Filament untwisting apparatus

A filament and untwisting technology is applied in the field of filament untwisting, which can solve the problems of inconvenient work and difficult realization, and achieve the effects of convenient operation, simple structure and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

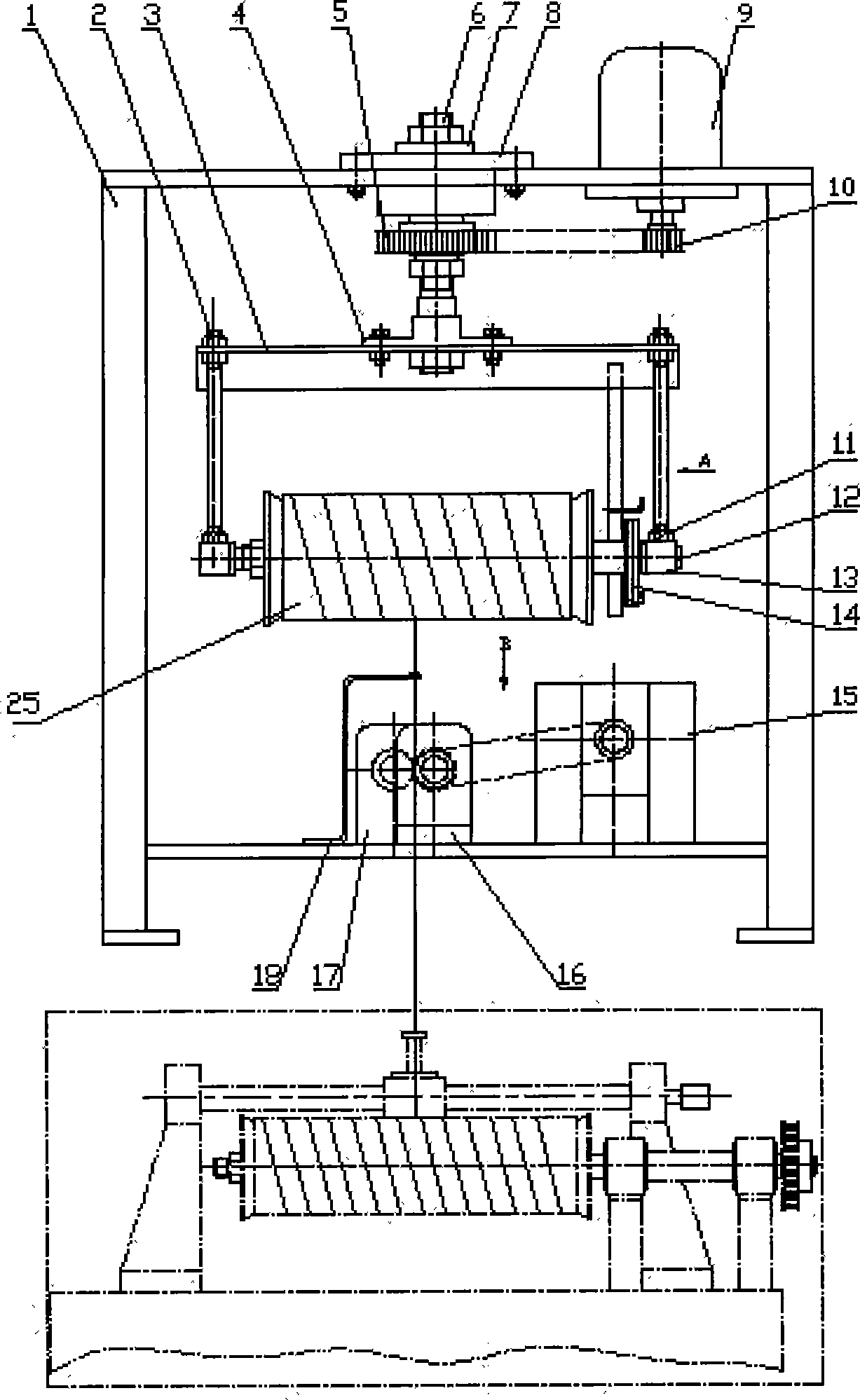

[0013] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

[0014] The general functional requirements of the mechanical device for filament untwisting of the present invention are: untwisting the filament packages that need to be untwisted, especially utilizing the natural twist (≤20 twists / meter) that is difficult to untwist by large-scale textile machinery, according to the degree of twist The value can adjust the speed of the two main motors to achieve the purpose of untwisting.

