Chemical anchor bolt rubber tube inserter

An inserter, chemical technology, applied in the direction of construction, building structure, building material processing, etc., can solve problems such as chemical anchor plugging, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

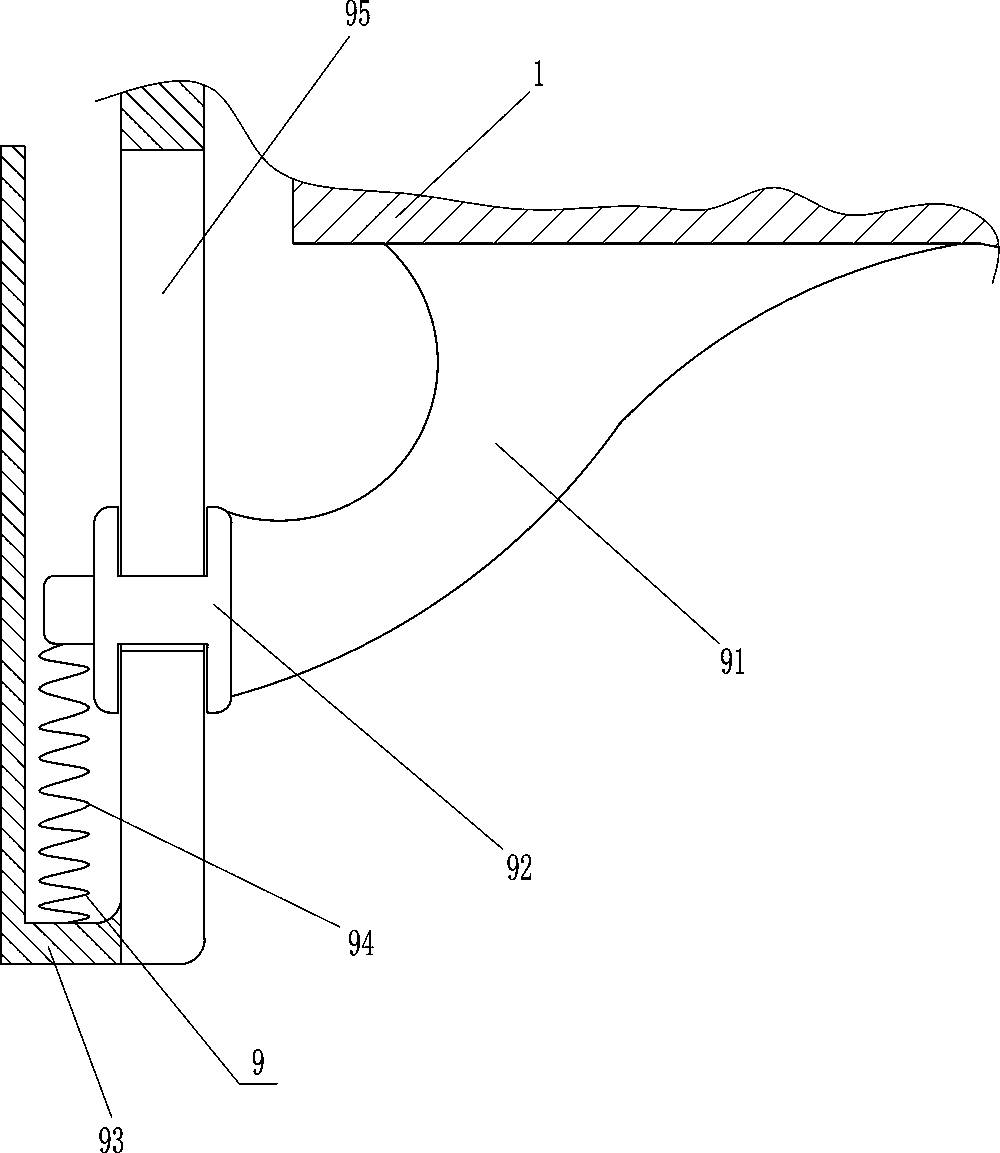

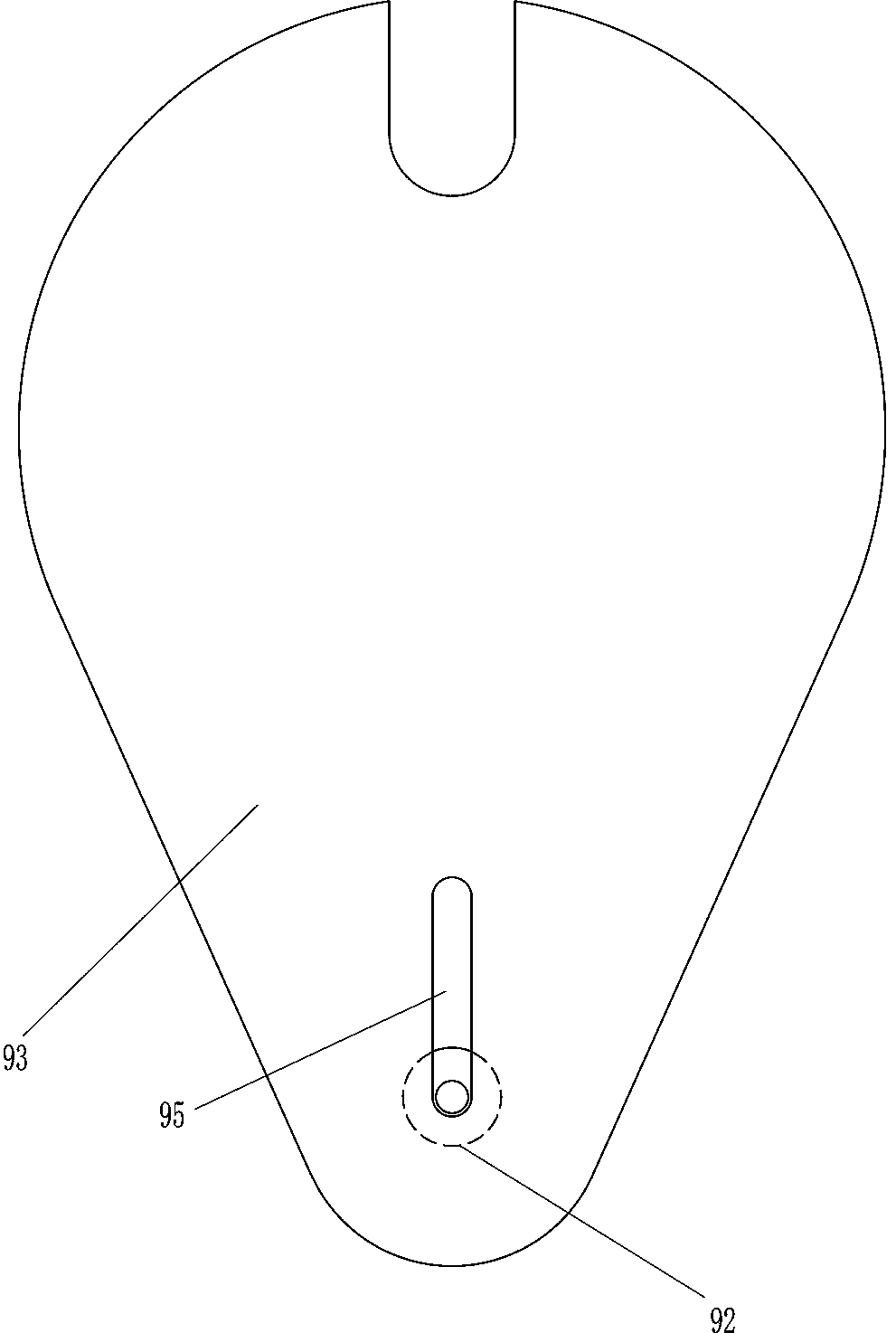

[0027] A chemical anchor hose inserter, such as Figure 1-3 and Figure 6-9 As shown, it includes a handle 1, an installation box 2, a guide shell 4, a discharge mechanism 6 and a push-out mechanism 7, the top of the handle 1 is provided with an installation box 2, and the lower part of the installation box 2 is provided with a discharge mechanism 6, and the discharge mechanism 6 It is used to store the chemical anchor bolt hose, which is convenient for the staff to take. There is a guide shell 4 on the left side of the discharge mechanism 6. The upper part of the installation box 2 is provided with a push-out mechanism 7. The push-out mechanism 7 is used to insert the chemical in the discharge mechanism 6. Anchor the hose into the hole.

[0028] It also includes a start switch 5 and a control module, the upper left side of the handle 1 is provided with a start switch 5, and the start switch 5 is connected with the control module through a line.

[0029] The discharge mechan...

