Textile dyeing and finishing integrated production system with high-frequency oscillation structure

A high-frequency oscillation, textile dyeing and finishing technology, applied in the direction of textile and papermaking, textile material treatment, textile material untwisting device, etc., to achieve uniform dyeing, good joint synchronization performance, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

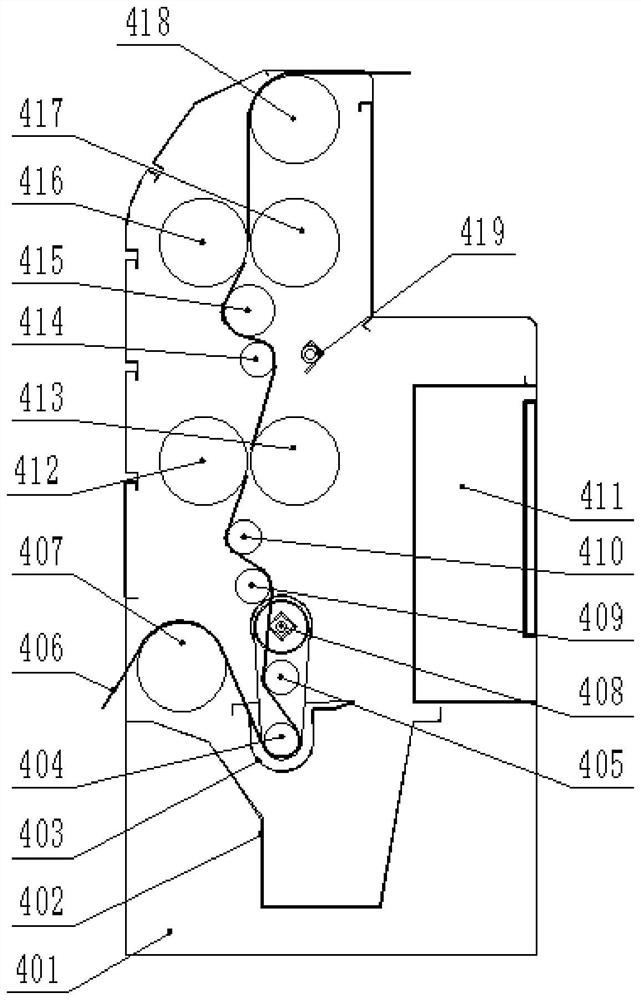

[0070] As shown in Figure 1, it is a schematic structural diagram of the pretreatment and dyeing system in the textile dyeing and finishing integrated production system with a high-frequency oscillation structure in Example 1 of the present invention; as shown in Figure 1-2, it is Example 1 of the present invention Schematic diagram of the finishing system in the textile dyeing and finishing integrated production system with a high-frequency oscillation structure; among them, 1 is the opening width unit, 2 is the degreasing and washing unit, 3 is the preheating and setting unit, and 4 is the forming film forming roll liquid device, 5 is the washing unit after dyeing, and 6 is the heat setting unit;

[0071] The textile dyeing and finishing integrated production system with high-frequency oscillation structure of the present invention includes a pretreatment and dyeing system and a finishing system; the pretreatment and dyeing system includes an opening unit 1, an oil removal an...

Embodiment 2

[0086] Others are the same as in Embodiment 1, the difference is that the opening width unit 1 is the opening width unit 1 is a 34-inch double-sided opening width machine, which adopts 36G needle fine gauge, multi-channel design, and is equipped with 6 tracks of upper, second, lower, and fourth , Up and down oil-immersed gear transmission design; stable appearance, beautiful appearance, firm structure, lower machine height, more in line with Asian operating habits; suitable for cotton, blended, polyester, nylon, acrylic and other weaving materials. The fabric is fine and dense, and the texture is clear, which is widely used in high-end clothing fabrics.

[0087] The 34-inch double-sided open-width machine adopts the German steel wire runway structure design, which reduces friction and reduces operating load, so that the equipment can achieve higher operating accuracy, smoother and more stable, and prolong the service life; the triangular runway design ensures the stable and eff...

Embodiment 3

[0089] Others are the same as in Embodiment 1, the difference is that the opening unit 1 is an untwisting and opening machine, which is mainly composed of untwisting, spreading, centering, cloth falling device and transmission mechanism, and is a building block structure; It adopts advanced technology such as microelectronics, so it has functions such as automatic untwisting, infrared centering, AC frequency conversion speed regulation, fabric draping and loosening, etc. Compared with imported and domestic similar machines, it is small in size, small in floor space, and moderate in height. It has the advantages of stable operation, balanced force, and convenient installation; it is widely used in rope scouring, bleaching and overflow dyeing of cotton, linen, wool, chemical fiber, silk and other fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com