Super cotton-like cashmere double-side fabric and production process thereof

A preparation process, double-sided fabric technology, applied in fabrics, dyeing methods, textiles, etc., can solve problems such as poor moisture transfer and quick drying, easy pilling, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

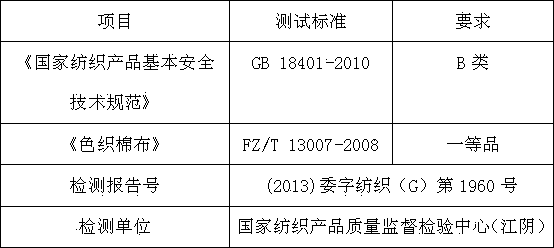

[0104] The present invention relates to a super imitation cotton cashmere double-sided fabric, the product specifications are as follows:

[0105] This product is [Supercool / cotton (80 / 20) 7.3tex×2]×[mercerized singeing yarn 18.2tex×2+cotton / cashmere (80 / 20)18.2tex] / 524(root / 10cm)×472(root / 10cm) / 145~147.5cm 1 / 3+3 / 1 double-sided twill yarn-dyed fabric. The warp tightness is 74%, the latitudinal frontal tightness is 53.2%, the latitudinal backside tightness is 37.6%, and the total tightness is 97.8%. The structure is stable.

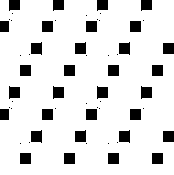

[0106] Special 1 / 3+3 / 1 twill double-sided yarn-dyed weave design (see figure 1 ), the warp is made of 7.3tex super-imitation cotton / cotton blended yarn, which is high-strength, high-absorbent and high-row, and can export sweat from the reverse side to ensure the comfort and structural stability of the entire fabric; the overall color of the fabric shows weft but not warp. The front (light color) is 18.2tex mercerized singeing yarn, twisted without knots...

Embodiment 2

[0108] A kind of preparation technology of super imitation cotton cashmere double-sided fabric, specifically as follows:

[0109] 1. Loose winding process

[0110] Adopt FADIS loosening machine and CROCHI winding machine. Warp speed 900m / min, package density 0.4~0.42g / cm 3 , weft speed 750m / min, package density 0.35~0.38g / cm 3 . Since the single fiber strength of Supercool fiber is 5.0~5.2CN / dtex, which is higher than 3.0~3.2CN / tex of general hydrophilic modified polyester, the original yarn contains 80% Supercool fiber, which has good strength, less broken ends and high production efficiency. The speed of the weft yarn is reduced, the density of the package is reduced, and the production is stable.

[0111] 2. Dyeing process

[0112] (1) Gray-green dyeing process of Supercool / cotton (80 / 20):

[0113] The dyeing process is always designed on the basis of not destroying the moisture-wicking and quick-drying properties of the original yarn. Silicone oil and wax are prohibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com