Washing machine and washing method

A washing machine and washing tub technology, which is applied in the field of washing machines, can solve the problems of increasing the amount of detergent, uneven washing, and low washing efficiency, and achieves a relatively small reciprocating rotation range, improved washing uniformity, and improved washing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

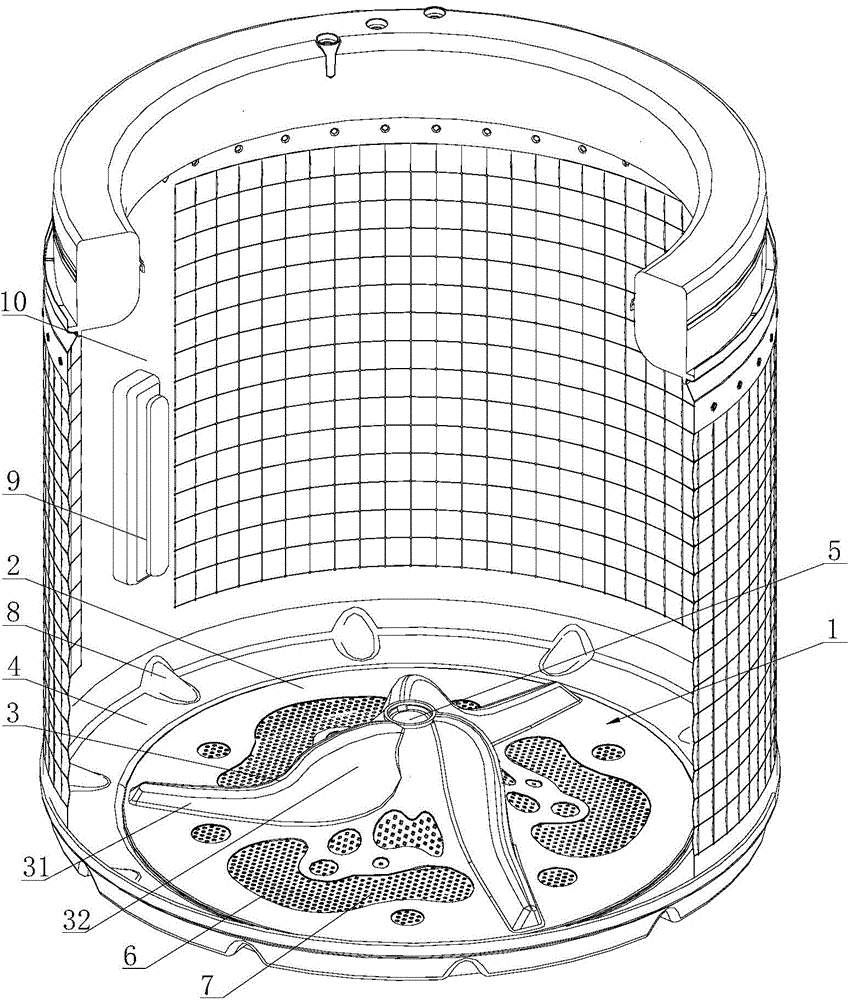

[0032]A washing machine described in this embodiment includes a washing tub and a pulsator 1 at the bottom of the washing tub. The pulsator 1 includes a wave plate 2 and a plurality of water-repelling leaves 3 arranged on the surface of the wave plate 2. The wave plate 2 It is a disc-shaped structure with a raised center, and each water-repelling leaf 3 extends from the raised center of the corrugated disc to the edge, and the inner wall 10 of the washing tub is provided with a plurality of vertical strip-shaped convex ribs 9 . The number of strip-shaped convex ribs is: 3-6, and a plurality of strip-shaped convex ribs are evenly arranged on the inner wall of the washing bucket. The ratio of the height of the strip-shaped convex ribs to the width of the outer ring of the bottom of the bucket is 1:2-1: 1, preferably 1:1.5. The strip-shaped rib 9 can drive the clothes in the washing tub to rotate at a small reverse angle relative to the pulsator 1. While the clothes are rotating,...

Embodiment 2

[0036] Such as figure 1 As shown, a washing machine described in this embodiment includes a washing tub and a pulsator 1 at the bottom of the washing tub. The pulsator 1 includes a wave plate 2 and a plurality of water-repelling leaves 3 arranged on the surface of the wave plate 2. The corrugated disc 2 is a disc-shaped structure with a raised center, and each water-repellent leaf 3 extends from the raised center of the corrugated disc to the edge, and the inner wall 10 of the washing tub is provided with a plurality of vertical strip-shaped ribs 9 . The number of strip-shaped convex ribs is: 3-6, and a plurality of strip-shaped convex ribs are evenly arranged on the inner wall of the washing bucket. The ratio of the height of the strip-shaped convex ribs to the width of the outer ring of the bottom of the bucket is 1:2-1: 1, preferably 1:1.5.

