Textile dyeing and finishing integrated production system with edge cutting function

A technology of textile dyeing and finishing, production system, applied in textile and papermaking, cutting of textile materials, spray/jet textile material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

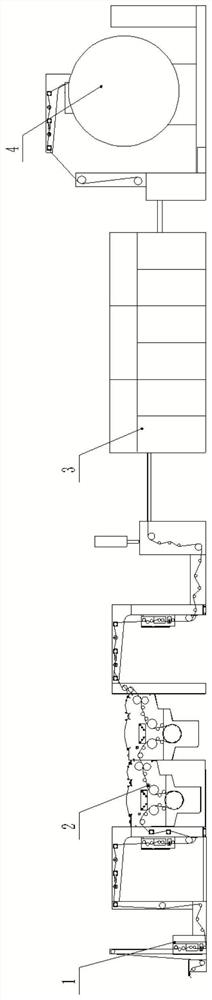

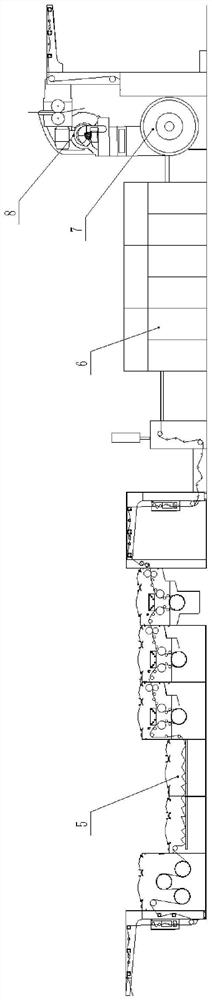

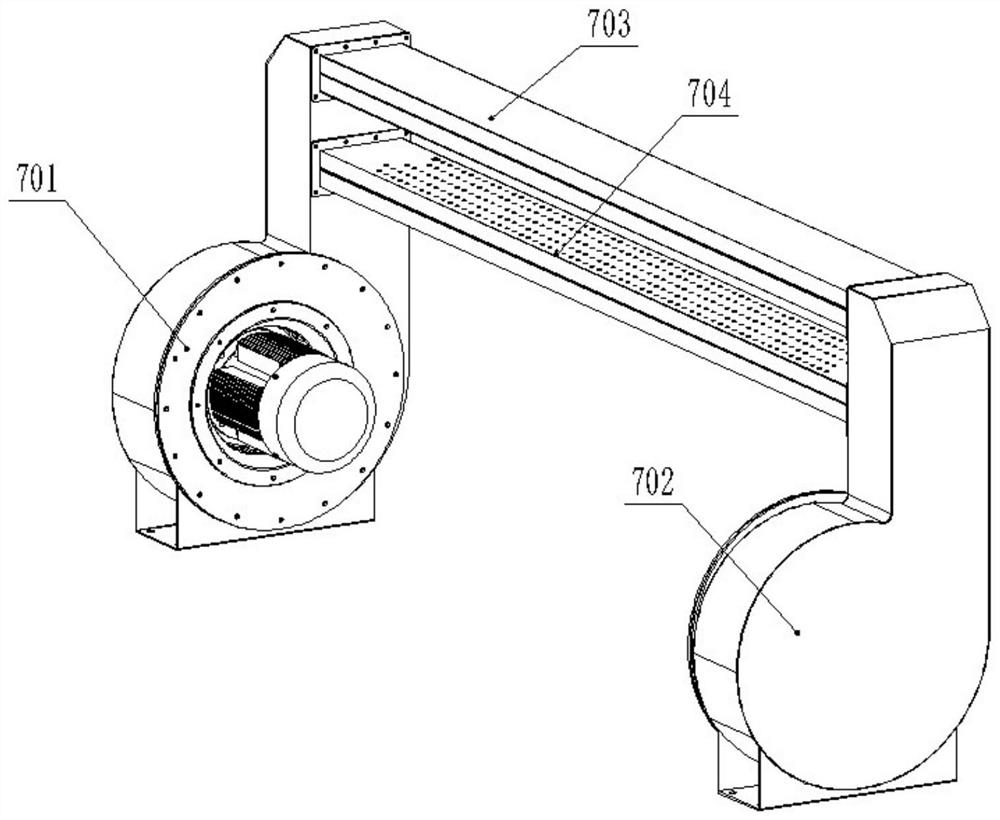

[0059] like Picture 1-1 As shown, it is a structural schematic diagram of the pretreatment and dyeing system in the textile dyeing and finishing integrated production system with trimming function in Example 1 of the present invention; such as Figure 1-2 As shown, it is a structural schematic diagram of the finishing system in the textile dyeing and finishing integrated production system with trimming function in Example 1 of the present invention; wherein, 1 is an opening unit, 2 is a degreasing and washing unit, and 3 is a preheating setting Unit, 4 is a dyeing unit, 5 is a washing unit after dyeing, 6 is a heat setting unit, 7 is a cold air system, and 8 is a trimming system;

[0060] The integrated production system of textile dyeing and finishing with trimming function of the present invention includes an opening unit 1, a degreasing water washing unit 2, a preheating setting unit 3, a dyeing unit 4, a water washing unit 5 after dyeing, a heat setting unit 6, and a trimm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com