Fuel gas hot blast stove

A technology of gas-fired hot blast stove and hot blast stove, which is applied in the direction of air heater, fluid heater, dry gas arrangement, etc., and can solve problems such as output rate, low production volume, and variability of plasterboard, and achieve improvement The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

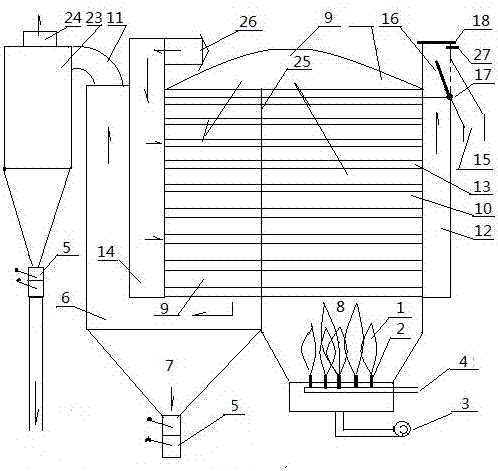

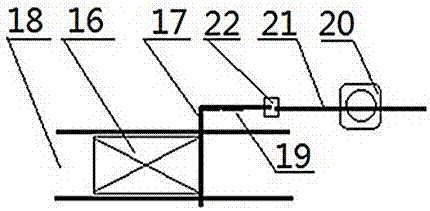

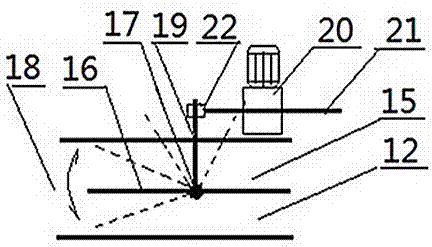

[0047] A hot blast stove, comprising: gas flame 1, gas nozzle 2, blower 3, gas pipe 4, double relay valve 5, return air pipe 6, ash bucket 7 under the return air chamber of the hot blast stove, combustion chamber 8 of the hot blast stove, Hot blast stove return air chamber 9, hot air main air chamber 10, air outlet pipe 11, secondary hot air passage outlet chamber 12, hot air exchange pipe 13, secondary hot air passage inlet chamber 14, cold air pipe 15, adjustable damper 16, Damper shaft 17, secondary hot air exhaust port 18, damper shaft crank arm 19, electric screw motor 20, electric screw rod 21, connector 22, dust collector 23, dust collector exhaust pipe 24, middle partition 25, air filter 26 , temperature sensor 27.

[0048] It is characterized in that: several gas nozzles 2 are arranged in the combustion chamber 8 of the hot blast stov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com