[0037] Simultaneously, there is a certain distance between the outer edge of the pulsator 1 and the bottom edge of the washing bucke...

Embodiment 3

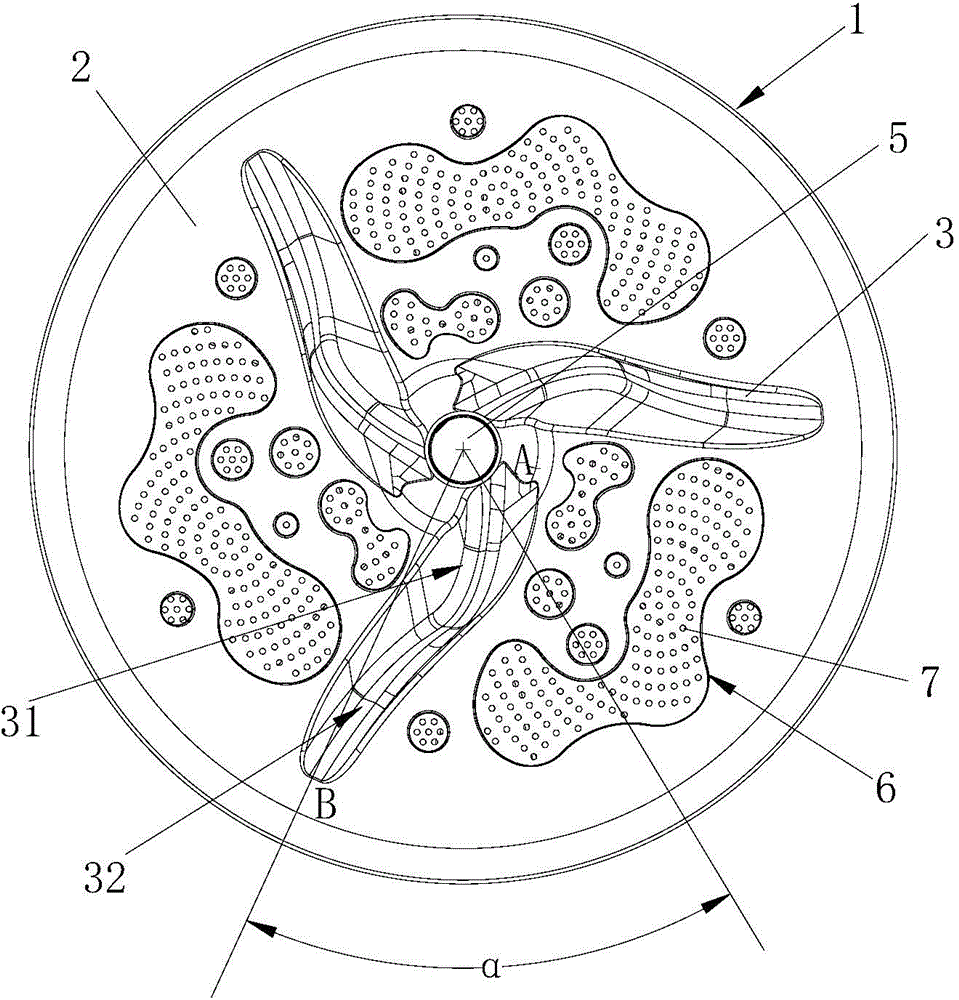

[0042] Such as figure 1 , figure 2 As shown, the water repellent blade 3 described in this embodiment includes a first section of convex rib 31 close to the center 5 of the wave plate and a second section of convex rib 32 close to the edge of the wave disk, the first section of convex rib 31 and the second section of convex rib The ribs 32 are inclined to the surface of the wave plate on different sides, and the inclination range of the first segment of the convex rib 31 is 5-10° relative to the vertical plane, which refers to the angle of the wave plate surface where the intersection line between the water-repelling blade and the wave plate surface is located. On the vertical plane, the direction of inclination is the clockwise rotation direction of the pulsator, and the inclination range of the second segment convex rib 32 relative to the vertical plane is 10-15°, and the inclination direction is the direction of counterclockwise rotation of the pulsator (refer to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com