Multi-stage screening mechanism, concrete sand and gravel screening device

A sieving device and sieving technology, applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of limited sieve movement range, low sieving efficiency, and low utilization of sieving material space, achieving The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

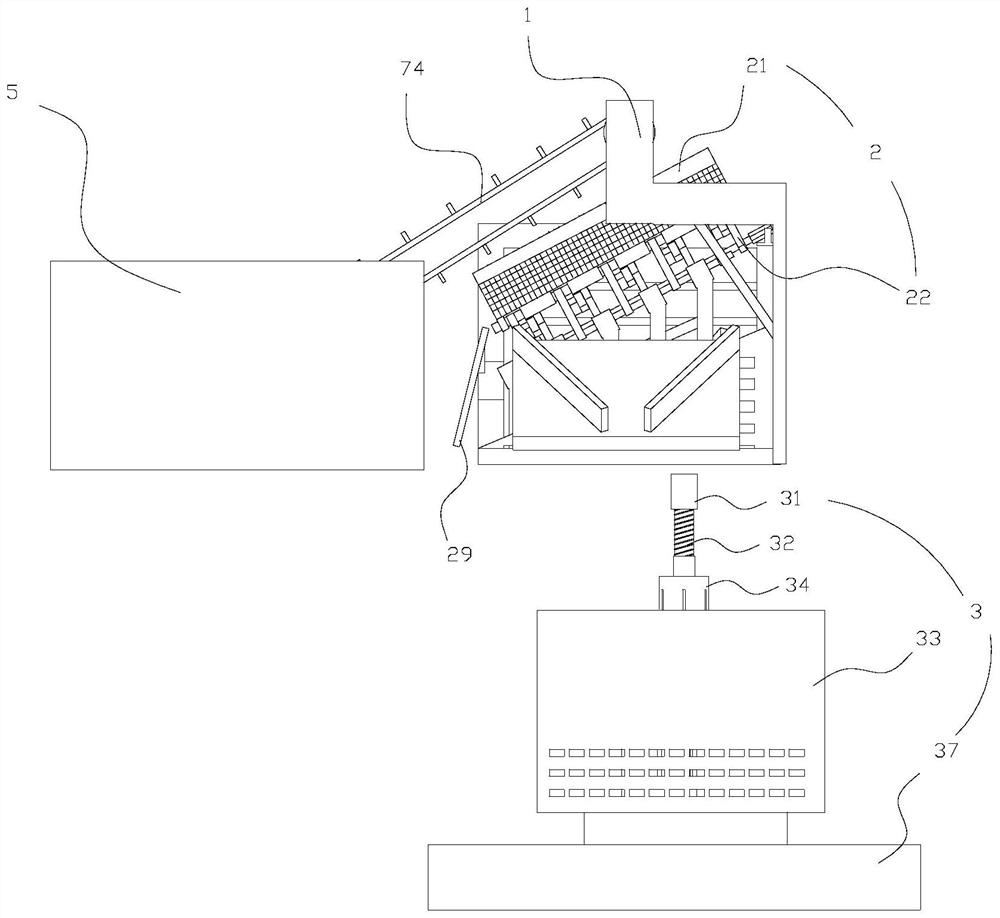

[0069] Such as figure 1 As shown, this embodiment discloses a multi-stage screening mechanism for sequential screening in space, including a frame 1 , a primary screening device 2 , and a secondary screening device 3 . The primary screening device 2 and the secondary screening device 3 are sequentially arranged on the frame 1 from top to bottom, and the secondary screening device 3 is used for secondary screening of the materials screened by the primary screening device 2 . The size of the first mesh in the first screening device 2 is greater than the size of the second mesh of the secondary screening device 3, that is, the particle size ratio of the first material falling from the first mesh in the first screening device 2 The second material falling from the second mesh of the secondary screening device 3 is a material with a large particle size.

