Coconut rapid cutting device for beverage processing

A rapid cutting and cutting device technology, applied in application, gravity filter, shelling, etc., can solve problems such as low work efficiency and safety issues, and achieve the effect of reducing manpower and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

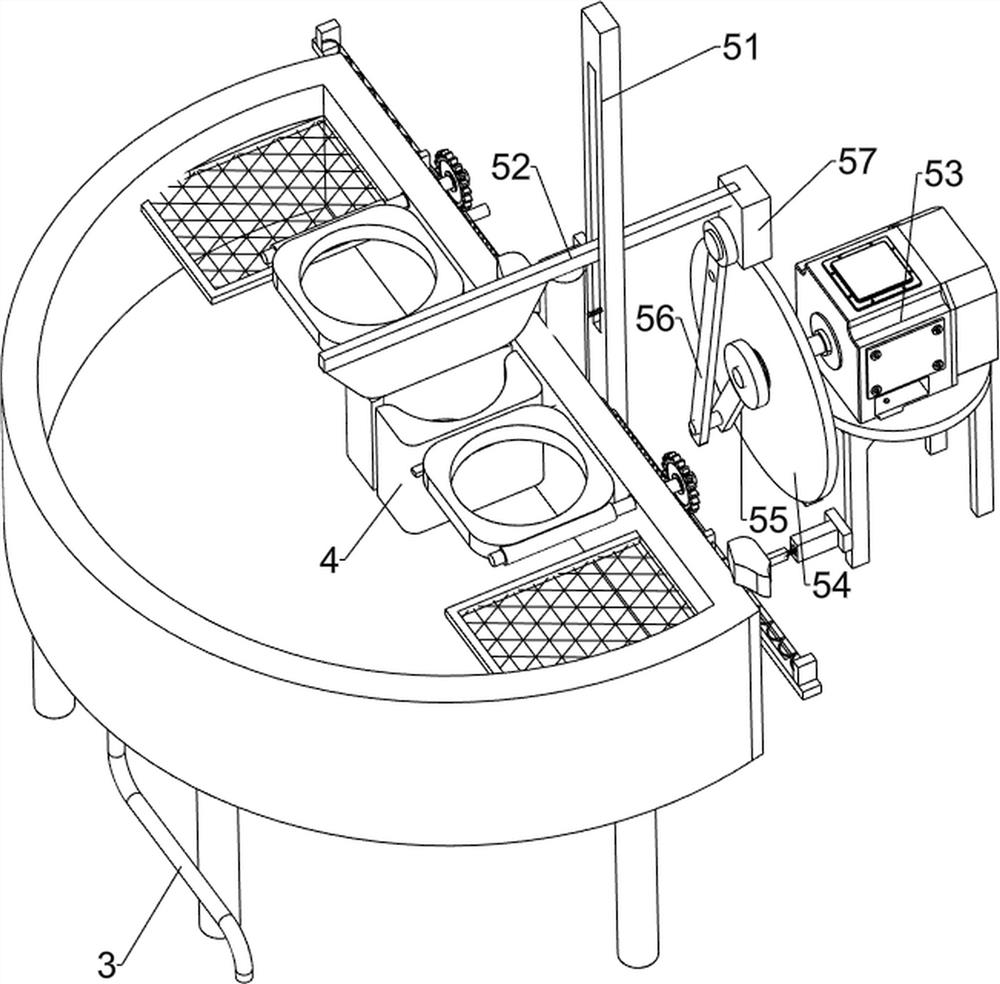

[0030] Such as figure 1 with figure 2 As shown, a quick coconut cutting device for beverage processing includes a base 1, a processing box 2, a filter screen 201, a liquid outlet pipe 3, a placement table 4, a cutting device 5 and a rotating placement device 6, and the middle part of the base 1 is provided with a processing Box 2, the inner bottom surface of the processing box 2 is an inclined surface, inclined toward the semicircular arc direction, the left side of the processing box 2 is symmetrically arranged with filter screens 201 front and rear, the center of the right side of the bottom of the processing box 2 is provided with a liquid outlet pipe 3, and the processing box 2 The left side of the inner bottom is symmetrically provided with a placement platform 4 with respect to the axis position, the cutting device 5 is provided on the left side of the top of the base 1, and a rotating placement device 6 is arranged near the straight side wall of the processing box 2, a...

Embodiment 2

[0033] Such as figure 2 with image 3 As shown, a quick coconut cutting device for beverage processing includes a base 1, a processing box 2, a filter screen 201, a liquid outlet pipe 3, a placement table 4, a cutting device 5 and a rotating placement device 6, and the middle part of the base 1 is provided with a processing Box 2, the inner bottom surface of the processing box 2 is an inclined surface, inclined toward the semicircular arc direction, the left side of the processing box 2 is symmetrically arranged with filter screens 201 front and rear, the center of the right side of the bottom of the processing box 2 is provided with a liquid outlet pipe 3, and the processing box 2 The left side of the inner bottom is symmetrically provided with a placement platform 4 with respect to the axis position, the cutting device 5 is provided on the left side of the top of the base 1, and a rotating placement device 6 is arranged near the straight side wall of the processing box 2, a...

