A ball valve auxiliary fit installation equipment

A technology for installing equipment and ball valves, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low ball embedding rate, cumbersome manual operation, affecting the production efficiency of ball valves, etc., and achieve easy collection and high ball embedding rate. , easy to embed the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

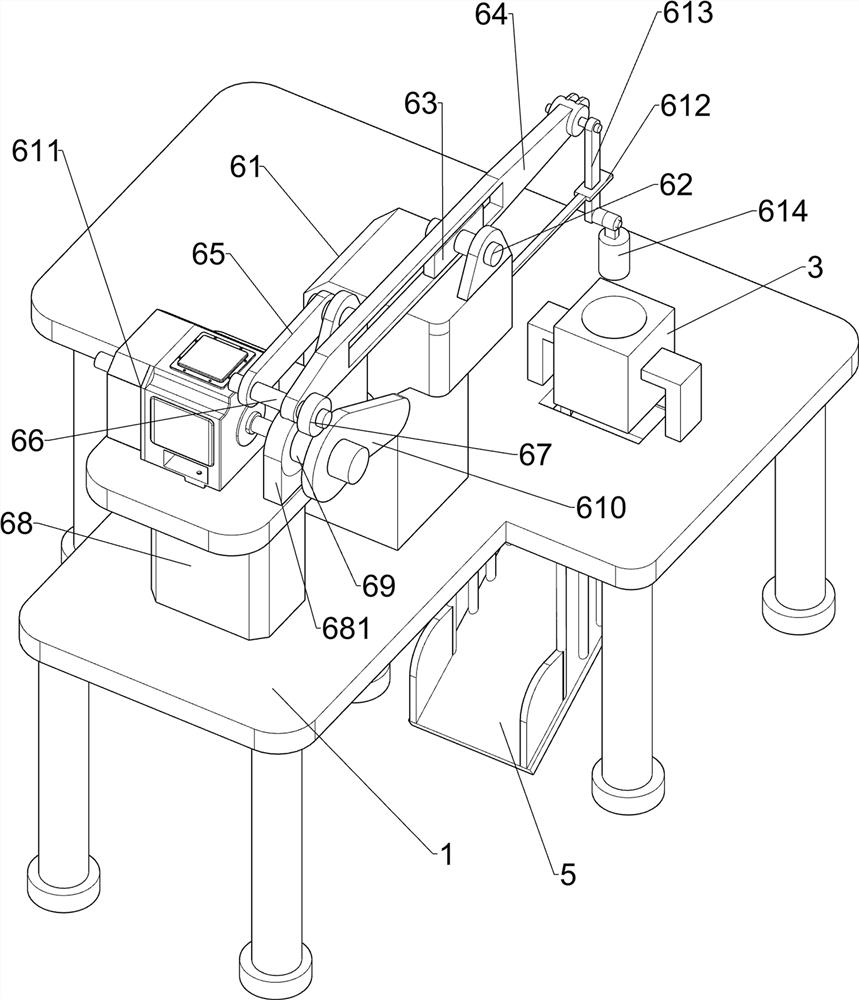

[0028] Such as Figure 1-3 As shown, a ball valve auxiliary installation equipment includes a workbench 1, a placement frame 3, a discharge mechanism 4, a pressing mechanism 6, and a slideway 5. A blanking hole 2 is opened on the right front of the top of the workbench 1, and the workbench 1. There is a placement frame 3 on the right side of the top, and the placement frame 3 is located above the blanking hole 2. The top of the workbench 1 is provided with a discharge mechanism 4. The discharge mechanism 4 is located on the left side of the placement frame 3. The bottom of the workbench 1 is provided with a slideway. 5. The slideway 5 is located below the blanking hole 2. A pressing mechanism 6 is arranged on the top of the workbench 1. The pressing mechanism 6 is located on the rear side of the discharging mechanism 4. The pressing mechanism 6 cooperates with the placement frame 3.

[0029] The discharge mechanism 4 includes a guide sleeve 41, a moving rod 42, a pull rod 43, ...

