Textile dyeing and finishing integrated production system with improved vacuum water absorption device

A vacuum water absorption, textile dyeing and finishing technology, applied in the field of textile fabric production, to achieve the effect of good joint synchronization performance, high degree of digitalization, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

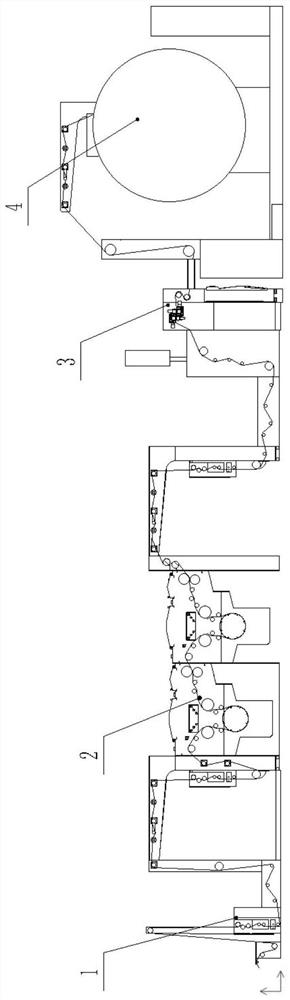

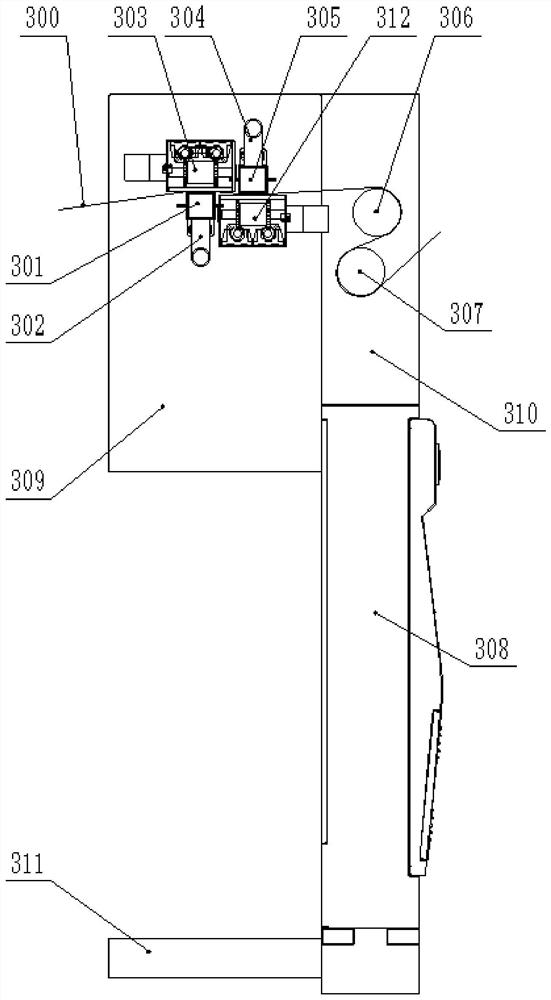

[0057]Such asPicture 1-1 As shown, a structural diagram of the pre-treatment and dyeing system in which the textile dyeing system of the present invention is improved to the vacuum absorbing device;Figure 1-2 As shown, a structural diagram of the post-finishing system in the textile dyeing integrated production system of the vacuum water absorption device is improved in the first embodiment of the present invention; wherein 1 is an open unit, 2 is an oil absorbing unit, 3 is a vacuum water absorbing device. 4 is a dyeing unit, 5 is the water washing unit, and 6 is a heat setting unit;

[0058]The textile dyeing integrated production system of the improved vacuum water absorption device of the present invention includes an open unit 1, an oil absorbing unit 2, a vacuum water absorbing device 3, a dyeing unit 4, a staining water washing unit 5, a heat setting unit 6; open unit 1 is connected to the oil absorbing unit 2; the oil absorbing unit 2 is connected to the vacuum water absorbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com