Dyeing machine with relaxation, untwisting and cockling devices

A technology of relaxing solution and dyeing machine, applied in the field of dyeing machine, can solve the problems of affecting the quality of the finished fabrics to be dyed, unable to produce wrinkles, poor dyeing effect, etc., saving labor and energy consumption, eliminating uneven shrinkage and shrinkage rate consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

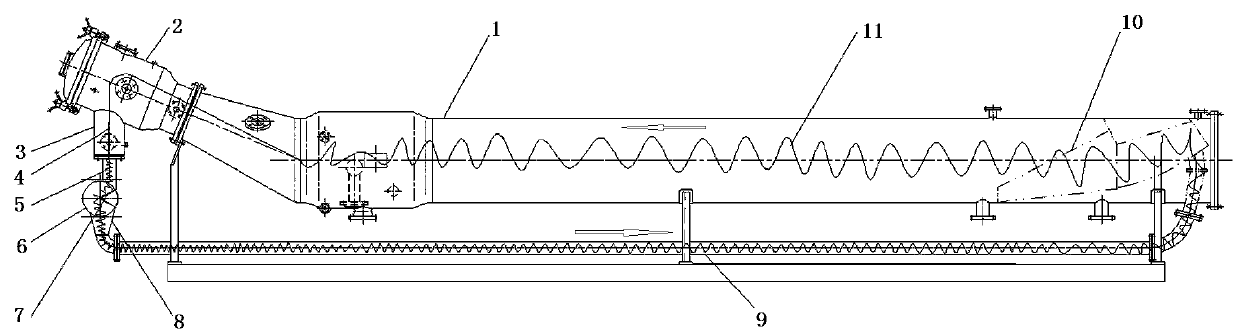

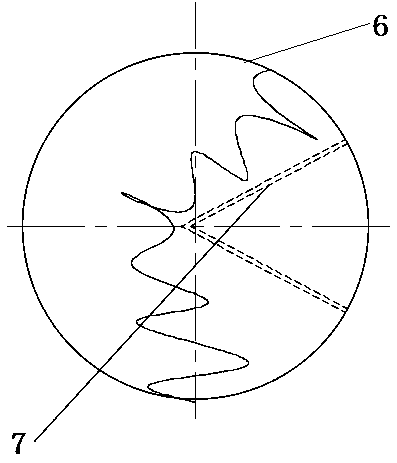

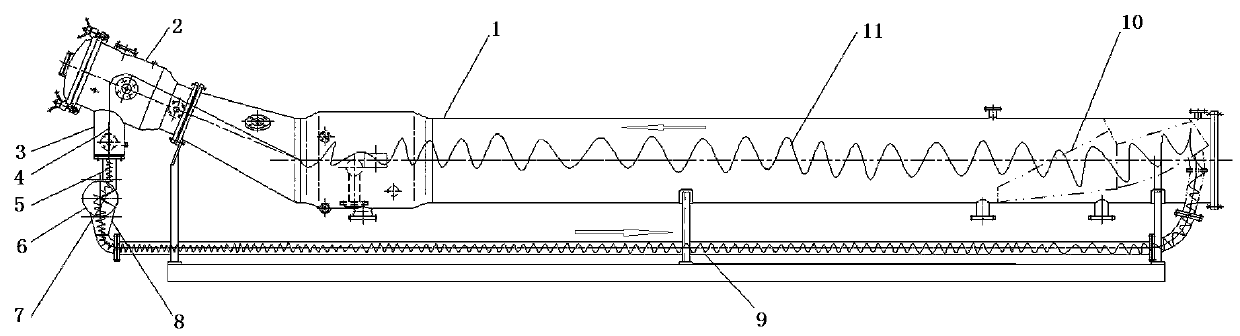

[0015] Example: as attached figure 1 As shown, a dyeing machine with a relaxation, untwisting and wrinkling device includes a main cylinder 1, a cloth guide cylinder 2, a nozzle chamber 3, a nozzle 4 and a cloth guide pipe 9, the nozzle is arranged in the nozzle chamber, and the nozzle chamber A loosening, untwisting and wrinkling device 6 is provided in communication with the cloth guide pipe. The loosening, untwisting and wrinkling device is a fabric guiding cavity, and a downwardly inclined impact baffle 7 is arranged laterally inside the cavity. The loosening, untwisting and wrinkling device The inlet end and the outlet end are respectively connected with a transition pipe and an inclined cone connecting pipe. The relaxation, untwisting and wrinkling device is installed and connected with the nozzle chamber and the cloth guide pipe respectively through the transition pipe 5 and the inclined cone connecting pipe 8. The taper connecting pipe and the cloth guiding pipe are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com