Cold polishing technique of rice finish machining

A rice and process technology, applied in application, grain processing, agriculture, etc., can solve the problems of damaging the internal physical properties of rice grains, affecting the rice yield coefficient of rice quality, and unsatisfactory effects, and reducing labor workload and broken rice rate. The effect of reducing and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only used as examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

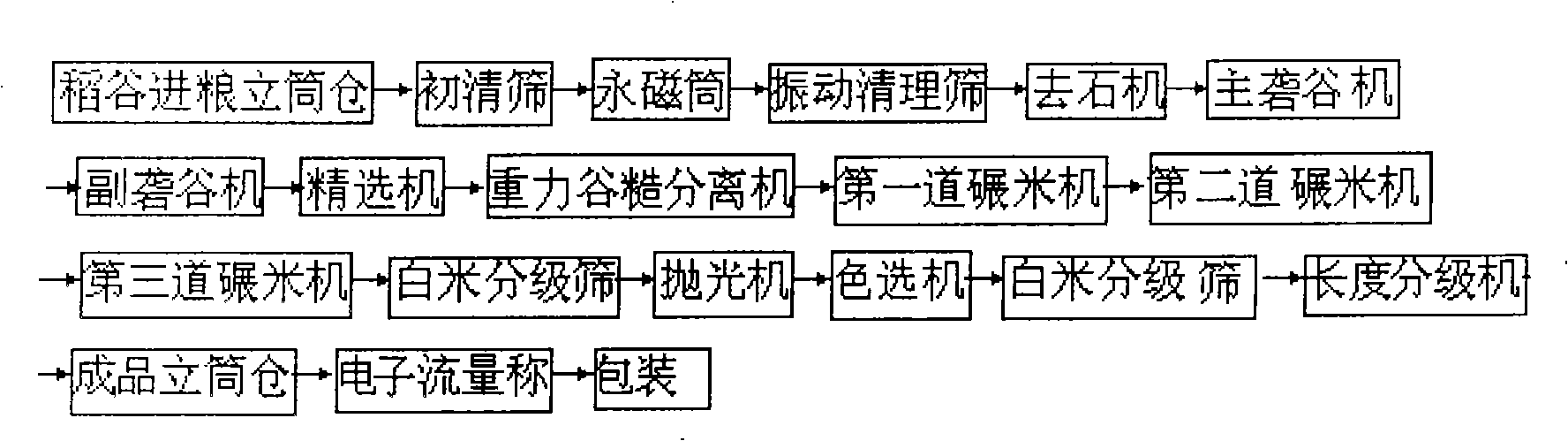

[0012] Referring to the accompanying drawings, it can be seen that the cold polishing process for rice finishing of the present invention comprises a vertical silo for rice feeding → initial cleaning (effect of removing impurities) → permanent magnetic cylinder (effect of removing iron) → vibrating cleaning screen (effect of removing sand) Function)→Stoning machine (removing stones)→Husher (husker function)→Selection machine (function of selecting grains)→Gravity paddy separator (removing empty paddy husk)→The first mill Rice machine → second rice mill → third rice mill → white rice grading sieve (grading rice) → polishing machine (increasing the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com