A kind of biomass fermentation reaction device and its application

A technology of biomass fermentation and reaction device, applied in the field of microbial fermentation, can solve the problems of large area of fermentation tank, low processing capacity, low fermentation efficiency, etc., and achieve the effects of low cost, easy operation and improved fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

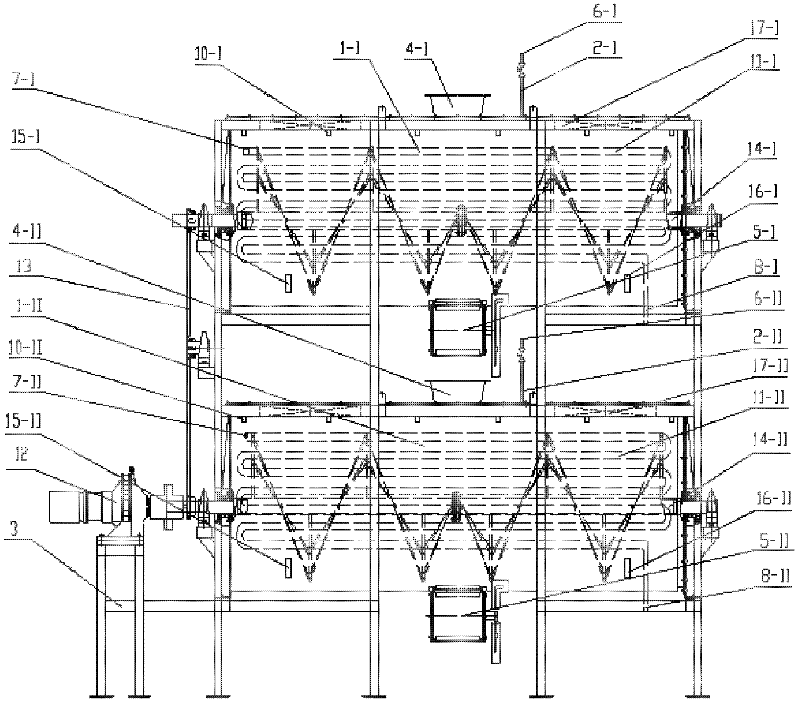

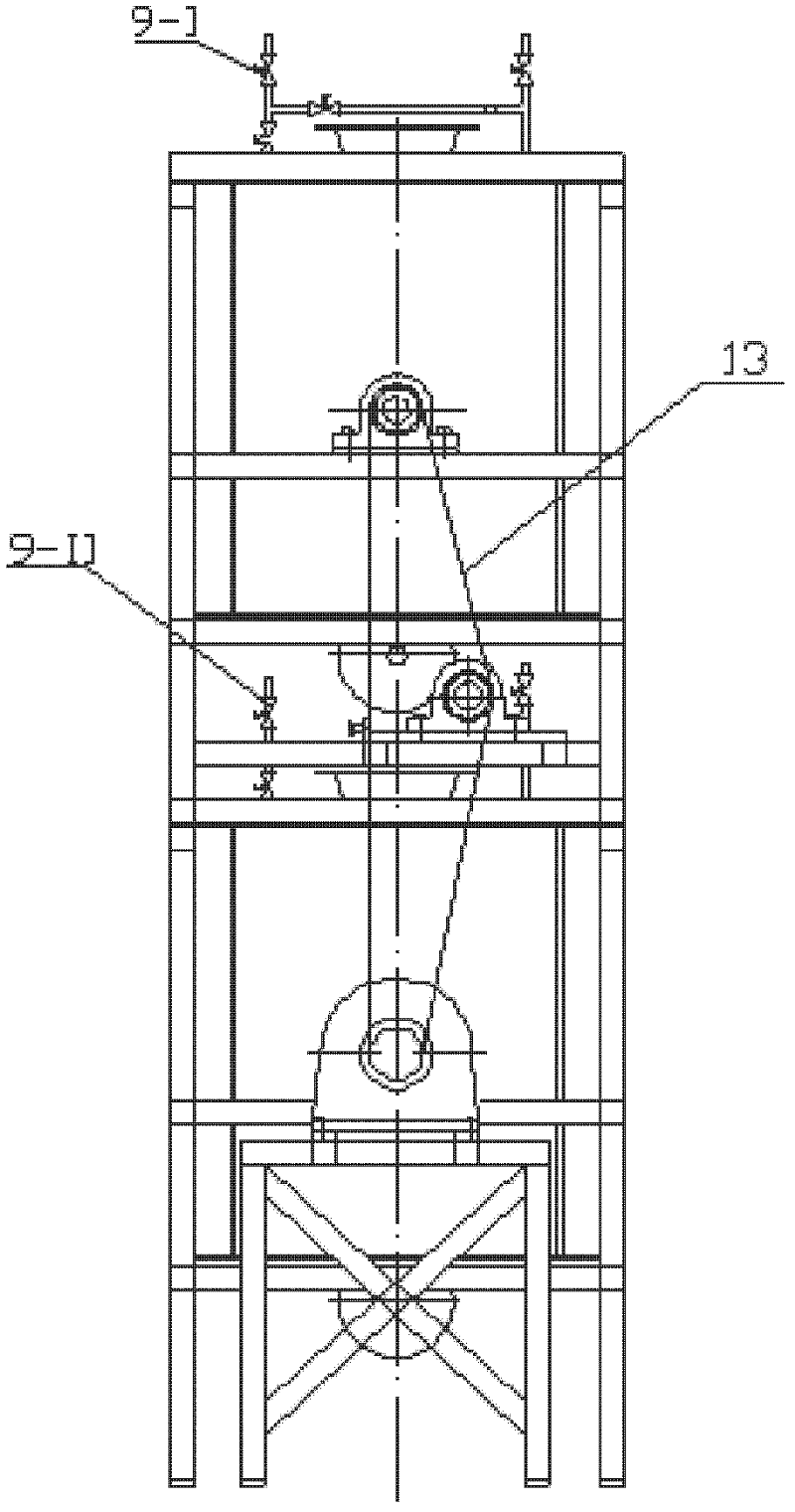

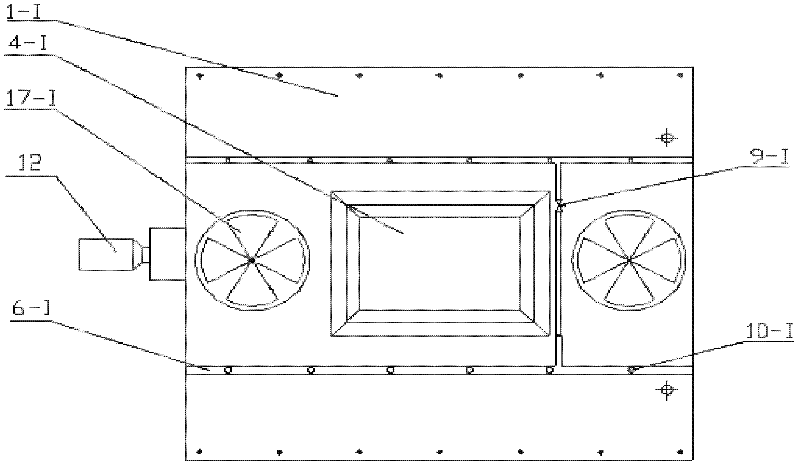

[0030] A biomass fermentation reaction device, consisting of fermentation reactors 1-I, 1-II, liquid feeding pipes 2-I, 2-II, heating device, stirring device, temperature measuring device, humidity measuring device and support 3, the fermentation The reactor includes the upper fermentation reactor 1-I and the lower fermentation reactor 1-II. The fermentation reactor is a cuboid box structure and fixed on the support in a stacked shape. The upper fermentation reactor 1-I and the lower fermentation reactor 1 -II have the same structure and size, the front wall and rear wall of fermentation reactor 1-I and 1-II are interlayer structures, and fermentation reactor 1-I and 1-II are respectively equipped with material inlets 4-I and 4- Ⅱ and outlets 5-I and 5-II, inlets 6-I and 6-II of liquid feeding pipes, inlets 7-I and 7-II of heating pipes and outlets 8-I and 8-II; feeding pipes 2-I and 8-II 2-II is equipped with valves 9-I and 9-II respectively to control the addition of bacteri...

Embodiment 3

[0044] An application of the above-mentioned biomass fermentation reaction device, adopting one-time addition of bacterial liquid and two-step fermentation method to carry out biomass fermentation reaction, the steps are as follows:

[0045] 1) Add 25 cubic meters of crushed wheat straw with a particle size of 3 mm to the upper fermentation reactor, start the agitator and exhaust fan;

[0046] 2) Add 9L of bacterial liquid and 40L of water to the upper fermentation reactor through the liquid feeding pipe under stirring state and continue to stir for 4 minutes. ;

[0047] 3) Turn off the agitator and the exhaust fan, display the temperature and humidity of the material through the thermometer and the hygrometer, use the solar heater to supply heat to the upper fermentation reactor to keep the temperature at 55°C, and use the liquid addition pipeline to replenish water to keep the humidity at 50%;

[0048] 4) During the fermentation process, the stirrer is stirred once every 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com