A kind of cotton fiber dyeing device and its dyeing method

A dyeing device and dyeing method technology, applied in the field of textile dyeing, can solve the problems of inability to carry out continuous dyeing, affecting the final effect of cotton fiber dyeing, and obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Preparation of laps

[0067] Raw cotton fiber is prepared into cotton rolls with uniform thickness through picking cotton-matching cotton-cleaning-rolling.

[0068] (2) Dyeing

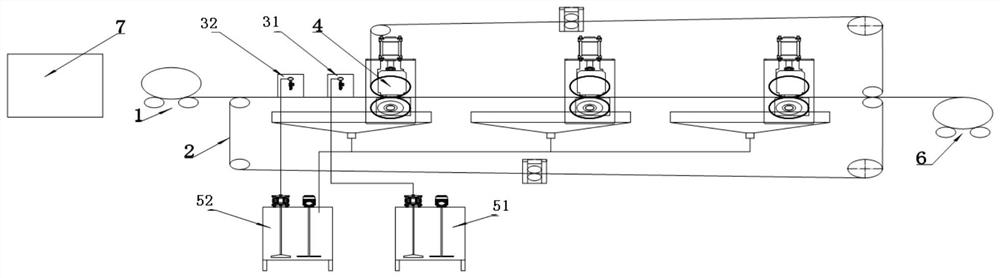

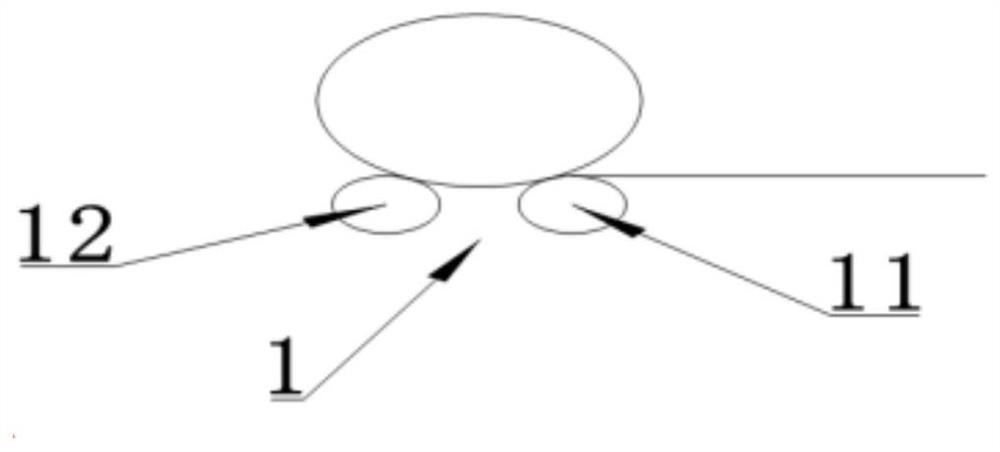

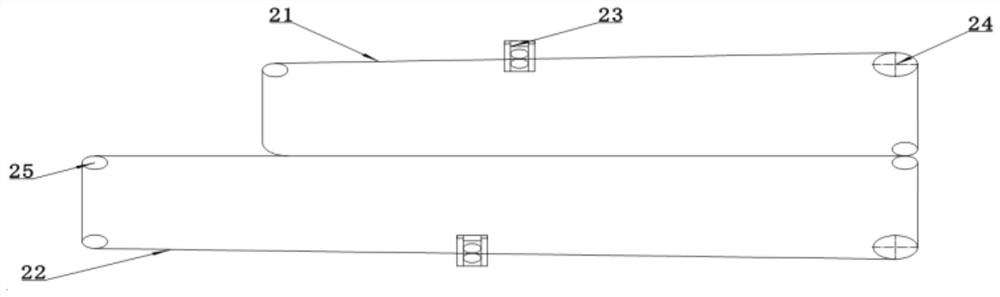

[0069] use figure 1 In the dyeing device shown, the cotton roll is placed on the unwinding unit 1, and is unwound into a cotton layer (thickness is 20mm, 430g / m 2 ), the cotton layer is conveyed horizontally on the endless mesh belt unit 2. Among them, the closed-loop guide belt is a 60-mesh polyester screen. The circulating mesh belt unit 2 is in contact with the rollers for cyclic operation, and at the same time, the mesh belt deviation correction device, mesh belt tensioning device and guide roller follow the upper and lower circulating mesh belts for synchronous operation.

[0070] Carry out spray dyeing during conveying process, newly equipped dye liquor spray equipment 31 sprays newly prepared dye liquor, the spray speed is 800g / min, reuse dye liquor spray equipment 32 sprays back ...

Embodiment 2

[0084] (1) Preparation of Articles and Volumes

[0085] The raw cotton fibers are blown-carded-pre-drawn-slivers and rolled to prepare slivers with uniform thickness and rolled.

[0086] (2) Dyeing

[0087] use figure 1 In the dyeing device shown, the cotton sliver is rolled up on the unwinding unit 1, and the cotton layer (thickness 8mm, 180g / m2) is formed through the unwinding unit. 2 ), the cotton layer is conveyed horizontally on the endless mesh belt unit 2. Among them, the closed-loop guide belt is 80 mesh nylon wire mesh. The circulating mesh belt unit 2 is in contact with the rollers for cyclic operation, and at the same time, the mesh belt deviation correction device, mesh belt tensioning device and guide roller follow the upper and lower circulating mesh belts for synchronous operation.

[0088] Spray dyeing during the conveying process, the newly equipped dye liquor spraying equipment 31 sprays the newly prepared dye liquor, the spraying speed is 600g / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com