Embodiment 2

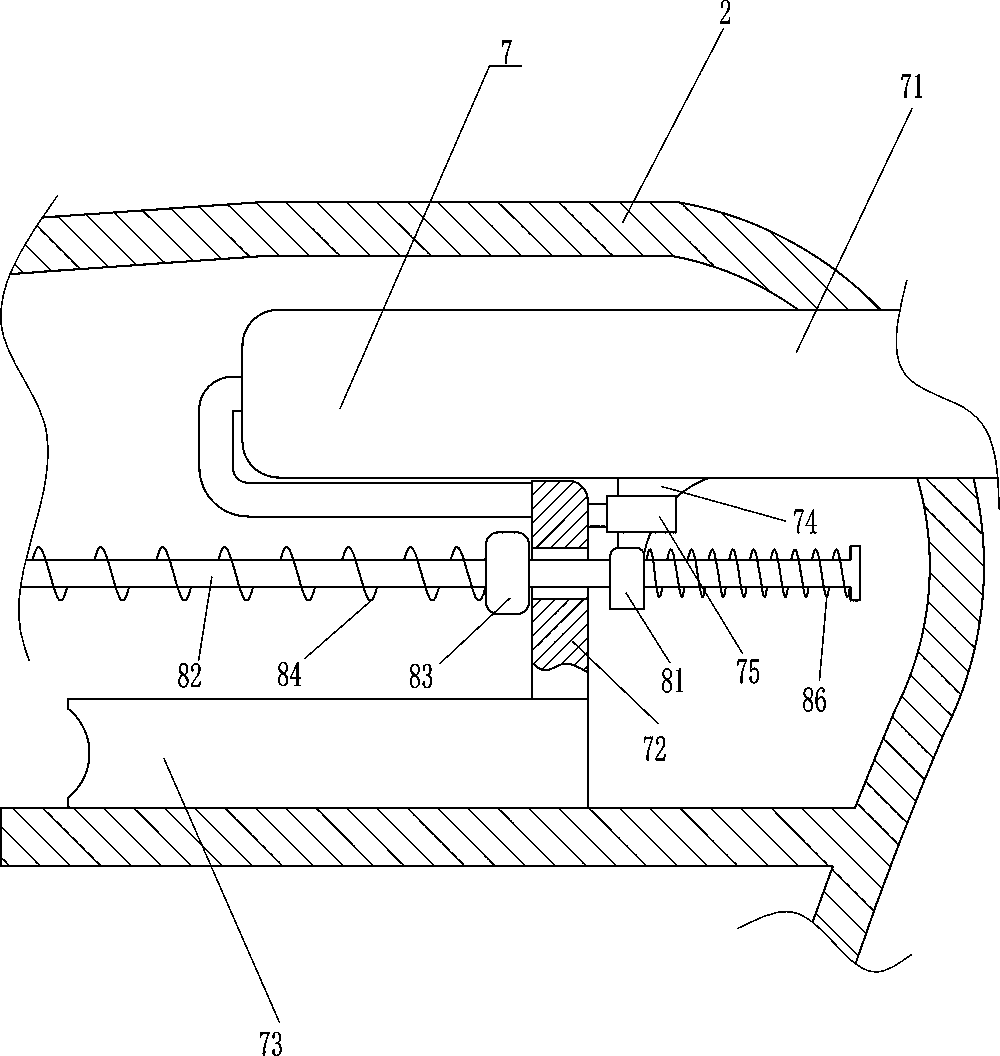

[0035] On the basis of Example 1, such as Figure 2-5 and Figure 7 As shown, a guide mechanism 8 is also included. The left part of the top wall of the installation box 2 is provided with a guide mechanism 8. The guide mechanism 8 includes a first guide sleeve 81, a guide rod 82, a sliding sleeve 83, a first spring 84, a second guide Cover 85, second spring 86, tooth bar 87, contact plate 88, first gear 89, second gear 810, spring 811, swing bar 812, spherical bar 813 and fixed plate 815, discharge pipe 76 top left sides are provided with There is a second guide sleeve 85, the bottom of the first travel switch 75 is provided with a first guide sleeve 81, the first guide sleeve 81 and the second guide sleeve 85 are slidingly provided with a guide rod 82, and the guide rod 82 passes through the middle of the push plate 72 A second spring 86 is connected between the right end of the guide rod 82 and the right side of the first guide sleeve 81, the second spring 86 is wound arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com