Device and method for recycling wall plastering materials for building construction

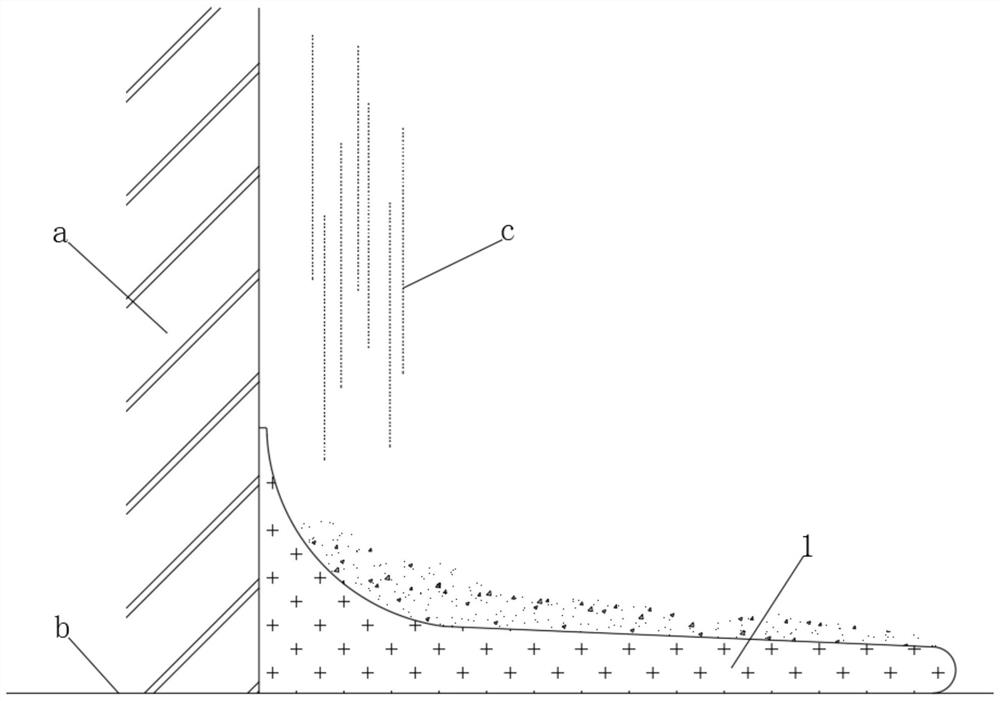

A material recovery and recycling method technology, applied in construction, building structure and other directions, can solve the problems of low recovery efficiency, great difficulty in crushing, and large block diameter of plastering materials, so as to avoid low oil uniformity and avoid The effect of increasing the difficulty of recycling and reducing the difficulty of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

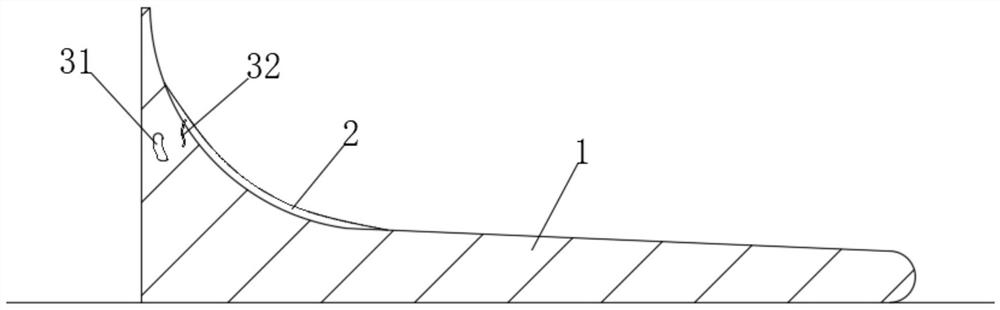

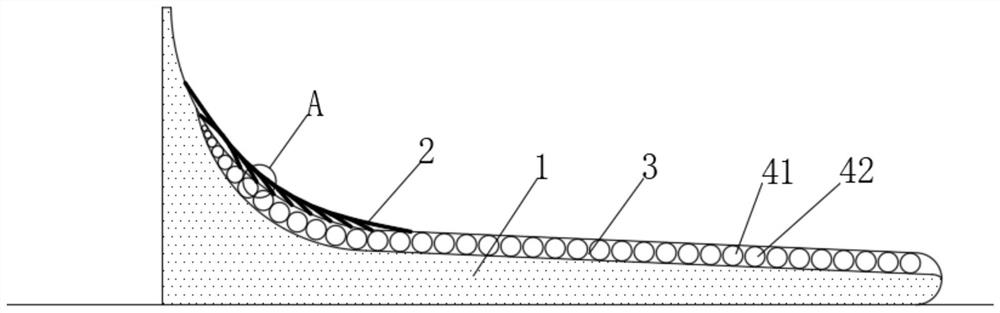

[0046] see Figure 2-3 , a kind of wall painting material recovery device for building construction, comprising a device body 1, the outer end of the device body 1 is fixedly connected with a ventilation pipe 31, the ventilation pipe 31 communicates with the inside of the device body 1, and the upper end of the device body 1 is fixedly connected with a self-heaving Loose layer 3, the interior of the self-undulating loose layer 3 is inlaid with a plurality of evenly distributed self-expanding dynamic balls 41 and shaped dynamic balls 42, a plurality of self-expanding dynamic balls 41 and shaped dynamic balls 42 are alternately distributed, and the upper left end of the self-rising loose layer 3 A self-lubricating patch 2 is attached to the corner, and the outer end of the self-lubricating patch 2 is fixedly connected with an oil passage 32, which communicates with the interior of the self-lubricating patch 2, and the interior of the self-lubricating patch 2 is filled with lubric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com