Textile printing and dyeing machine for textiles

A technology for printing and dyeing machines and textiles, which is applied in the direction of textiles and papermaking, textile material processing, and textile material detwisting devices, etc. It can solve the problems of cotton cloth being wrinkled in the drum and uneven extrusion of cotton cloth, so as to avoid wrinkles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

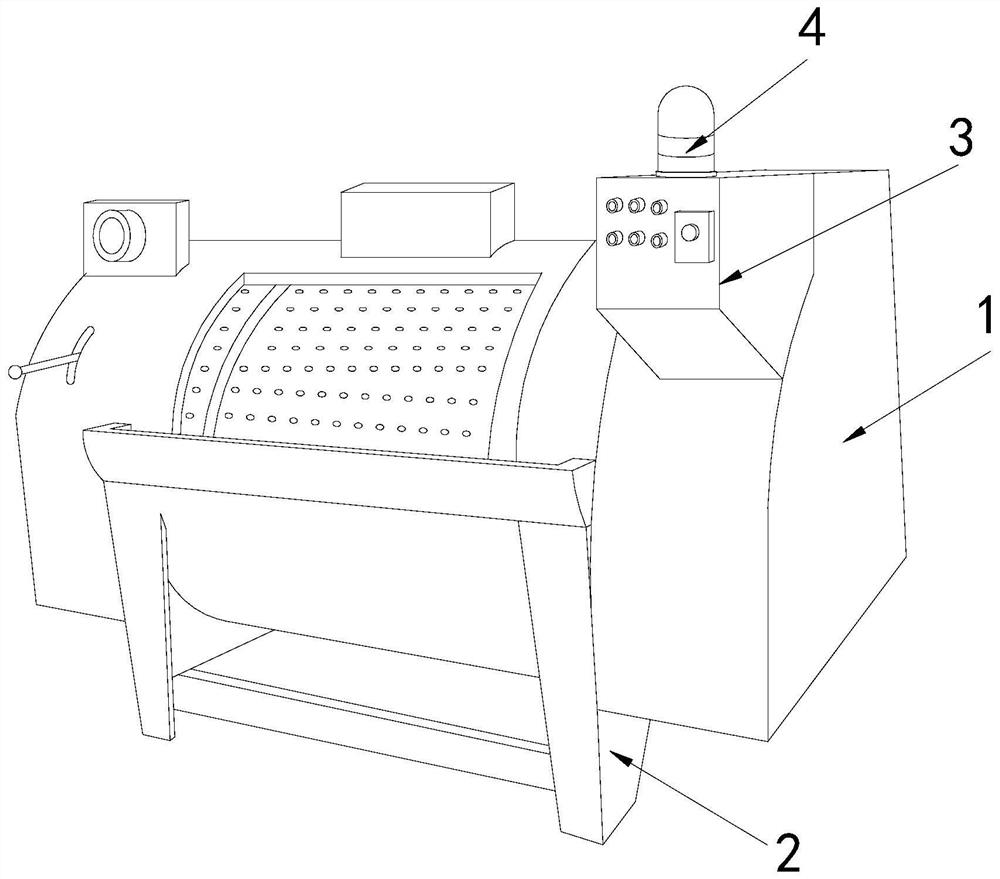

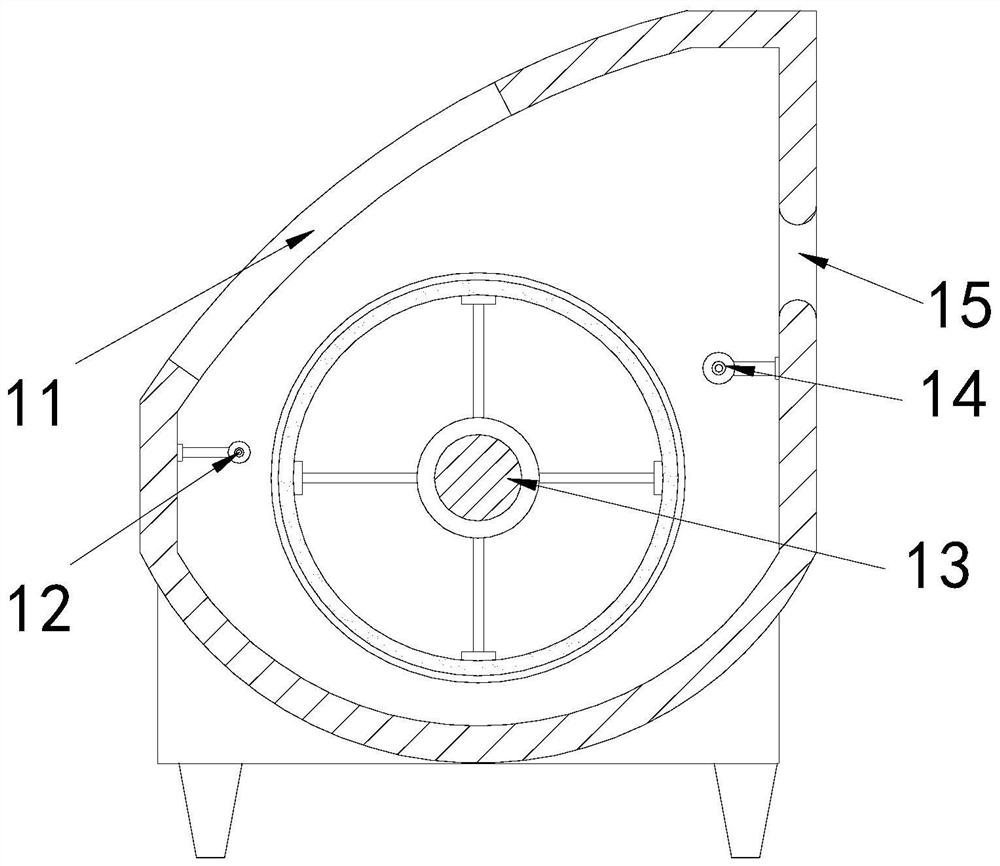

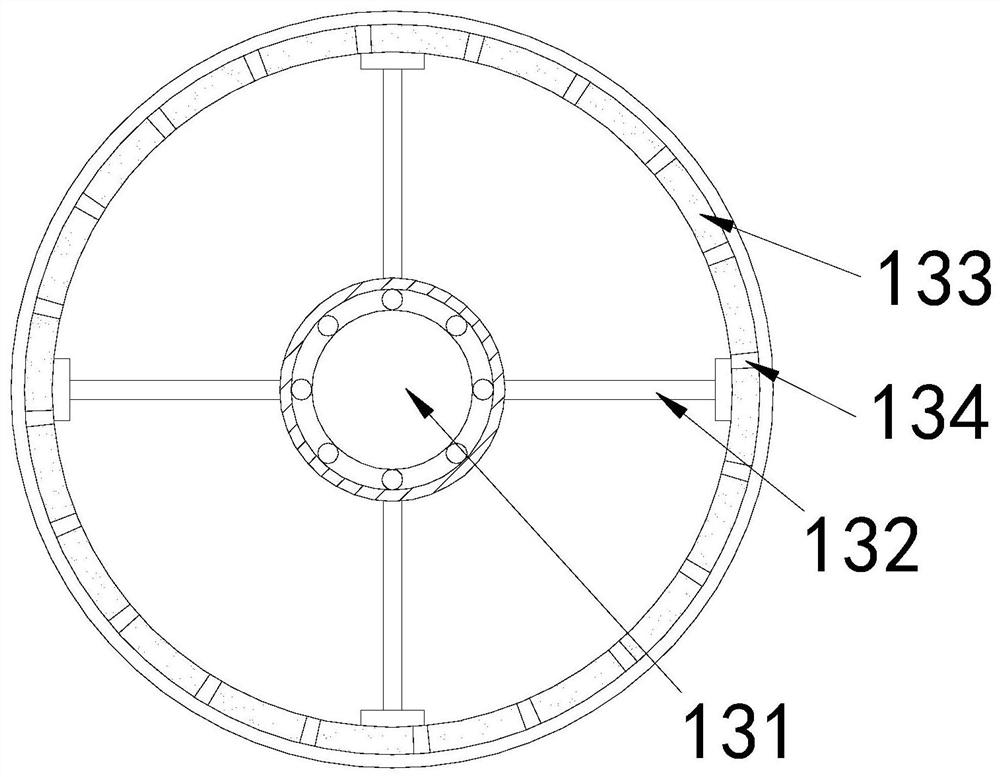

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0027] Its structure includes its structure includes main body 1, supporting foot 2, control panel 3, warning light 4, and the bottom four ends of described main body 1 are respectively provided with a supporting foot 2, and described control panel 3 is positioned at the upper front end of main body 1, so The warning light 4 is installed on the top of the main body 1, and the main body 1 includes a feed port 11, a guide roller 12, a drum 13, a material extrusion roller 14, and a discharge port 15. The feed port 11 is arranged on the top of the main body 1. At the top, the guide roller 12 is installed at the bottom of the feed port 11, the roller 13 is engaged in the middle of the main body 1, and the extruding roller 14 is installed in the middle of the rear end of the main body 1. The discharge port 15 is arranged on the upper end of the extruding roller...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The extruding roller 14 includes a supporting arm 141, an engaging block 142, a flow groove 143, and a collecting groove 144. The inner ends of both sides of the supporting arm 141 are engaged with an engaging block 142, and the engaging block 142 is embedded On both sides of the extruding roller 14, the flow groove 143 is arranged on the surface of the extruding roller 14, and the collection groove 144 is annular, and is arranged on the side end of the extruding roller 14. The width of the flow groove 143 is The extrusion roller 14 gradually narrows from the middle to both ends, which is beneficial to guiding the extruded dye.

[0034] The circulation groove 143 includes a rotating column b1, an annular body b2, a fixed rod b3, a feed groove b4, and a communication groove b5. The outer side of the rotating column b1 is provided with an annular bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com