Gravity type packaging and sealing equipment and method suitable for packaging ceramic tiles

A sealing equipment, self-falling technology, applied in the field of self-falling packaging and sealing equipment, can solve problems such as downtime, reduced production efficiency, increased labor intensity and midway links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

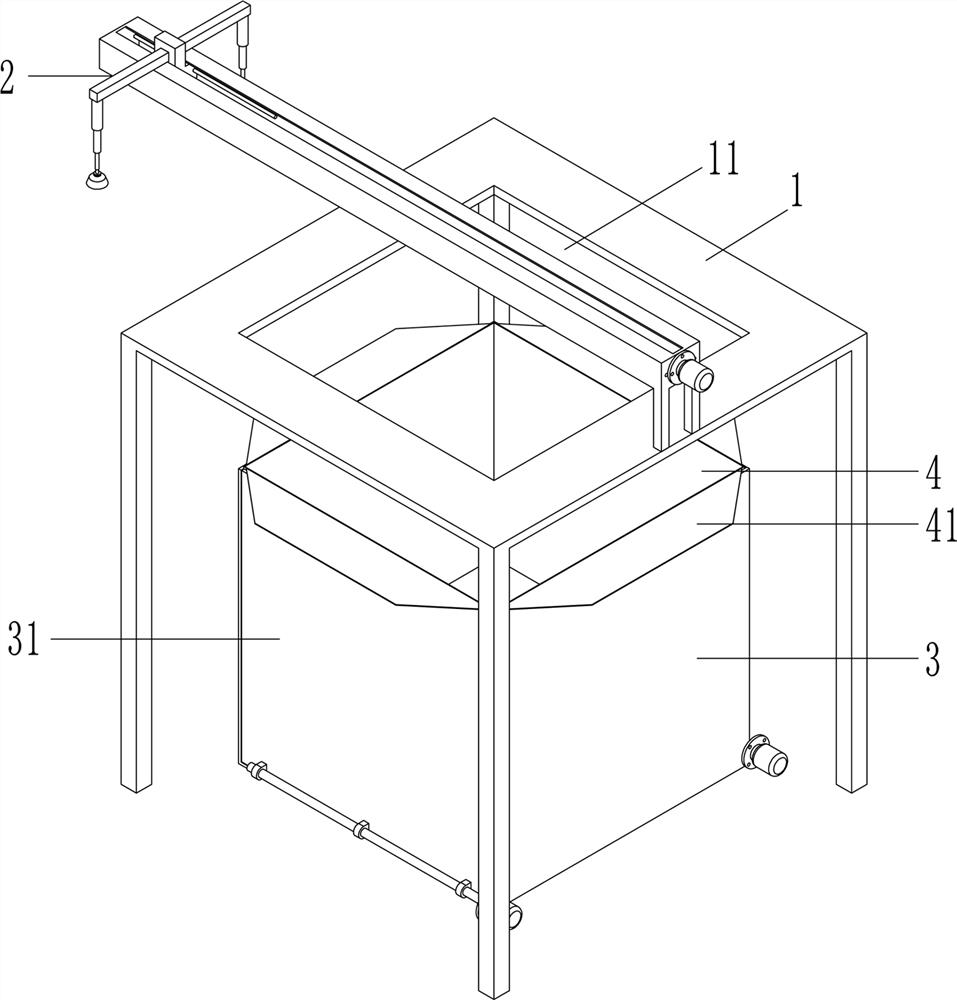

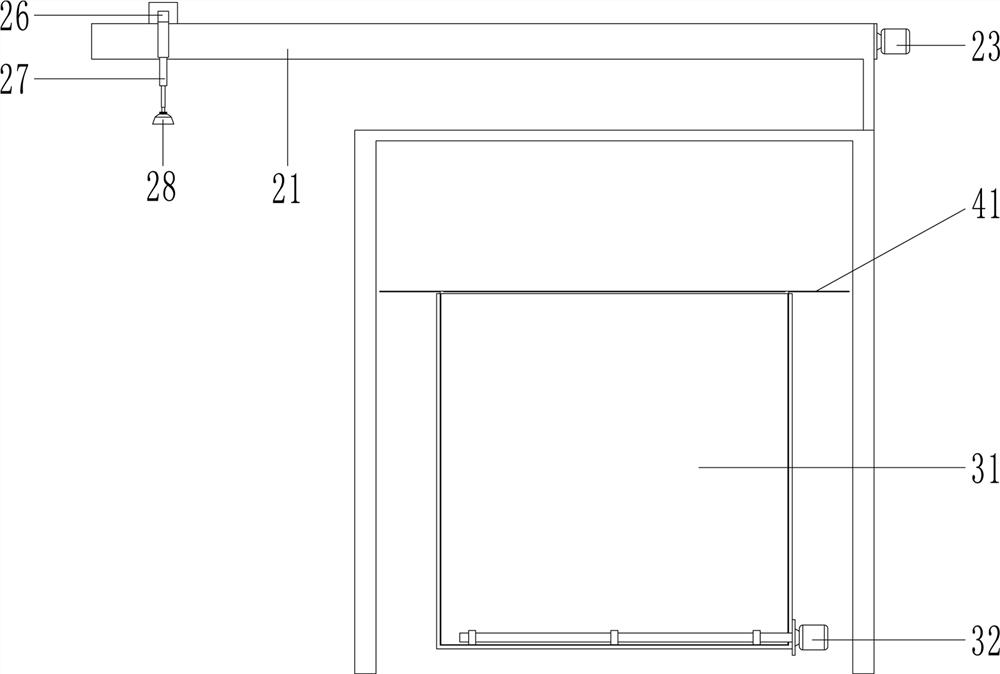

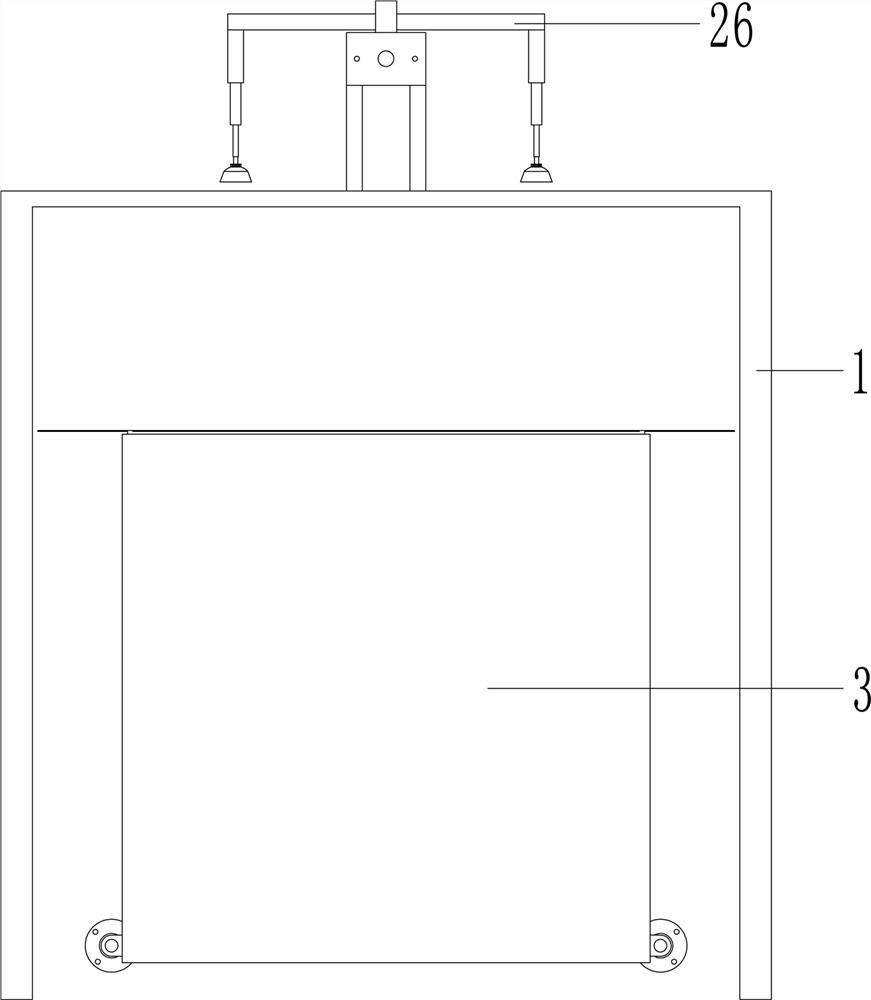

[0047] like Figure 1~Figure 13 Among them, a self-falling packaging and sealing device suitable for packaging ceramic tiles includes a rack 1, an adsorption transfer mechanism 2, an opening and closing box 3 and a packaging box 4; the adsorption transfer mechanism 2 is located on the upper part of the rack 1, and the The closing box 3 is located in the frame 1, and the packing box 4 is located in the opening and closing box 3; Corresponding to the cover hole 11 , the adsorption arm 26 moves along the cantilever 21 to the cover drop hole 11 on the outer side of the rack 1 or on the upper part of the rack 1 . When in use, when the packing box 4 is filled with tiles and enters the opening and closing box 3 from the conveyor belt, the opening and closing box 3 is closed, and the suction and transfer mechanism 2 absorbs and transfers the sealing plate 42 to make it fall into the packing box 4, so that the sealing plate 42 is covered. On the upper part of the ceramic tile in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com