Mercerizing equipment

A kind of equipment, mercerizing technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, liquid/gas/steam removal with squeeze roller, etc., can solve the effect of mercerizing treatment on cloth, easy to be contaminated with wool and dust and other problems, to achieve the effect of cleaning and drying, improving cleanliness and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described with reference to the accompanying drawings.

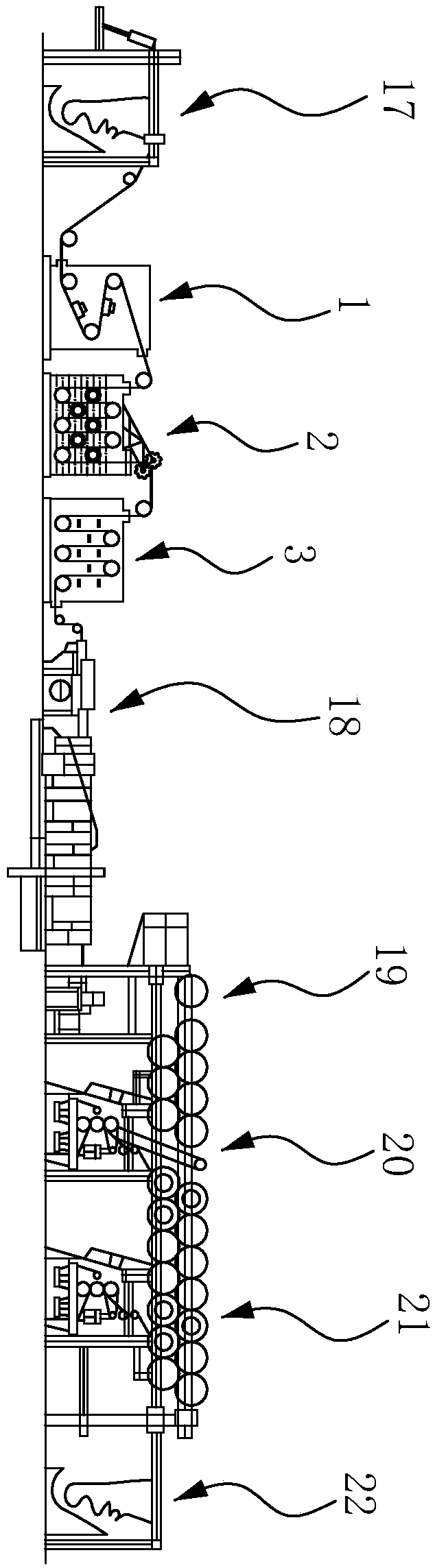

[0044] A mercerizing device such as figure 1 As shown, it includes a cloth doffing stand 17, a dust removal device 1, a cleaning device 2, a drying device 3, a mercerizing machine 18, a padding car 19, a stretching roller 20, a second padding car 21, and an unwinding roller arranged in sequence according to the cloth conveying direction. Cloth rack 22.

