Stir-frying device for nut processing

A technology for stir-frying and nuts, which is applied to the field of stir-frying devices for nut processing, can solve the problems of low frying efficiency and insufficient turning effect of nuts, and achieves the effects of sufficient stir-frying, improved turning range, and full and comprehensive turning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

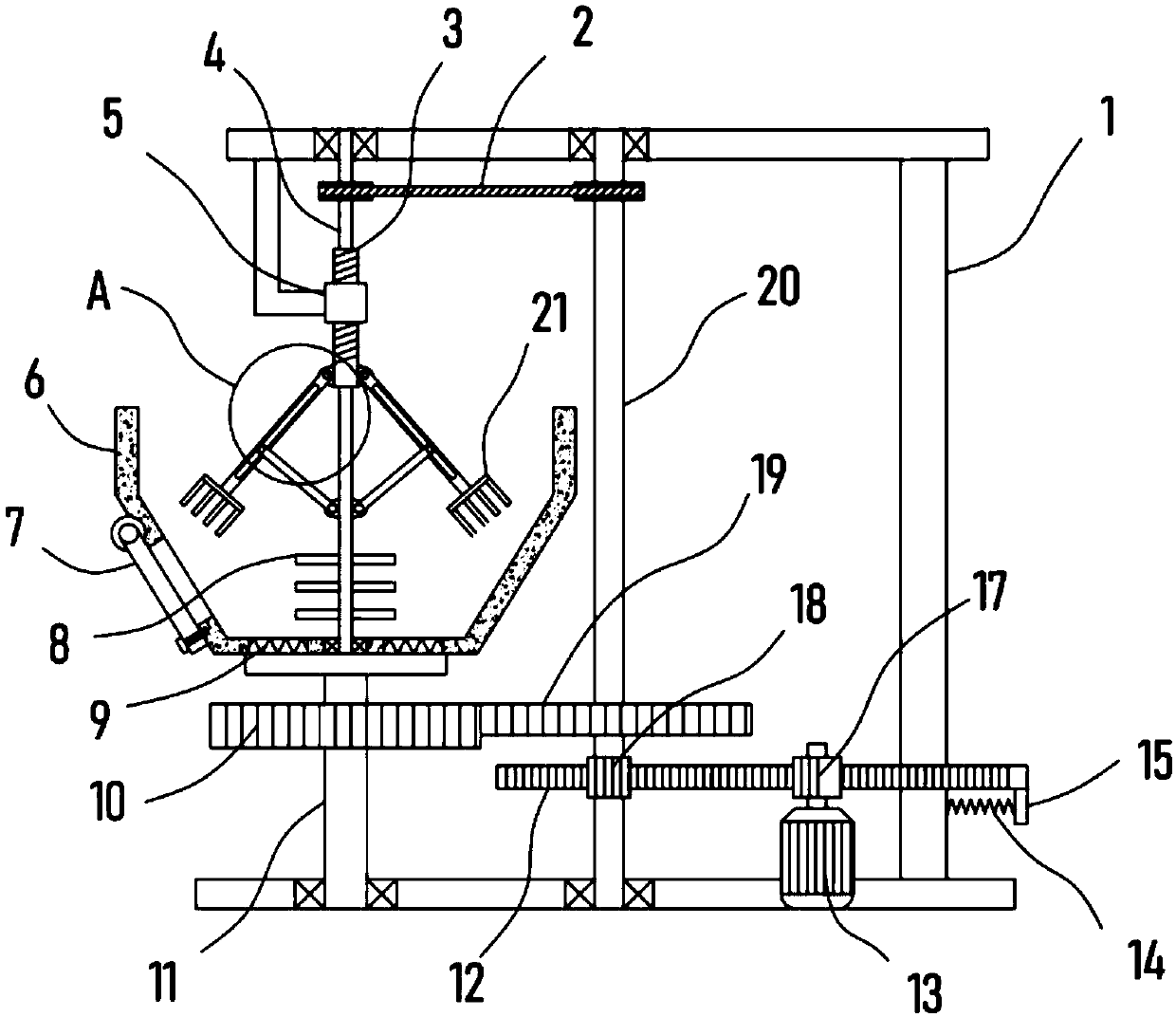

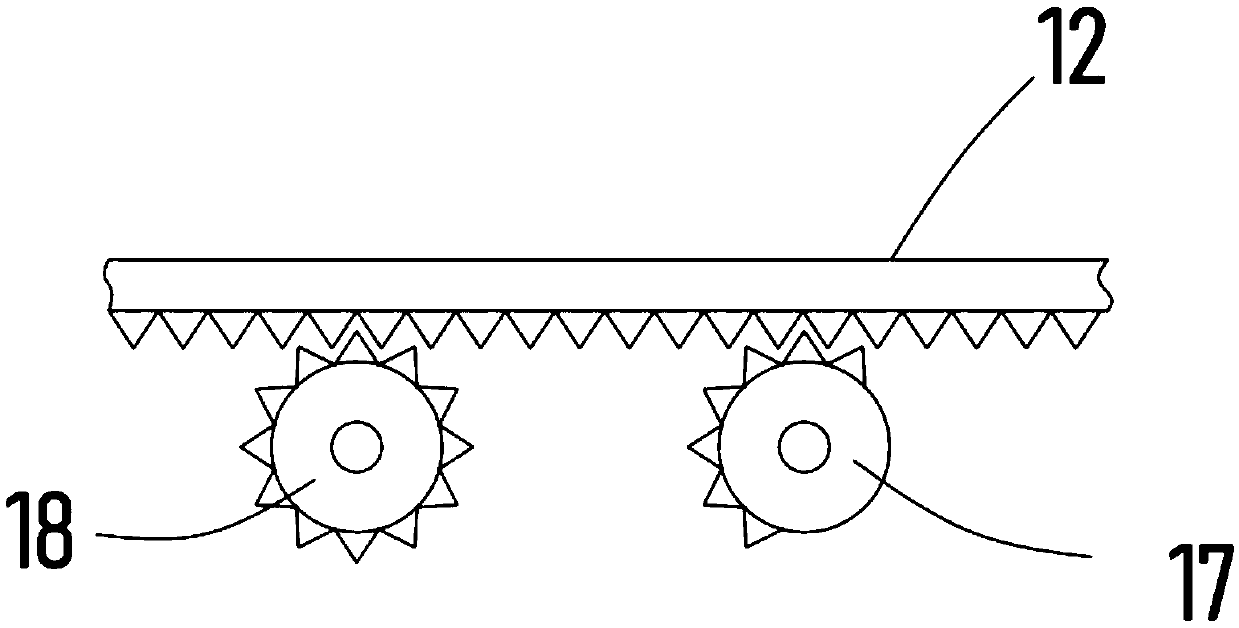

[0021] see Figure 1-3 , a stir-frying device for processing nuts, comprising a support frame 1, a frying tank 6 is rotatably installed in the support frame 1, a rotating shaft 11 is vertically arranged at the bottom of the frying tank 6, and a rotating shaft 11 is installed vertically in the bottom of the frying tank 6. A heater 9 is installed, and the frying tank 6 is used to place nuts to be roasted. The heater 9 heats the frying tank 6 from the bottom to achieve the required temperature for frying the nuts.

[0022] On the support frame 1, the rotating type is vertically provided with a driven shaft 4 extending downwards into the frying tank 6, and several flipping plates 8 are evenly fixed on the surface of the driven shaft 4, and the rotation of the driven shaft 4 can drive the flipping rotation. The plate 8 rotates, and then realizes the rotation and dispersion of the nuts in the frying tank 6, promotes the uniform heating of the nuts, and improves the effect of frying....

