Tray opening and conveying process

A technology of process and consignment, which is applied in the field of consignment and consignment technology, can solve the problems that the continuous process cannot be guaranteed, and achieve the effect of reducing the number of production workers, improving efficiency and realizing full mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

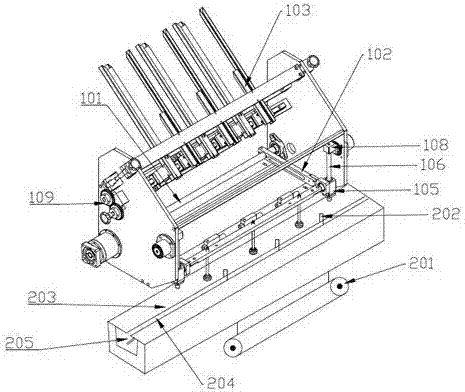

[0034] A tray opening and delivery process, comprising a tray opening step and a tray delivery step; the tray opening step is: the tray opening structure attracts the inner bottom of the tray box with the opening facing downwards and turns it over until the opening faces upwards, and places it on a Block 202 is at the tray delivery station; the tray delivery step is: the pushing block 202 pushes the tray box located at the tray delivery station to move.

[0035] Further, the unloading step can use an inclined unloading mechanism to untack, and the inclined untapping mechanism includes a drive main shaft 101 and a slewing frame 102 that can reciprocate with the drive main shaft 101; The feed bin 103 of the tray; parallel to the drive spindle 101 is provided with a swing shaft 104; the swivel frame 102 is connected with the swing shaft 104 by a slide block 105, and the slide block 105 and the swing shaft 104 are hinged; the slide block 105 Slip into the guide rod 106; the space ...

Embodiment 2

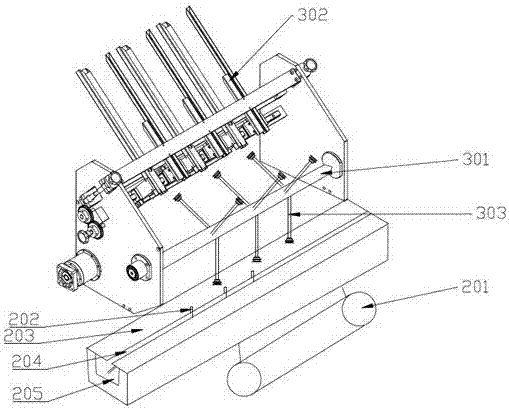

[0049] A tray opening and delivery process, comprising a tray opening step and a tray delivery step; the tray opening step is: the tray opening structure attracts the inner bottom of the tray box with the opening facing downwards and turns it over until the opening faces upwards, and places it on a Block 202 is at the tray delivery station; the tray delivery step is: the pushing block 202 pushes the tray box located at the tray delivery station to move.

[0050] Further, the untacking step can use a turntable-type untapping mechanism for untapping. The turntable-type untapping mechanism includes a driving member II and a rotating shaft 301 that can rotate with the driving member II; The feed bin II 302 of the tray; the rotating shaft 301 is provided with multiple rows of suction cups II 303 in parallel.

[0051] Further, the rotating shaft 301 rotates under the action of the driving part II, driving the suction cups II 303 of each row to rotate around the rotating shaft 301; ...

Embodiment 3

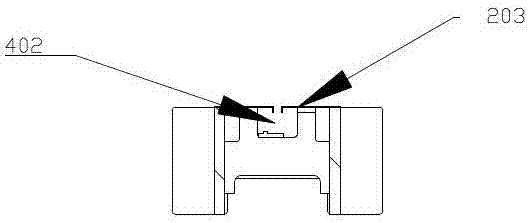

[0063] A tray opening and delivery process, comprising a tray opening step and a tray delivery step; the tray opening step is: the tray opening structure attracts the inner bottom of the tray box with the opening facing downwards and turns it over until the opening faces upwards, and places it on a Block 202 is at the tray delivery station; the tray delivery step is: the pushing block 202 pushes the tray box located at the tray delivery station to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com