Cloth washing machine and washing method of cloth

A washing machine and cloth technology, which is applied to the processing of textile materials, the untwisting device for processing textile materials, the configuration of equipment for processing textile materials, etc., can solve the problems of long cleaning time, poor cleaning effect, and affecting the quality of cloth, and achieve removal Good, full cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

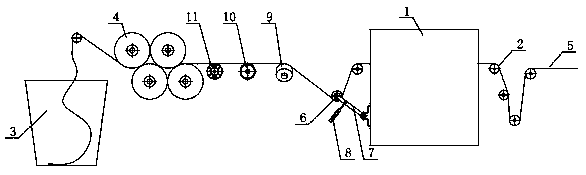

[0024] As shown in the drawings, a cloth washing machine in this embodiment includes a washing box 1 , a cloth conveying device 2 passing through the washing box 1 , and a material receiving bin 3 . A set of heated drying rollers 4 is also included. The preferred heating and drying roller 4 in this embodiment is a steam heating roller. The heating and drying roller 4 is arranged on the cloth conveying device 2 between the water washing box 1 and the receiving bin 3 . The axial direction of the heating and drying roller 4 is perpendicular to the moving direction of the cloth 5 . The conveying roller and the heating and drying roller 4 of the cloth conveying device form the structure that the cloth 5 is horizontally spread out and conveyed along the conveying roller and the heating and drying roller 4 . In this embodiment, two pairs of heating and drying rollers 4 are preferably provided to heat and dry the cloth 5 . In order to make the cloth 5 better cooperate with the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com