Precise special-shaped stud rapid forming device and working method

A stud bolt and forming device technology, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of production efficiency restriction, high labor cost, large production cost, etc., so as to reduce labor intensity and improve production. Efficiency, the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

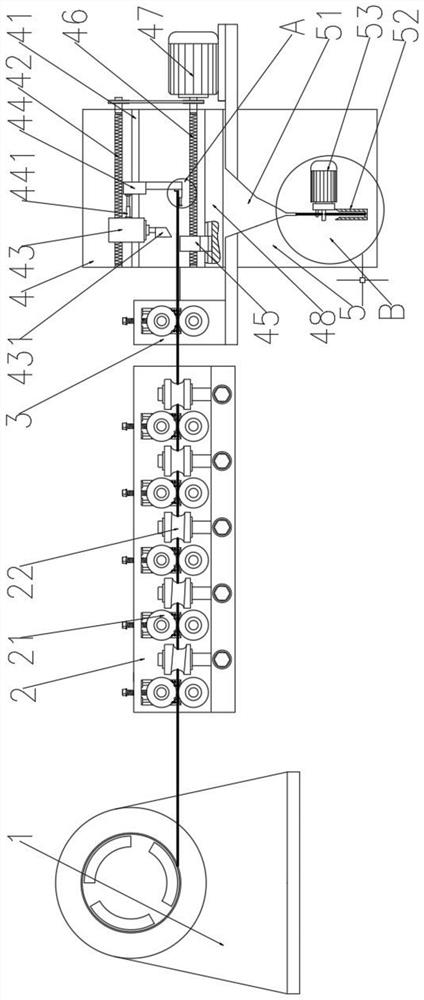

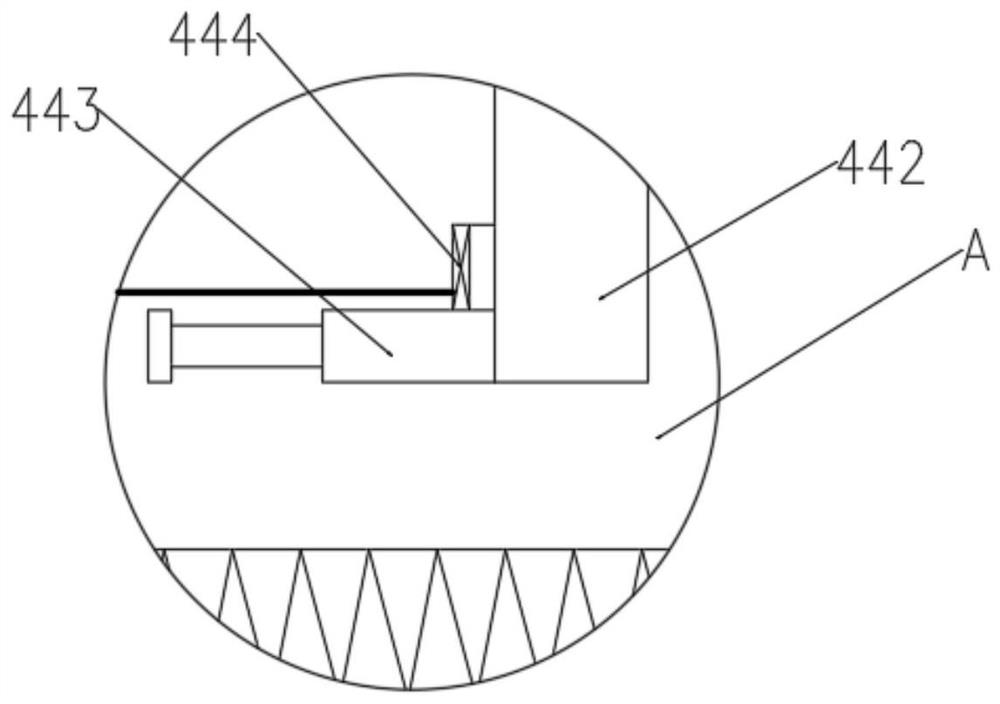

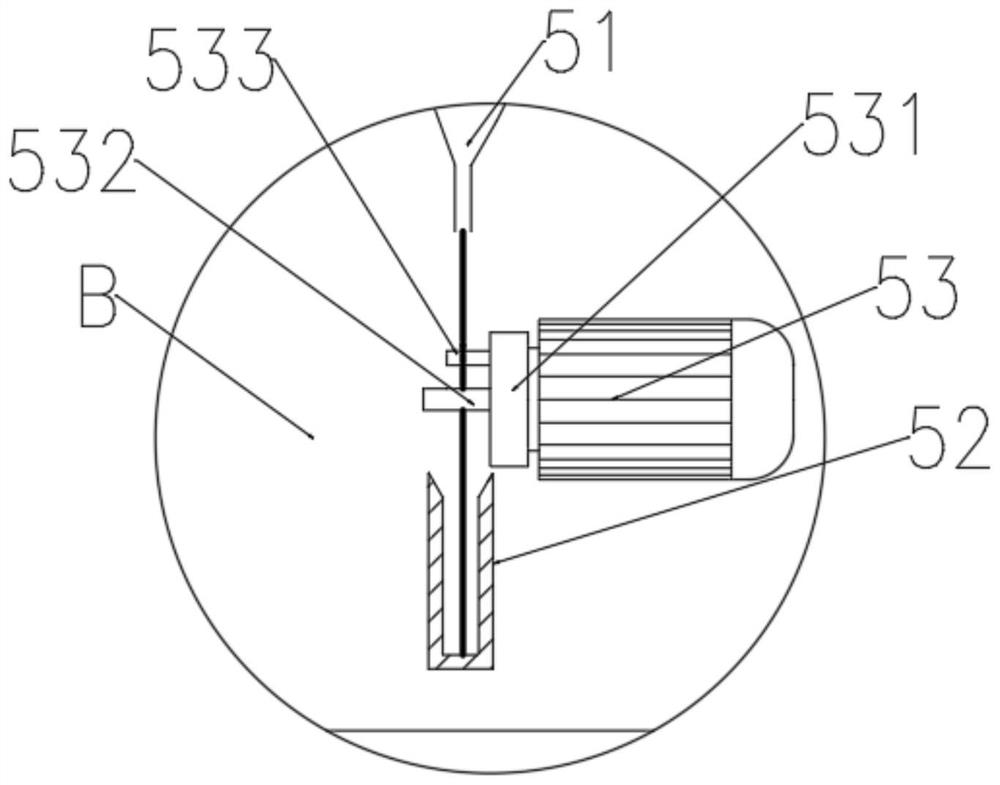

[0023] Such as Figure 1-3The precision special-shaped stud rapid prototyping device and working method shown include: uncoiler 1, straightener 2, feeding device 3, cutting device 4, bending device 5, the uncoiler 1, straightener 2. The feeding device 3 and the cutting device 4 are arranged sequentially from left to right, the bending device 5 is arranged below the cutting device 4, and the straightening device 2 is provided with multiple sets of straightening wheels 21, so The straightening wheel 21 is provided with a wheel groove 22, and the angle between the section of the wheel groove 22 and the axis of the straightening wheel 21 is decreasing; the cutting device 4 includes: a slide rail 41, a first screw mandrel 42. Cut-off cylinder 43, fixed-length device 44, lower die 45, second lead screw 46, the slide rail 41 is arranged directly below the first screw mandrel 42; the slide rail 41 and the first screw mandrel 42 are both Pass through the cutting cylinder 43, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com