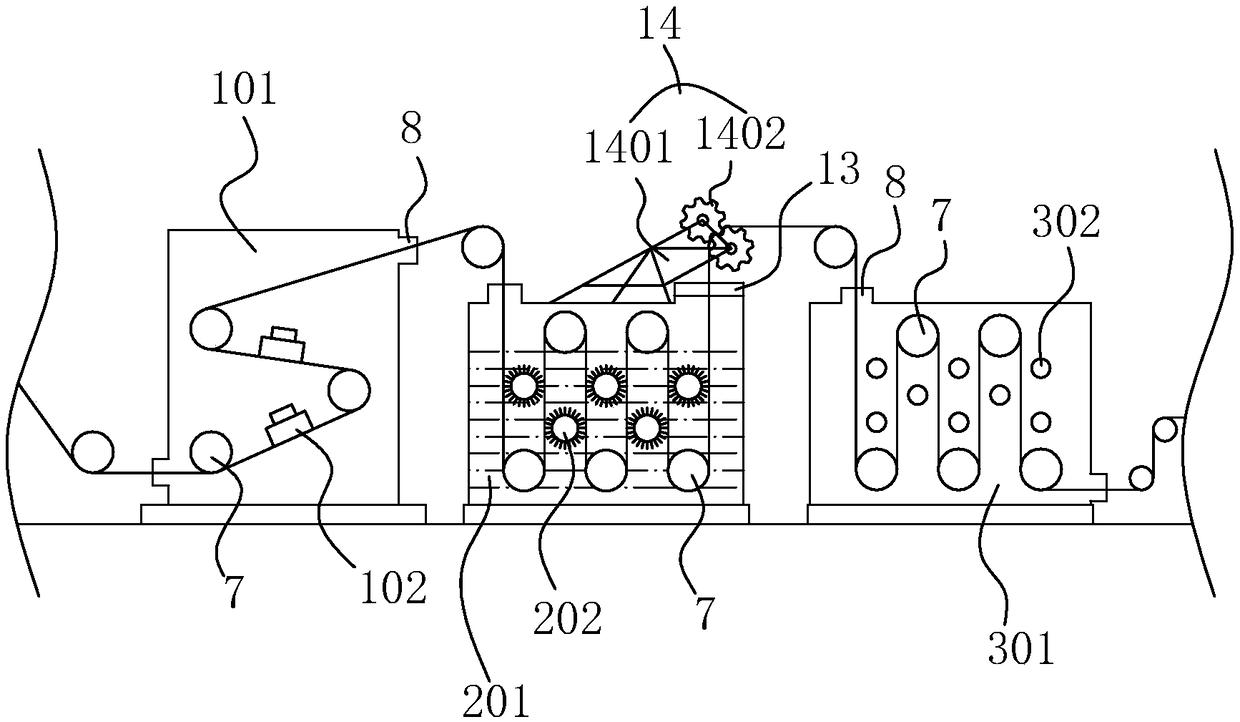

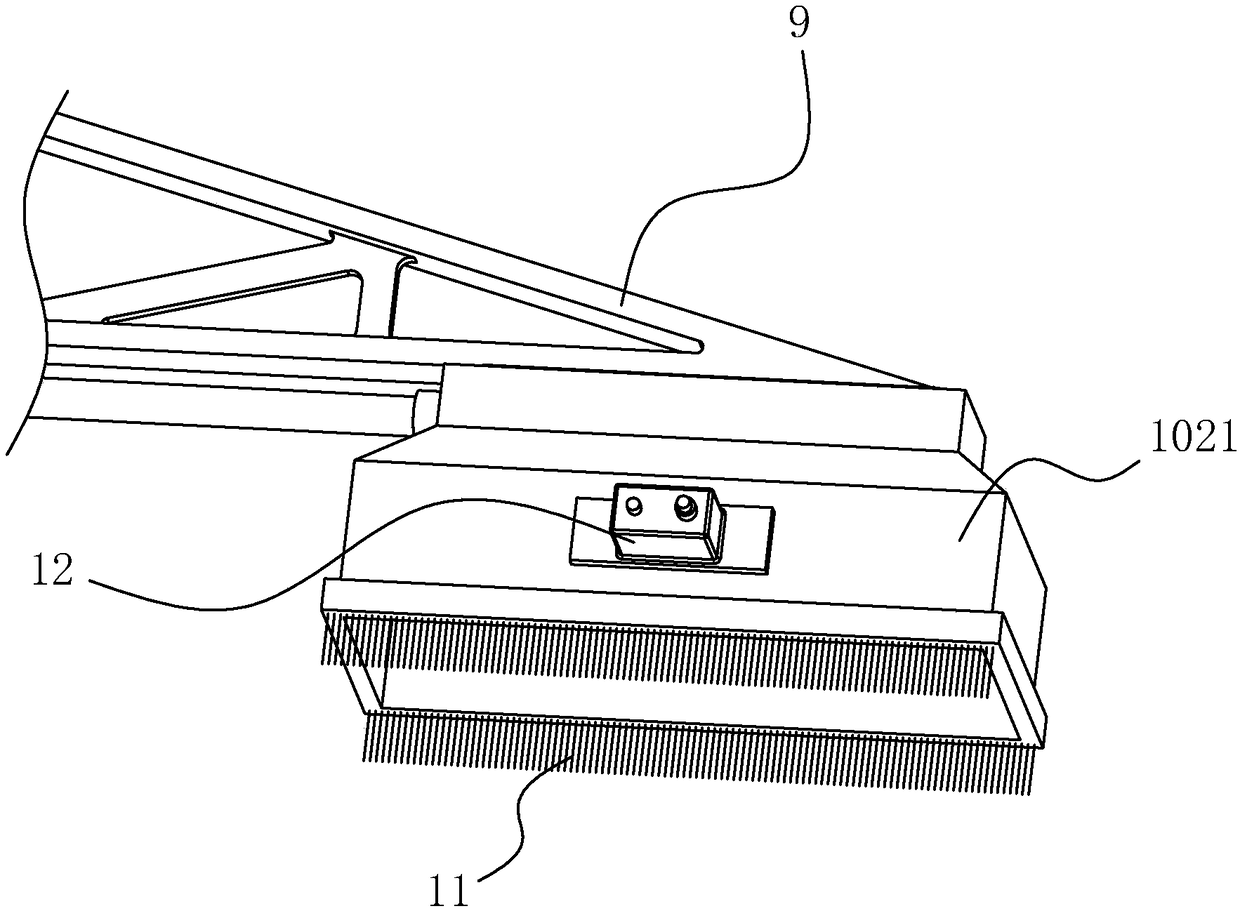

[0045] which, combined with figure 2 The dust removal device 1 comprises a dust removal box 101 and several dust collectors 102; the dust collector 102 is fixed on the inside of the dust removal case 101 and contacts with the cloth; in the dust removal case 101, several conveying rollers 7 for conveying the cloth are arranged, and the conveying roller 7 The two ends are rotatably connected to the wall of the dust removal box 101 and driven by a motor; the front and rear end faces of the dust removal box 101 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com