Wax liquid conveying and recycling system

A recovery system and wax liquid technology, which is applied in the direction of transportation packaging, transportation and packaging, and devices for coating liquid on the surface, can solve the problems of inability to ensure sealing, high failure rate, and shortened validity period, so as to improve product qualification High efficiency, high degree of automation, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

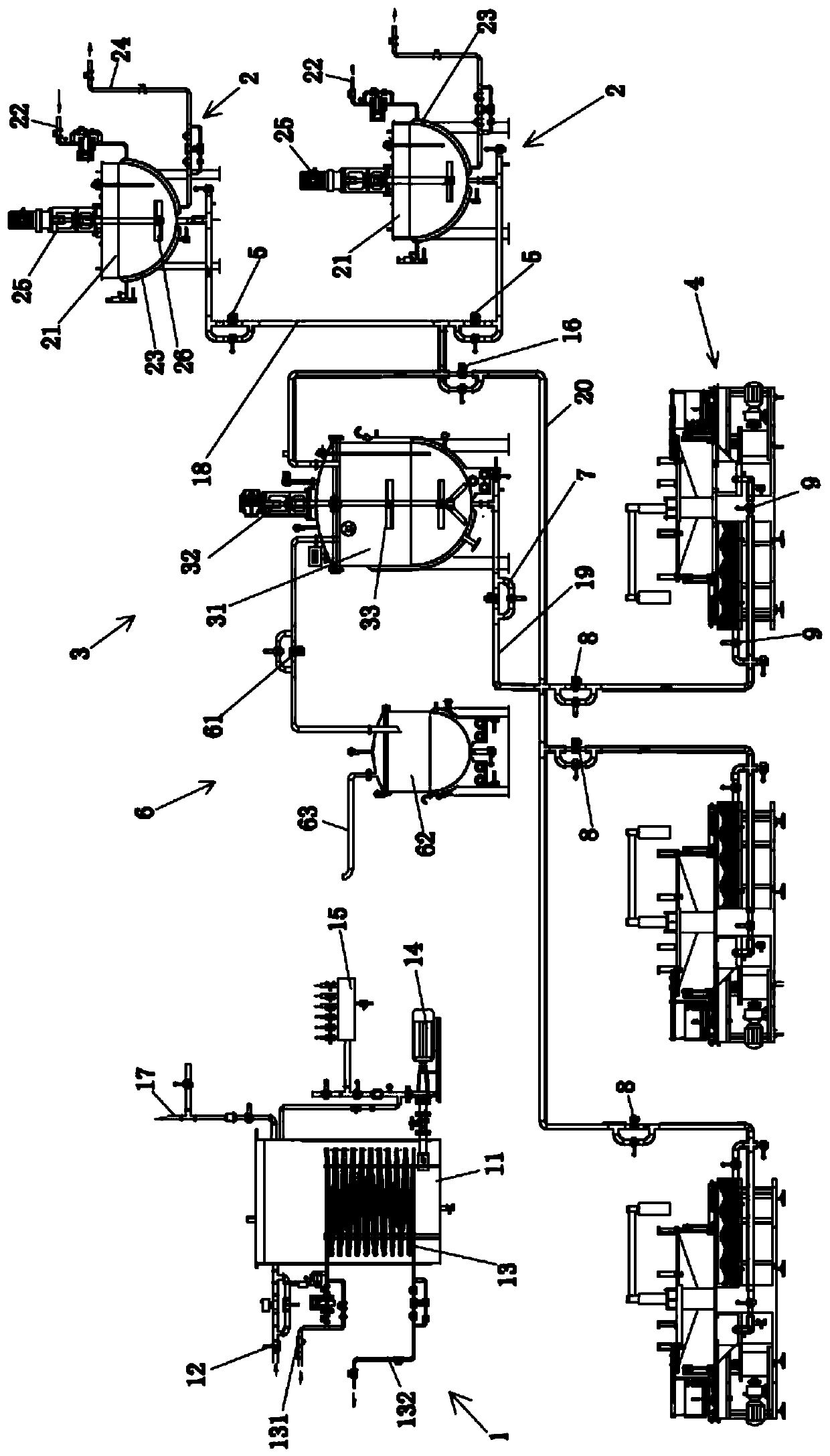

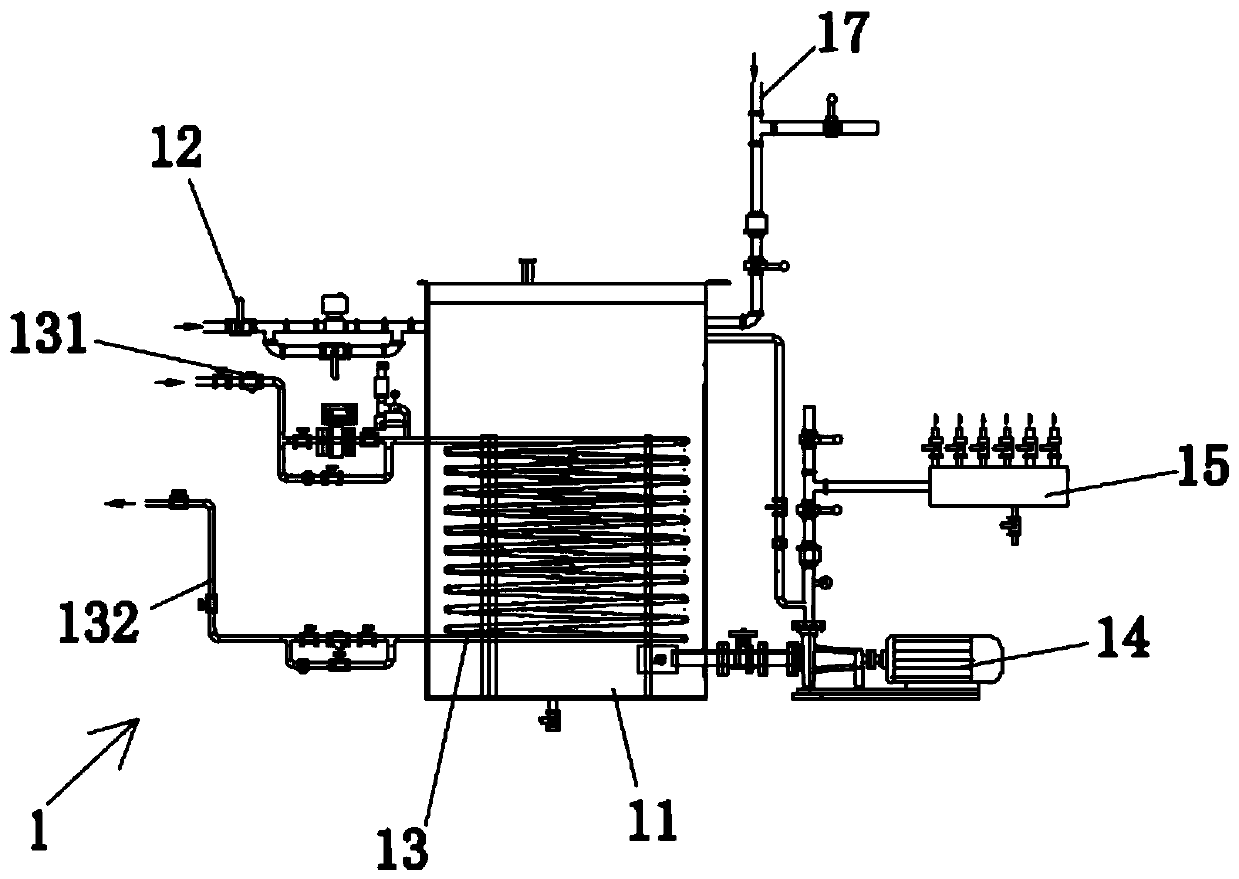

[0030] The specific embodiment of the present invention is as figure 1 with figure 2 As shown, a wax delivery and recovery system includes a heating and stirring device 2 , a first wax delivery pipe 18 , a heat preservation and stirring device 3 and a second wax delivery pipe 19 sequentially connected along the wax delivery direction. Both the first wax delivery pipe 18 and the second wax delivery pipe 19 are provided with a first heat preservation structure.

[0031] The wax liquid delivery and recovery system also includes a hot water machine 1 . The first heat preservation structure on the first wax delivery pipe 18 and the second wax delivery pipe 19 is a hot water chamber, and the water outlet of the water heater 1 communicates with the hot water chambers of the first wax delivery pipe 18 and the second wax delivery pipe 19 .

[0032] The heat preservation and stirring device 3 is connected with a vacuum wax extraction device 6 . The vacuum wax extraction device 6 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com