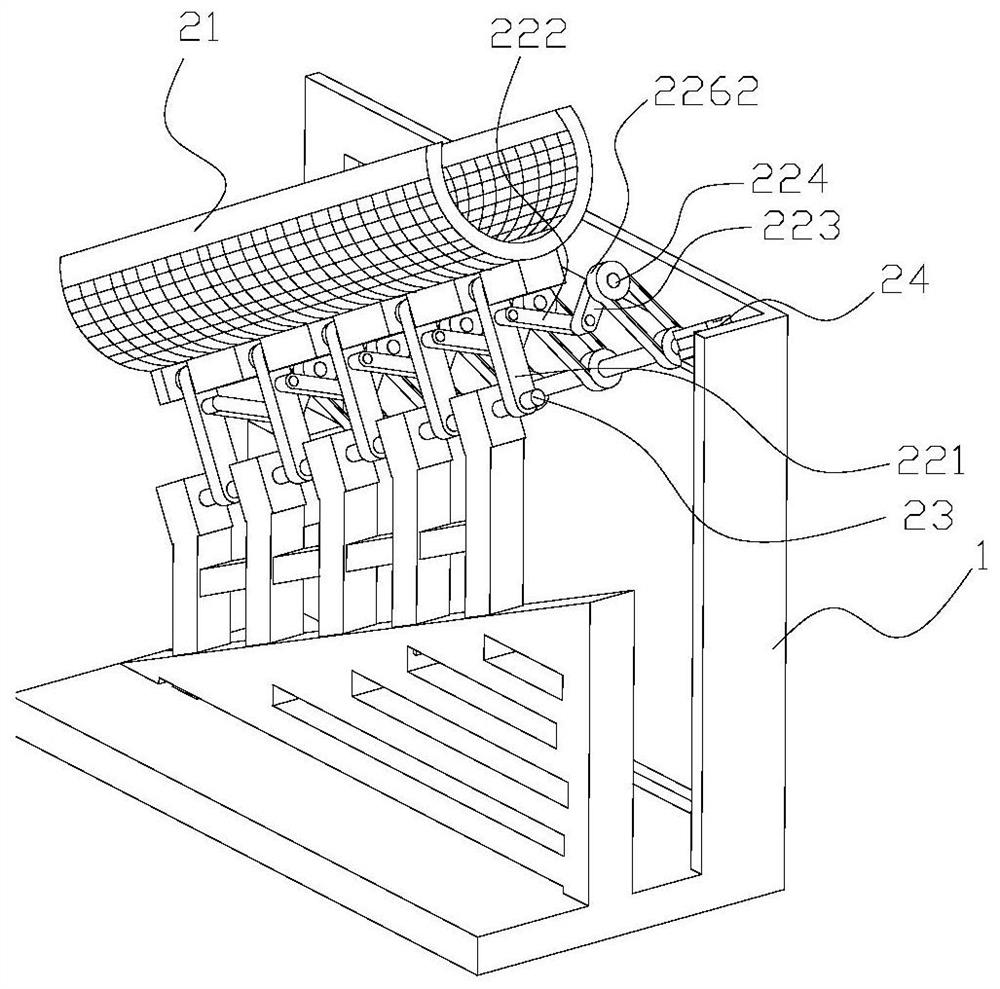

[0070] Such as Figure 1-3 As shown, the primary screening device 2 includes an upward arc screen 21, a swing mechanism 22, a ...

Embodiment 2

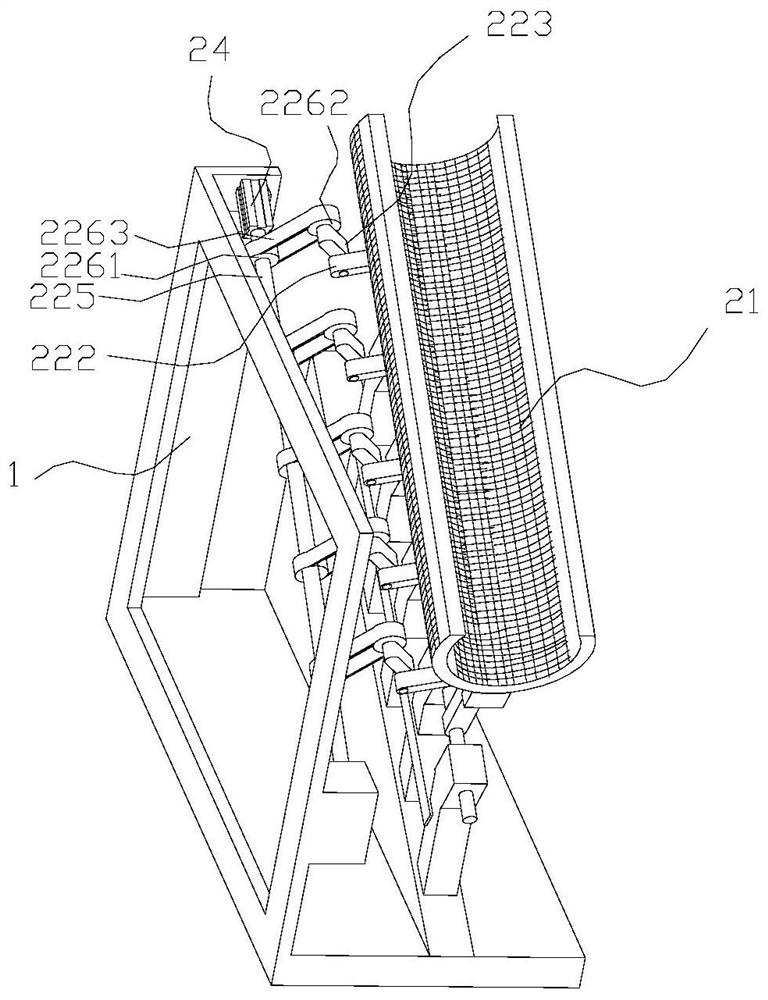

[0085] Such as figure 2 , 3 As shown, the difference between this embodiment and the above-mentioned embodiments is that there are multiple swing mechanisms 22 distributed at intervals along the length direction of the circular arc screen 21 . The other end of each third rotating arm 223 is connected with a driven shaft 224, and also includes a driving shaft 225, the driving shaft 225 is in rotation with the frame 1, and the end of the driving shaft 225 is connected with the output shaft of the first drive motor 24, The transmission between the driving shaft 225 and each driven shaft 224 is respectively through a set of transmission components. The transmission assembly of the present invention can be the belt transmission device of prior art, comprises primary screening driving pulley 2261, primary screening driven pulley 2262, primary screening belt 2263, primary screening primary pulley 2261 is connected on the drive shaft 225 , the primary screening driven pulley 2262 i...

Embodiment 3

[0088] Such as Figure 10 , 11 As shown, the difference between this embodiment and the above-mentioned embodiments is that it also includes a climbing type scraper conveying device and a stacking bin 5 . The opening of the accumulation bin 5 is upward for accumulating the materials to be screened. The lower end of the climbing-type scraper conveying device is limited in the accumulation bin 5, and the higher end of the climbing-type scraper conveying device is exposed to the opening of the accumulation bin 5 and extends upwards, from the climbing-type scraper conveying device The falling material can fall into it through the opening end of the circular arc screen cloth 21 .

[0089] The climbing type scraper conveying device comprises a feeding motor 71, a feeding driving wheel 72, a feeding driven wheel (not shown in the figure), and a feeding belt 74. The driven wheel can be connected on the feeding driven shaft, and the two ends of the feeding driven shaft are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com