Rotary seal valve for production of liquid crystal polyester

A rotary sealing valve, liquid crystal polyester technology, applied in rotary conveyors, loading/unloading, conveyors, etc., can solve problems such as the risk of jamming of rotary sealing valves, jamming, and high viscosity of liquid crystal polyester. Avoid harmful gas leakage, avoid jamming, good connection sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

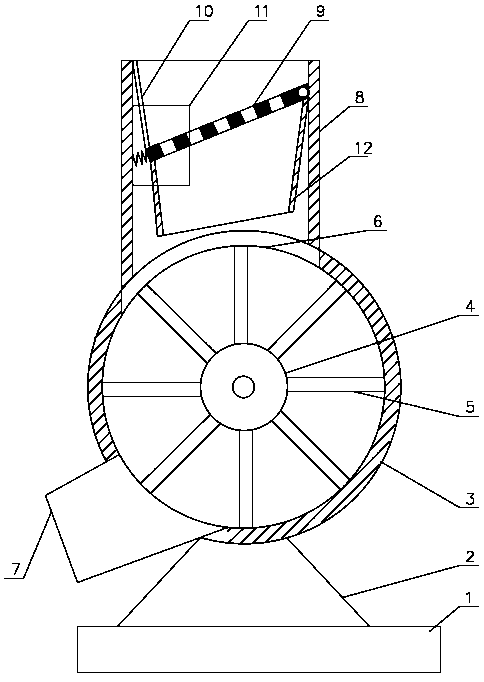

[0018] like figure 1 As shown: the rotary sealing valve for liquid crystal polyester production in this embodiment includes a trolley 1, a frame 2 is installed on the trolley, a valve body 3 is installed on the frame, and a rotor 4 is arranged inside the valve body. The rotor is formed with a material receiving trough by a set of partitions 5, the upper part of the valve body is provided with a feed port 6, the lower part of the valve body is provided with a discharge port 7, and the feed port is provided with a connecting device. The feed channel 8 inside the valve body is installed with a sieve plate 9 inclined to be installed inside the feed channel. One side of the sieve plate is connected to the inner wall of the feed channel through a rotating shaft, and the other side of the sieve plate is One side is connected to the inner wall of the feed passage by a tension spring, and the sieve plate is provided with an exciting hammer 10 on one side of the tension spring, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com