Full-biodegradation mulch film for rice planting and production method thereof

A technology of degrading plastic film and whole biology, applied in the field of full biodegradable plastic film for rice planting, can solve the problems of polluted environment and difficult recycling of ordinary plastic film, reduce the harm of weeds and diseases and insect pests in the field, save the cost of artificial weeding, and produce rice. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 The preparation of fully biodegradable mulch film for rice planting

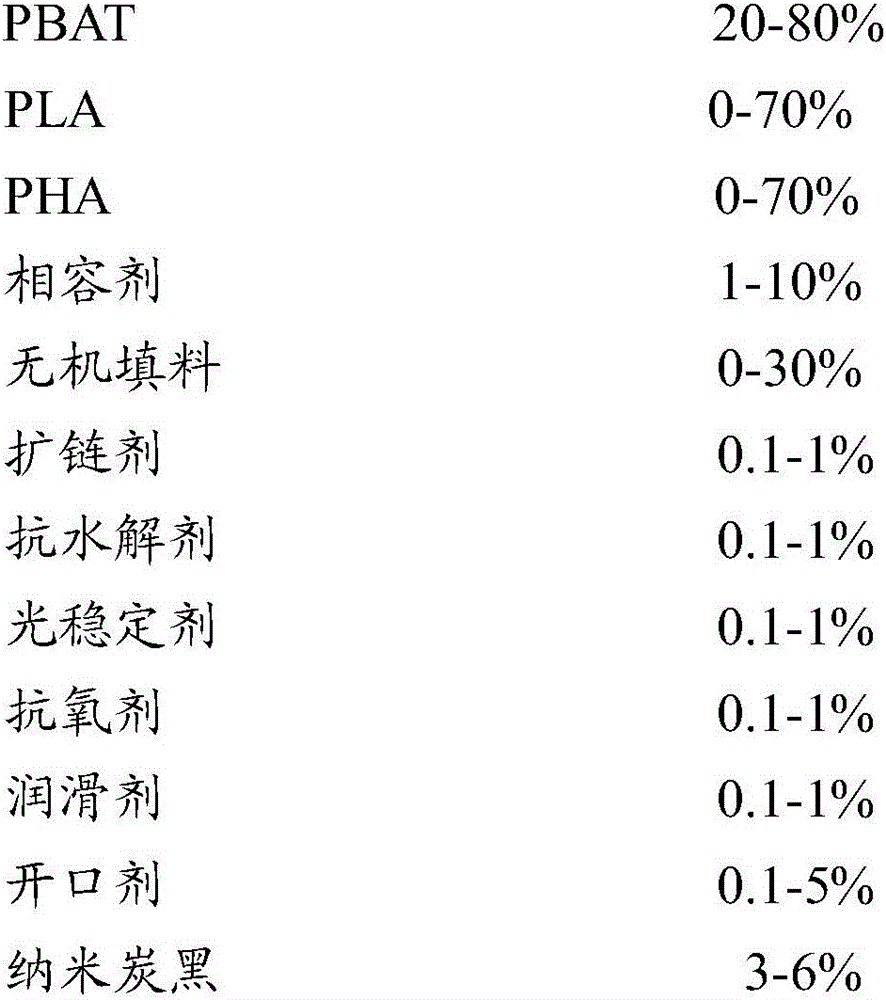

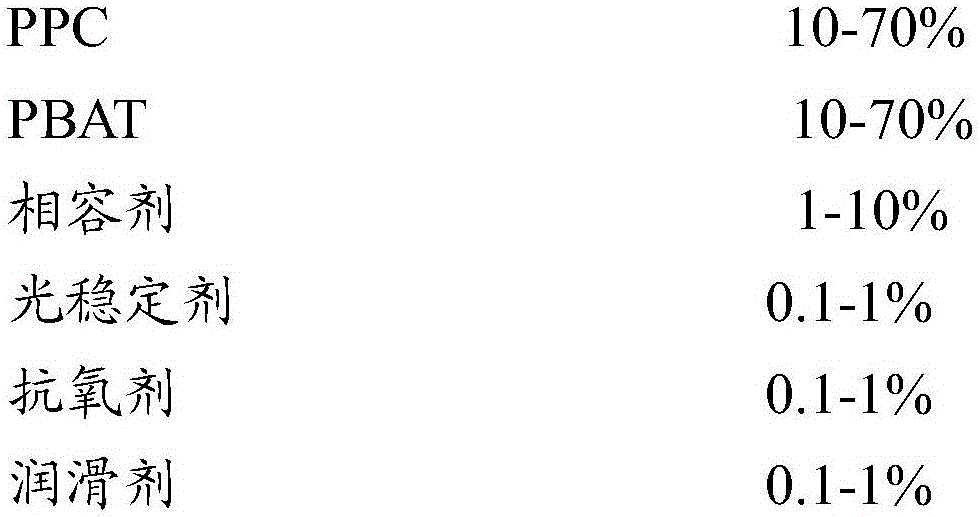

[0041] In this example, through the three-layer co-extrusion technology, the surface layer PBAT, PLA, PHA are blended and modified; the middle layer PPC, PBAT multi-layer composite realizes low film thickness and high elongation at break, and the thickness ratio of the three layers is 1:1:1. And by adding compatibilizers, chain extenders, anti-hydrolysis agents, light stabilizers, antioxidants, etc. to improve its degradation performance; adding modified talcum powder, lubricants, anti-blocking agents to improve processing performance, improve the first pass rate, increase Film toughness and reduced cost. The invention prepares a functionally reliable and cost-acceptable fully degradable mulch film suitable for rice by reducing thickness, increasing added value through functionalization, and improving process stability. The formulations of each layer are counted by weight. Among them, PB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com