Embodiment 2

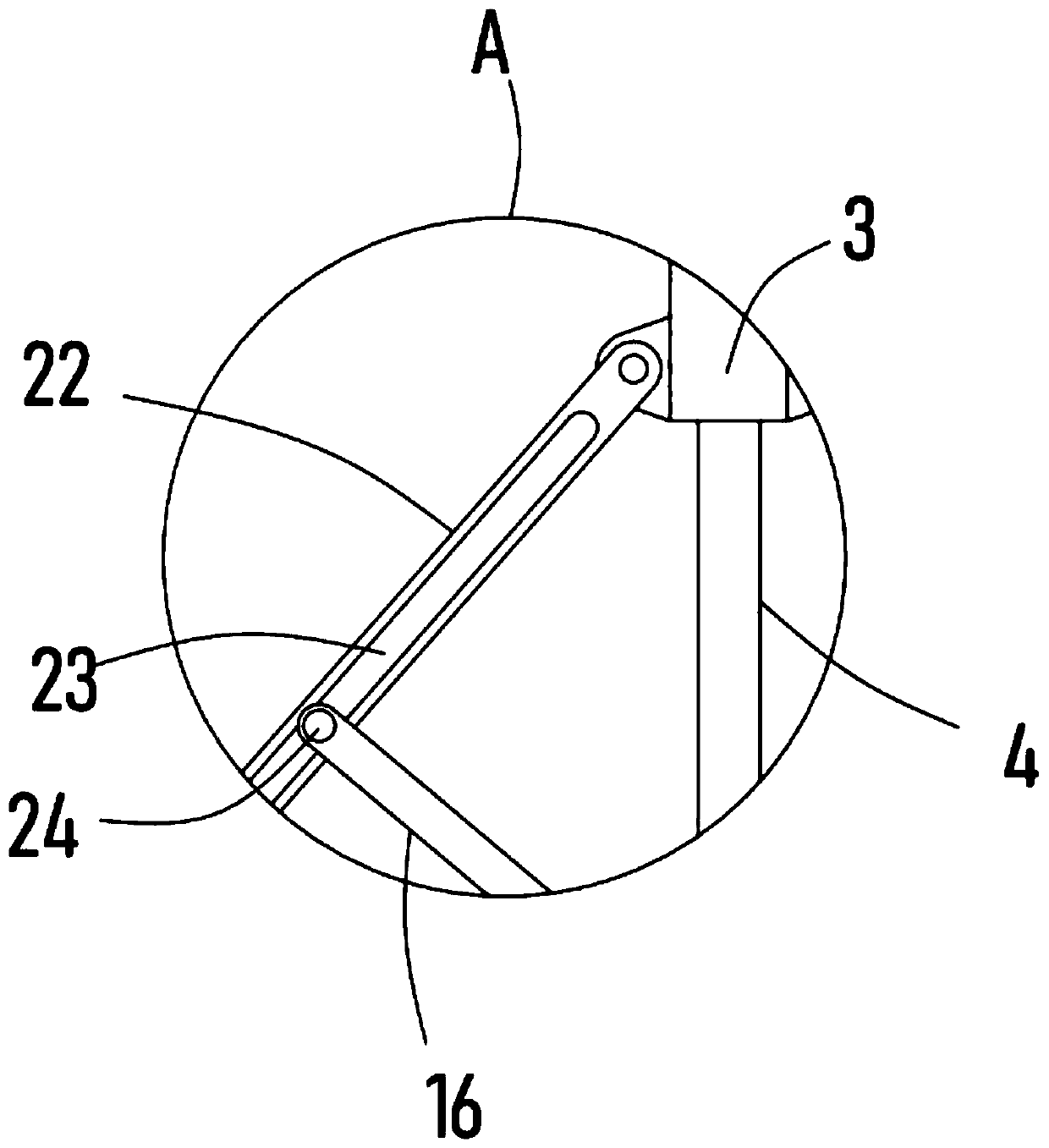

[0025] On the basis of Embodiment 1, in addition, an externally threaded pipe 3 is movably sleeved on the driven shaft 4, and a swing plate 22 is symmetrically hinged on the lower side wall of the externally threaded pipe 3, and a stirring frame 21 is fixedly installed on the lower end of the swing plate 22. The rotation of the moving shaft 4, the side wall of the driven shaft 4 is hinged with a support rod 16, the side wall of the swing plate 22 is provided with a bar-shaped hole 23 along its length direction, and the upper end of the support rod 16 is fixed with a slide embedded in the bar-shaped hole 23 for transmission. Pin shaft 24.

[0026] The rotation of the driven shaft 4 can drive the support rod 16 to rotate, and then realize that the swing plate 22 drives the stirring frame 21 fixed thereon to rotate and further stir fry the nuts in the frying tank 6 .

[0027] Further, the externally threaded pipe 3 is fitted with an internally threaded pipe 5 fixed on the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com