Embodiment 2

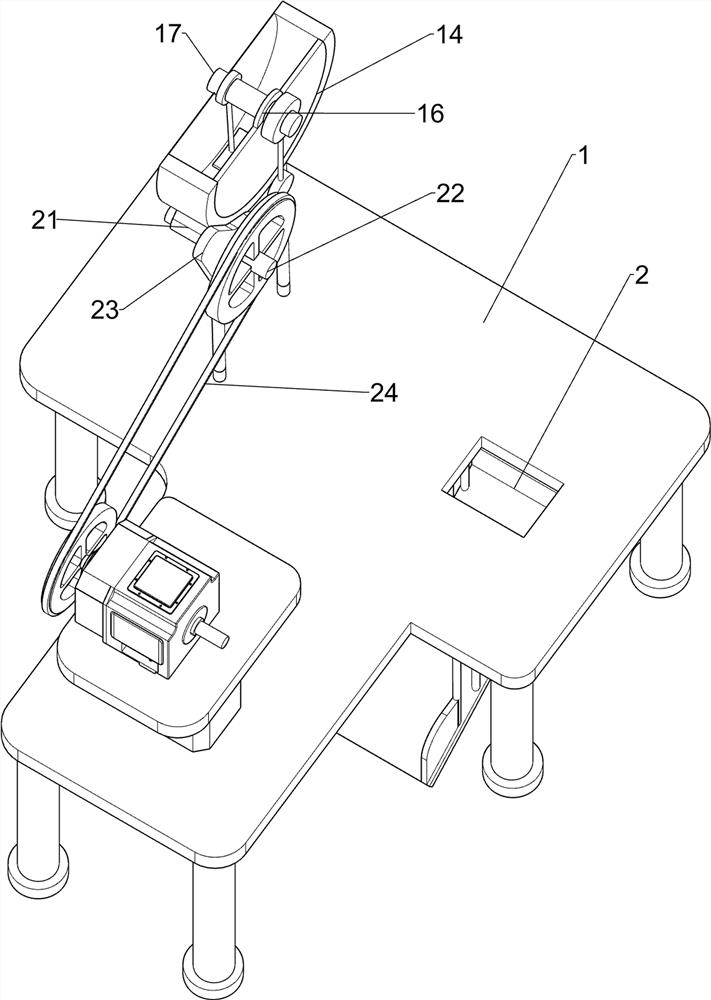

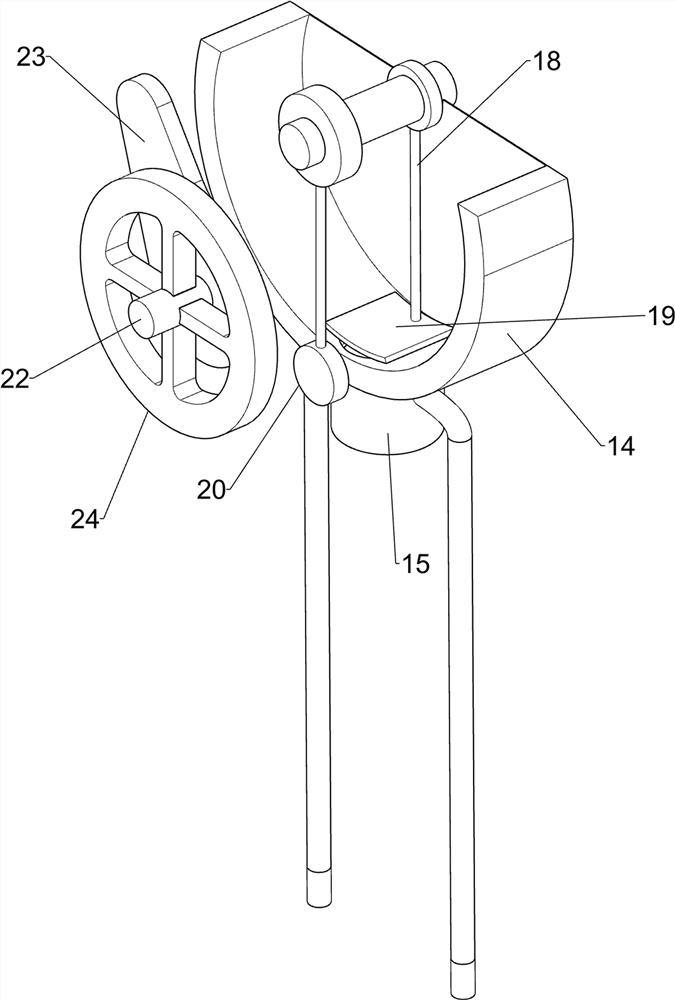

[0033] Such as Figure 4-7 As shown, on the basis of Embodiment 1, an auxiliary fitting installation device for a ball valve also includes a first bearing seat 7, a third rotating shaft 8, a second bearing seat 9, a fourth rotating shaft 10, and a fifth rotating shaft 11. The gear 12 and the crank handle 13. The right side of the top of the workbench 1 is symmetrically arranged with the first bearing seat 7 about the central axis of the placement frame 3. The two first bearing seats 7 are located on the front side of the placement frame 3. The two first bearing seats 7 are all provided with a third rotating shaft 8, and the right side of the top of the workbench 1 is symmetrically arranged with a second bearing seat 9 about the central axis of the placement frame 3. The second bearing seat 9 is located at the rear side of the placement frame 3, and the two second bearing seats 9 are provided with a fourth rotating shaft 10, the fifth rotating shaft 11 is connected between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com