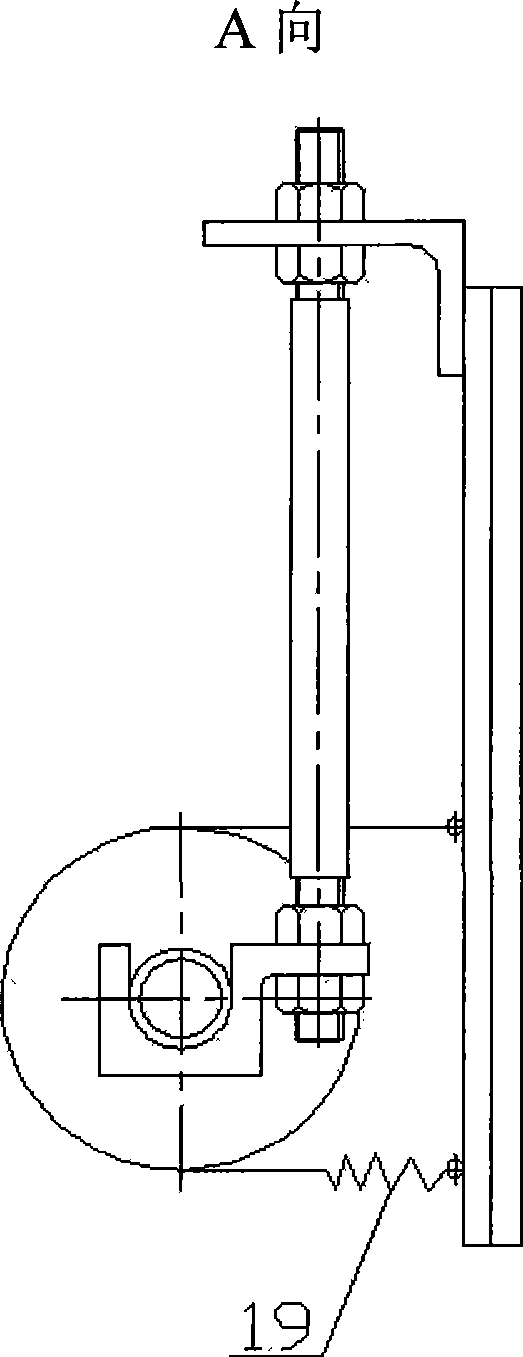

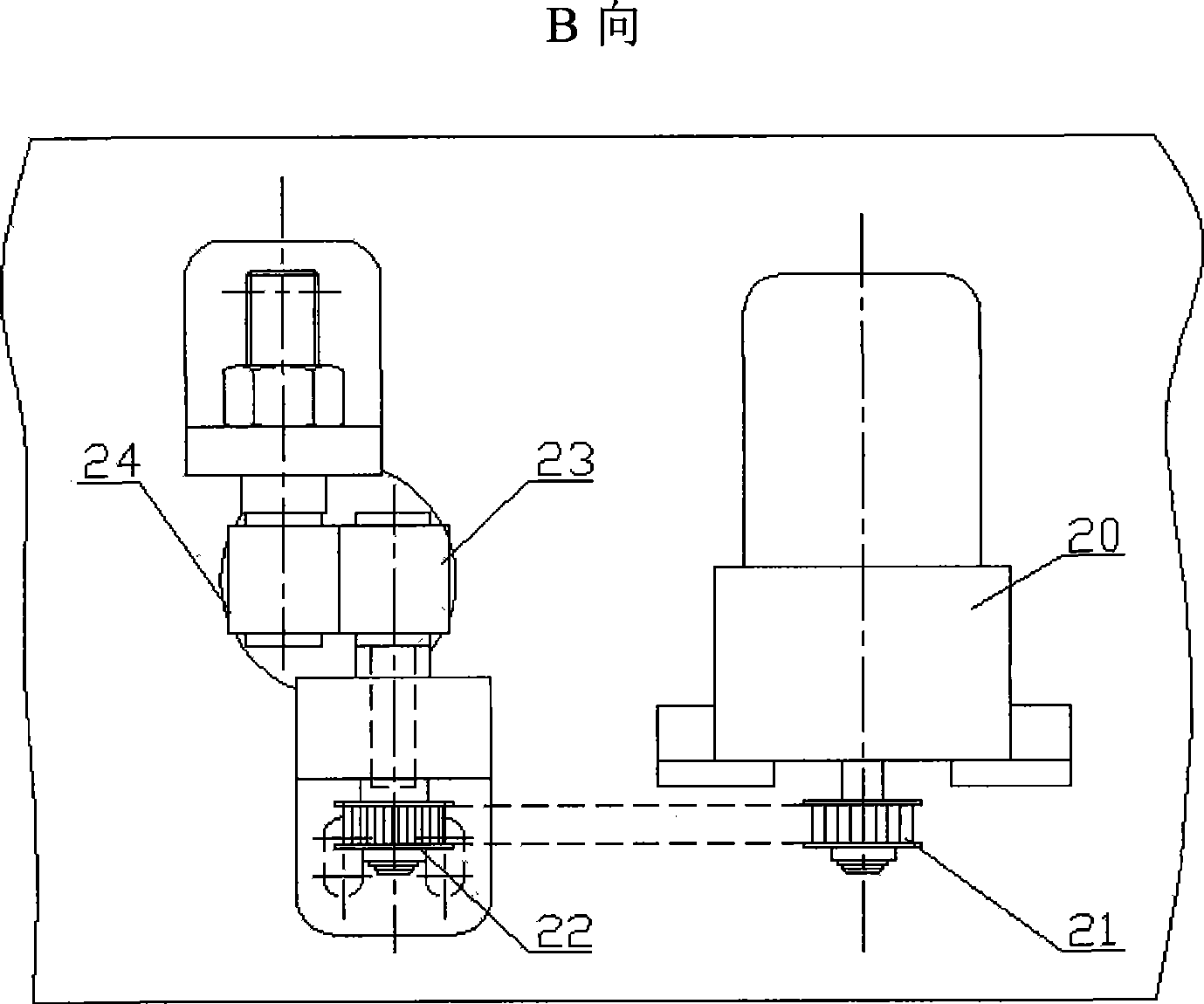

[0015] The mechanical device part of the present invention can generally be divided into a filament untwisting rotary mechanism, a filament unwinding rotary mechanism and a filament traction and length fixing mechanism. The transmission of the filament untwisting rotary mechanism is driven by the motor 9 to the synchronous pulley 10, which is transmitted to the synchronous pulley 5 through the synchronous belt. 8 is rotated by rolling be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com