An automatic vibration feeding device

A vibrating feeding and automatic technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of wasting processing time and long time for blanks, and achieve simple structure, obvious effect, and improve the efficiency of vibrating feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

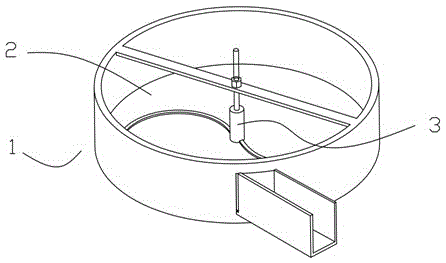

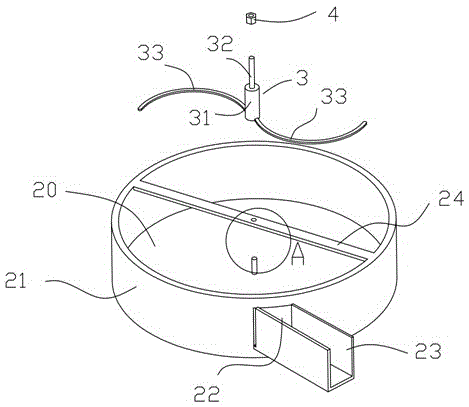

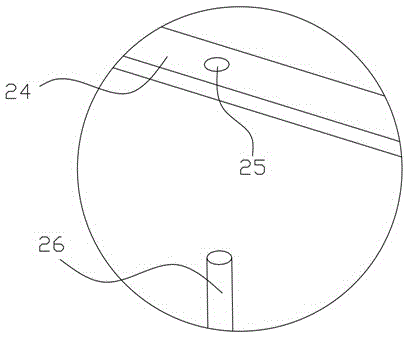

[0017] Such as Figure 1 to Figure 5 As shown, the automatic vibrating feeding device 1 includes a vibrating chamber 2, the vibrating chamber 2 includes a disc-shaped vibrating base plate 20, and an annular ring-shaped enclosure 21 is provided on the circumference of the vibrating base plate 20, and the annular enclosure 21 A discharge opening 22 is provided on the top, and a discharge trough frame 23 is provided on the discharge opening 22. A long strip-shaped fixed horizontal bar 24 is provided on the top of the annular enclosure 21, and a fixed horizontal bar 24 is provided in the center of the fixed horizontal bar. Round hole 25, the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com