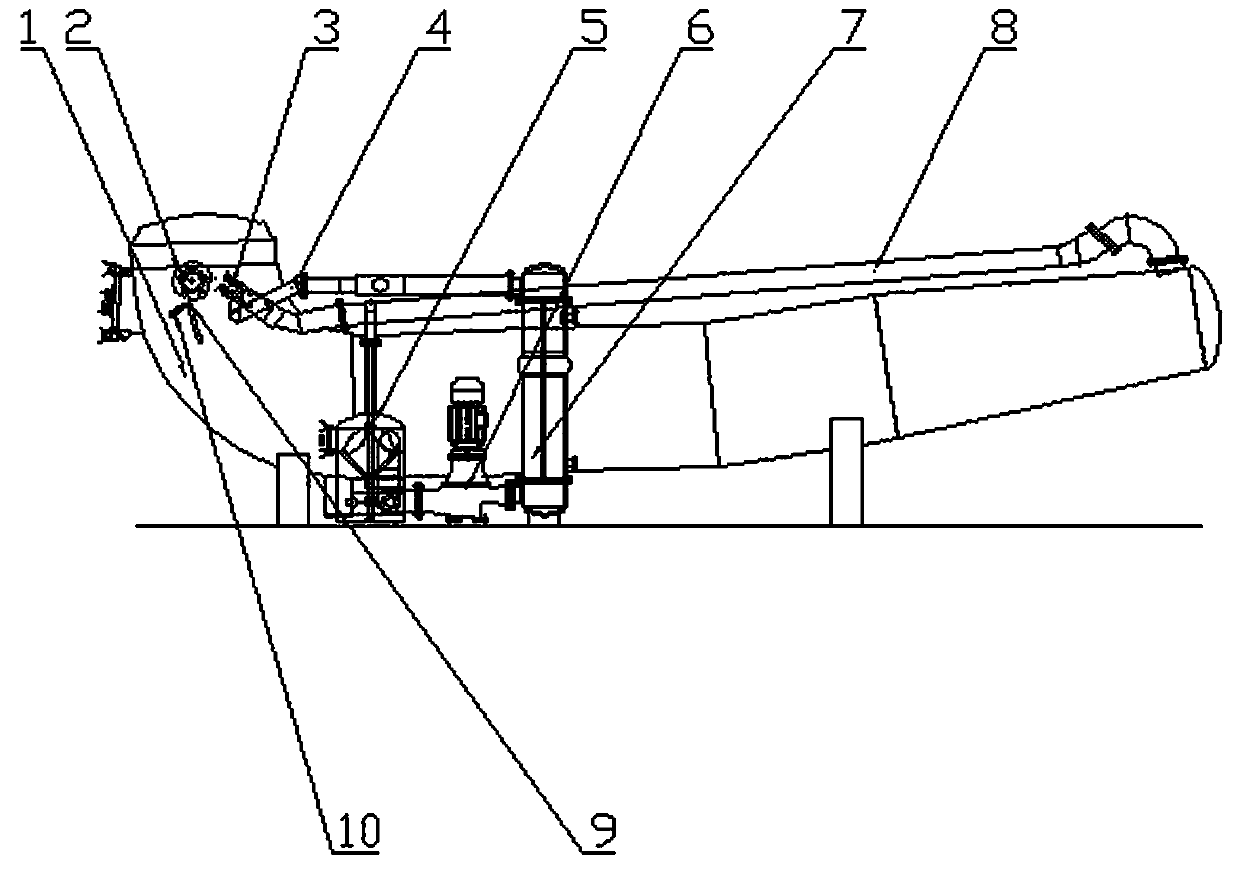

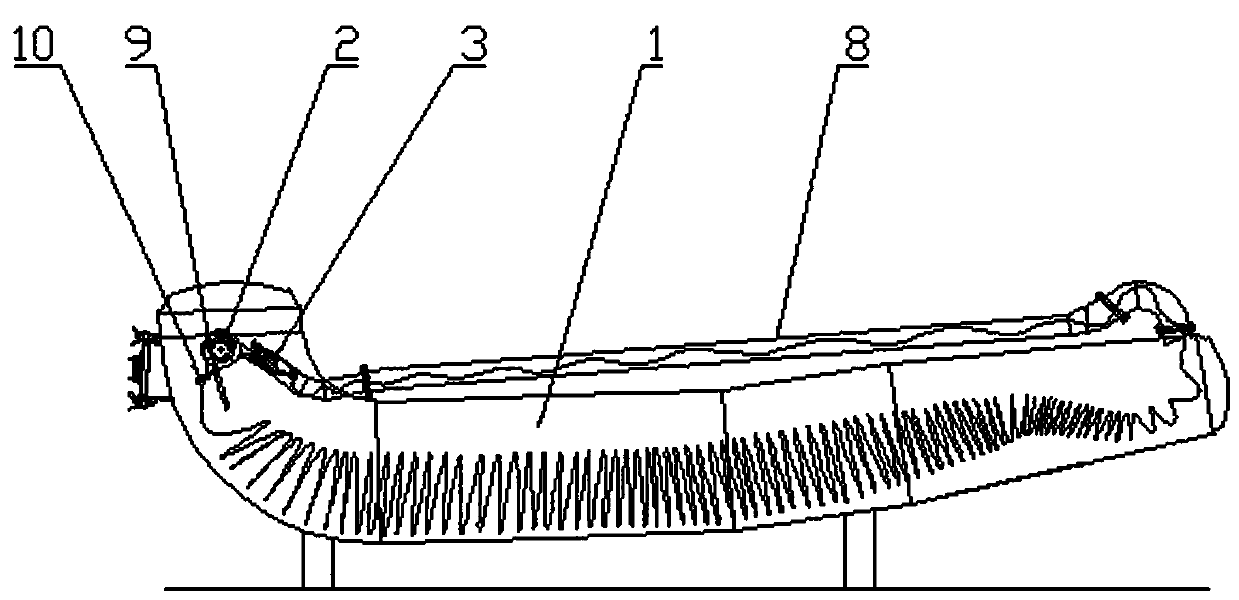

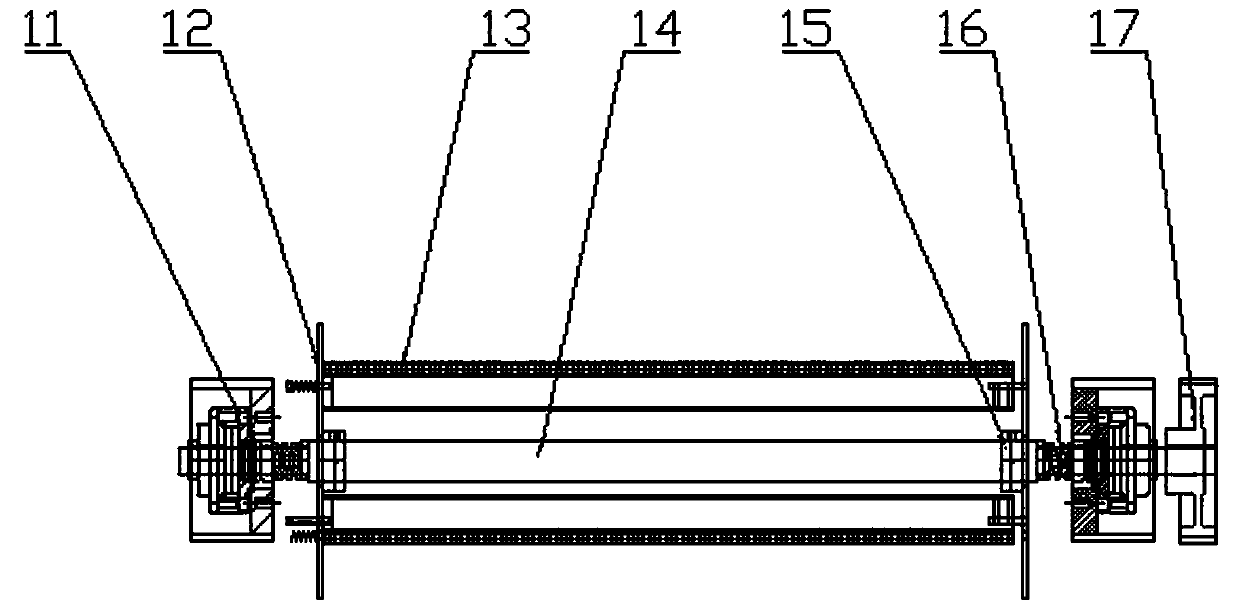

[0033] Example: such as Figure 1-7 As shown, a dyeing device with an automatic filtering system includes a dyeing vat 1, the dyeing vat 1 is provided with a cloth guide wheel turning conversion surface assembly 2 fixed to the inner wall of the dyeing vat 1, and the cloth guide wheel turning conversion surface assembly 2 There is an overflow cloth guide pipe 8 connected with the pipeline of the dyeing tank 1 on the side, and the overflow cloth guide pipe 8 is integrated with the overflow cloth guide pipe 8 between the cloth guide wheel turning surface assembly 2 The slapping jet printing and dyeing assembly 3 connected by the pipeline, the dye liquor filter 5 connected with the dyeing vat 1 by the pipeline is arranged on the side of the dyeing vat 1, and the dye liquor filter 5 and the slapping jet printing and dyeing assembly 3 are provided with The dye solution feed pipe 4 communicated with the 3-phase pipeline of the beating jet printing and dyeing assembly. The slapping j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com