Recycled concrete mixer capable of improving mixing uniformity

A technology for recycling concrete and mixing uniformly, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of affecting the uniformity of concrete and easy to deposit at the bottom of the mixing drum, and achieve uniform mixing and improvement of concrete. Uniformity, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

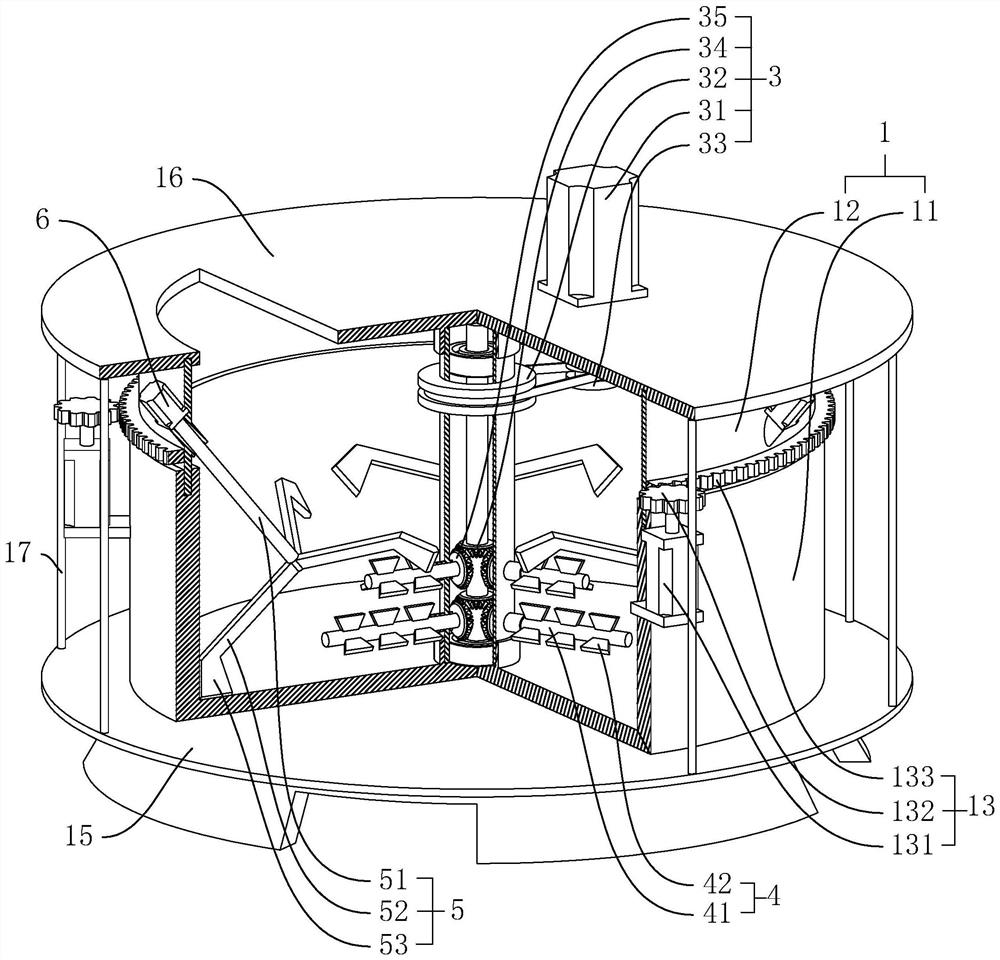

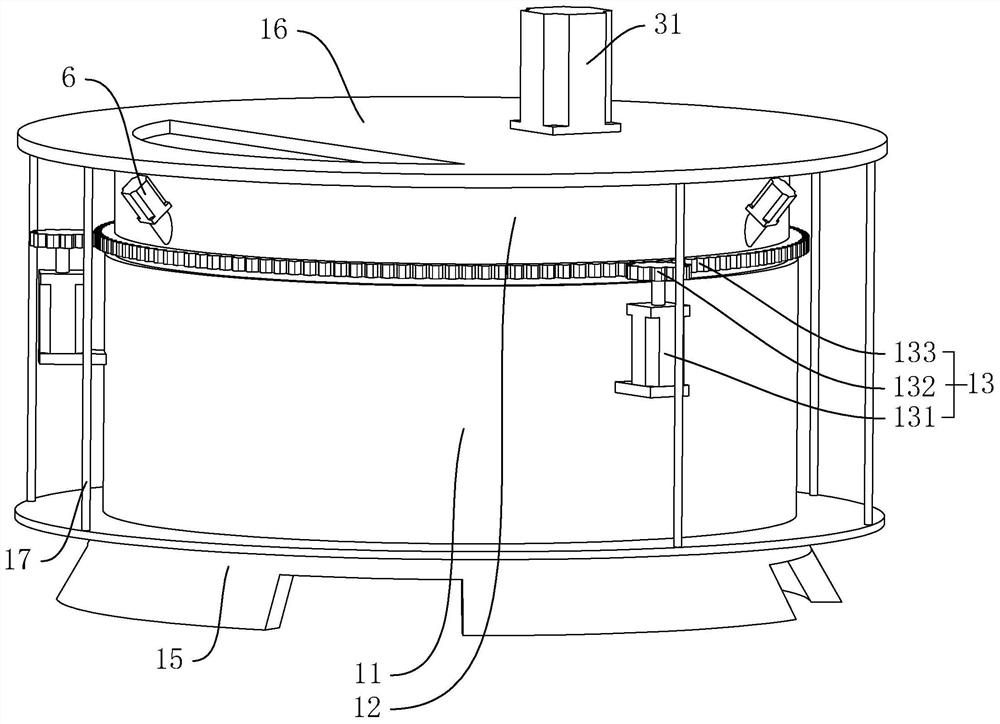

[0038] refer to figure 1 , which is a recycled concrete mixer for improving mixing uniformity disclosed by the present invention, comprising a mixing drum 1, a stirring shaft 2 vertically arranged inside the mixing drum 1, two sets of stirring paddles 4 rotating with the stirring shaft 2, and a The stirring shaft 2 and the stirring paddle 4 rotate the first drive mechanism 3 and three sets of turning mechanisms 5 arranged inside the stirring drum 1 .

[0039] refer to figure 2 , the lower end of the mixing drum 1 is fixedly connected with a base 15, which is used to enhance the stability of the mixing drum 1; a support plate 16 is also provided above the mixing drum 1, and the support plate 16 is fixedly connected with the base 15 through eight connecting rods 17, eight The connecting rods 17 are evenly distributed along the circumferential direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com