Embodiment 3

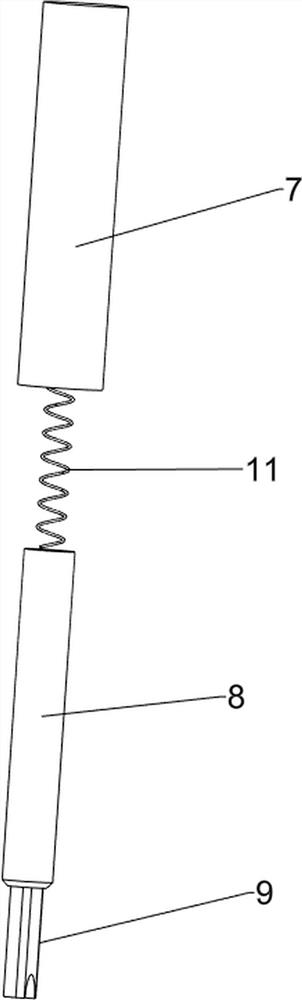

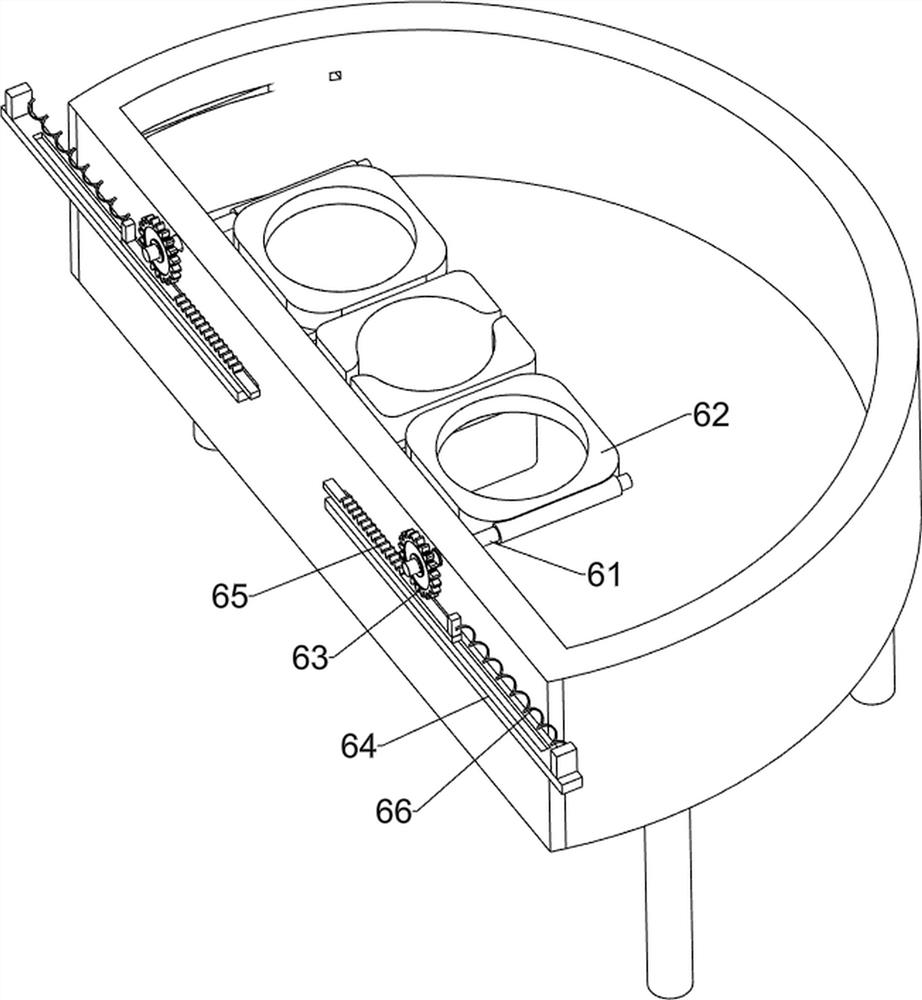

[0038] Such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 Shown, on the basis of embodiment 2, a kind of quick coconut cutting device for beverage processing also includes guide sleeve 7, sliding shaft 8, straight card bar 9, pull cord 10 and second elastic member 11, cutting knife 52 The lower part is provided with a guide sleeve 7, and a sliding shaft 8 is provided in the sliding type in the guide sleeve 7, and a straight clamping rod 9 is arranged on the lower part of the sliding shaft 8, and a stay rope 10 is connected between the two racks 65, and the inner top of the guide sleeve 7 is connected to the sliding A second elastic member 11 is connected between the tops of the shafts 8, and the second elastic member 11 is a compression spring.

[0039] When the cutting knife 52 moves downward in the guide chute plate 51, the cutting knife 52 drives the guide sleeve 7 and all parts thereof to move downward together. Moving down, the pull cord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com