Textile dyeing and finishing integrated production system with improved washing tank structure

A technology of textile dyeing and finishing and production system, which is applied in the field of textile fabric production to achieve the effects of energy saving, good joint synchronization performance and high degree of digitalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

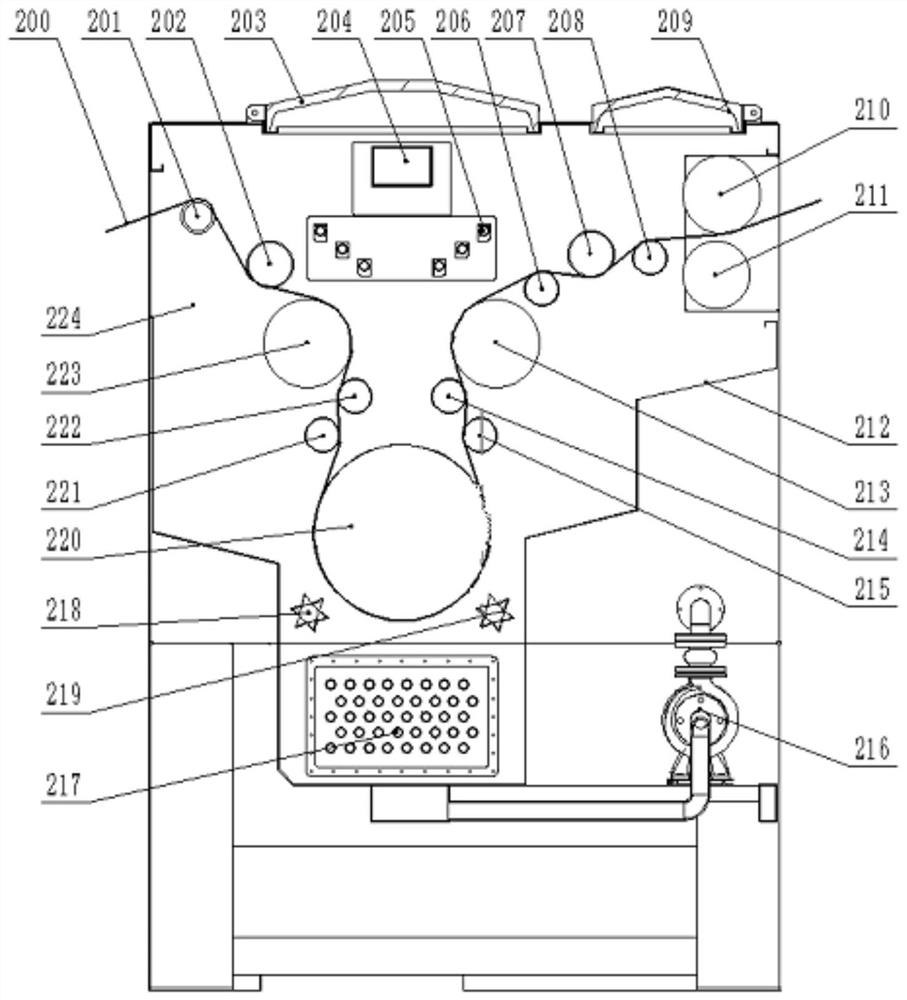

[0052] Such as Picture 1-1 As shown, it is a schematic structural view of the pretreatment and dyeing system in the textile dyeing and finishing integrated production system with improved washing box structure in Example 1 of the present invention; Figure 1-2 As shown, it is a schematic structural diagram of the finishing system in the textile dyeing and finishing integrated production system with improved washing box structure in Example 1 of the present invention; wherein, 1 is the opening unit, 2 is the washing box, and 3 is the preheating and setting unit , 4 is a dyeing unit, 5 is a washing unit after dyeing, and 6 is a heat setting unit;

[0053] The integrated textile dyeing and finishing production system with improved washing box structure of the present invention comprises an opening unit 1, a washing box 2, a preheating and setting unit 3, a dyeing unit 4, a washing unit after dyeing 5, and a heat setting unit 6; the opening unit 1 is connected with the washing bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com