Steam sterilizing method

A steam sterilization and steam technology, applied in food preservation, food science, heating, etc., can solve the problems of uneven preheating, incomplete preheating, soaking and dampness of the sterilization chamber, and achieve the guaranteed properties and quality, Prevent the material from getting wet and ensure the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

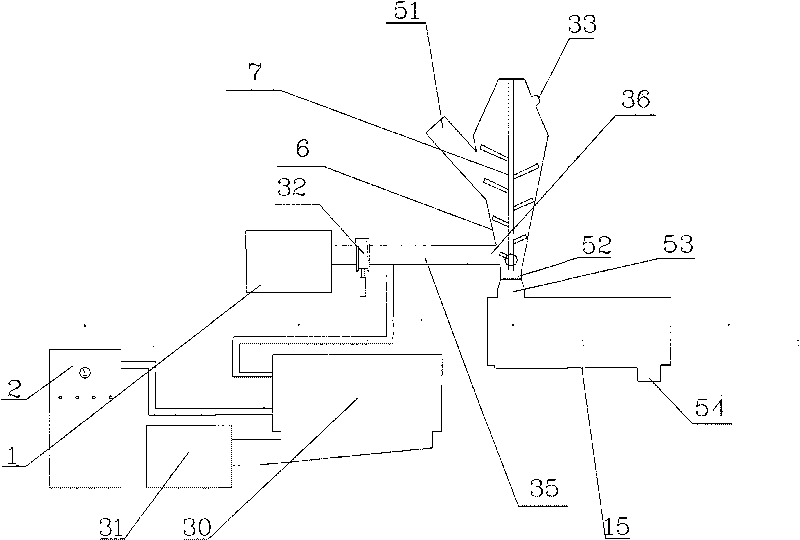

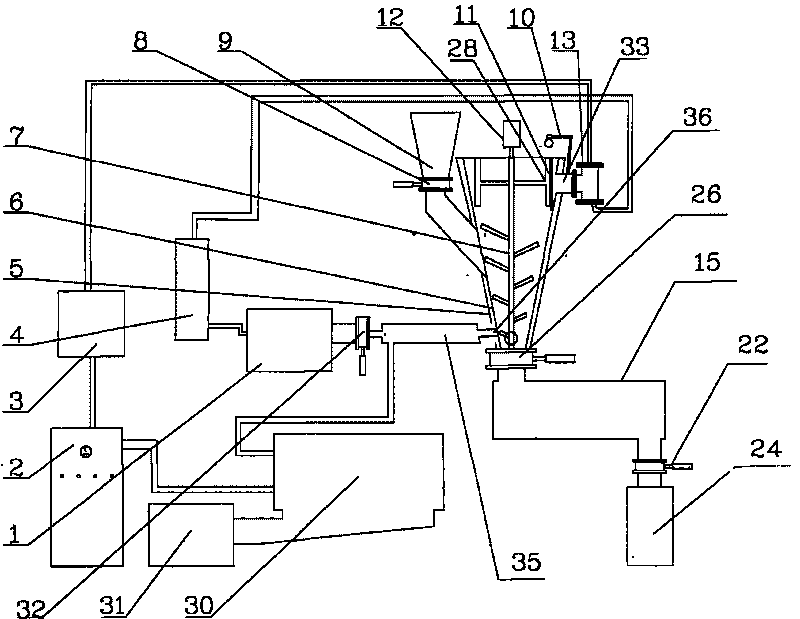

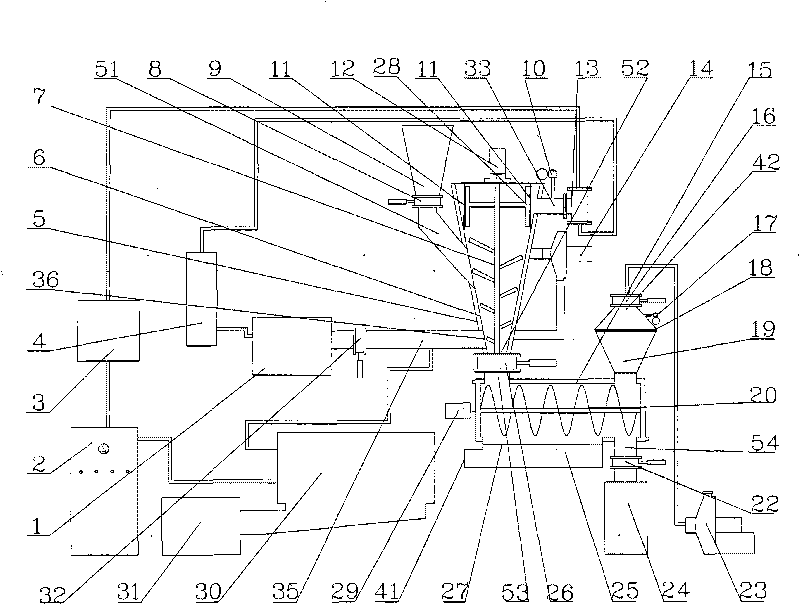

[0051] The steam sterilization method of the present invention, when the material to be sterilized is sterilized, it comprises the following steps:

[0052] (1) Open the gas discharge port 33 positioned at the top of the sterilization chamber 6, open the pneumatic valve 32 and the first hot air induced draft fan 1 that are successively connected to the hot air inlet 36 of the sterilization chamber 6, and utilize the first hot air induced The hot air provided by the fan 1 preheats the interior of the sterilization chamber 6; at the same time, open the second hot air induced draft fan 31 connected to the hot air inlet 36 of the sterilization chamber 6 through the energy storage type steam heat exchanger 30 , preheating the energy-storage steam heat exchanger 30;

[0053] The regulation on the preheating time of the sterilization chamber 6 must make the temperature of the preheated sterilization chamber 6 reach the set preheating temperature of about 120°C.

[0054] (2) When the...

Embodiment 2

[0065] The steam sterilization method of the present invention, when the material to be sterilized is sterilized, it comprises the following steps:

[0066](1) Open the gas discharge port 33 positioned at the top of the sterilization chamber 6, open the pneumatic valve 32 and the first hot air induced draft fan 1 that are successively connected to the hot air inlet 36 of the sterilization chamber 6, and utilize the first hot air induced The hot air provided by the fan 1 preheats the interior of the sterilization chamber 6; at the same time, open the second hot air induced draft fan 31 connected to the hot air inlet 36 of the sterilization chamber 6 through the energy storage type steam heat exchanger 30 , preheating the energy-storage steam heat exchanger 30;

[0067] The regulation on the preheating time of the sterilization chamber 6 must make the temperature of the preheated sterilization chamber 6 reach the set preheating temperature of about 130°C.

[0068] (2) When the ...

Embodiment 3

[0080] The steam sterilization method of the present invention, when the material to be sterilized is sterilized, it comprises the following steps:

[0081] (1) Open the gas discharge port 33 positioned at the top of the sterilization chamber 6, open the pneumatic valve 32 and the first hot air induced draft fan 1 that are successively connected to the hot air inlet 36 of the sterilization chamber 6, and utilize the first hot air induced The hot air provided by the fan 1 preheats the interior of the sterilization chamber 6; at the same time, open the second hot air induced draft fan 31 connected to the hot air inlet 36 of the sterilization chamber 6 through the energy storage type steam heat exchanger 30 , preheating the energy-storage steam heat exchanger 30;

[0082] The regulation on the preheating time of the sterilization chamber 6 must make the temperature of the preheated sterilization chamber 6 reach the set preheating temperature of about 130°C.

[0083] (2) When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com