Fully-automatic numerical control composite inner surface grinding machine

An inner surface, fully automatic technology, applied in the direction of grinding machines, grinding machine parts, grinding feed movement, etc., can solve the problems of low degree of automation, achieve ingenious structure design, high efficiency of inner surface processing, and simple control program Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

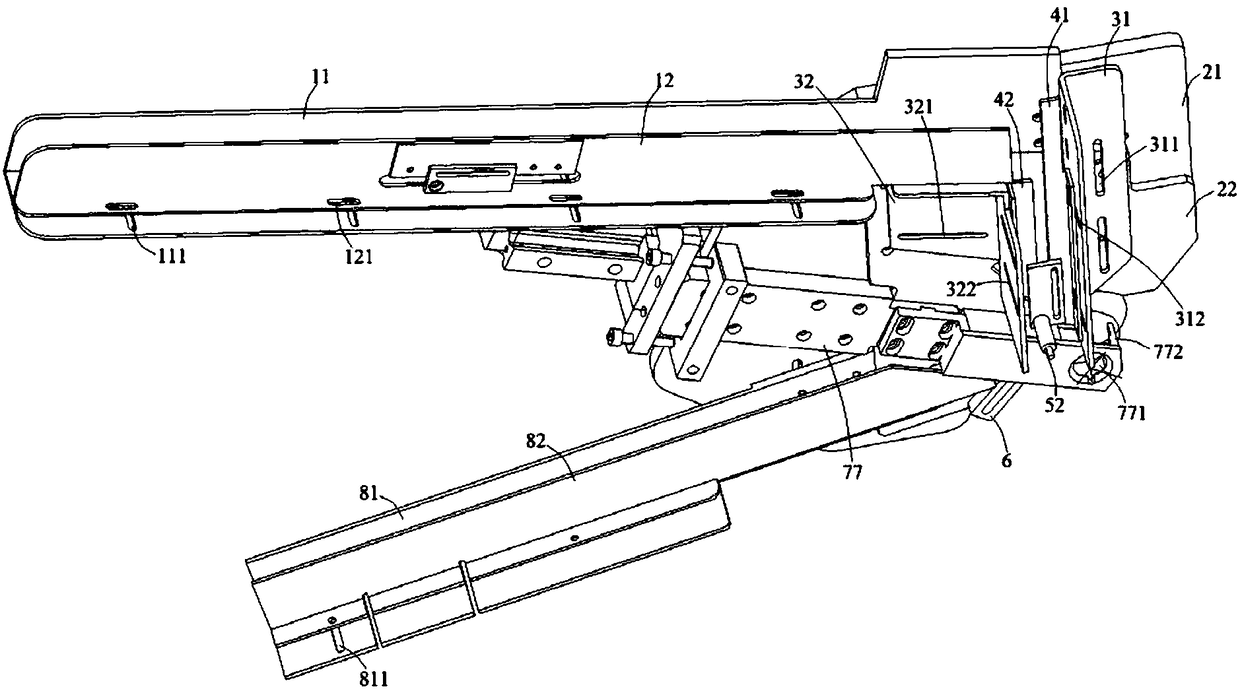

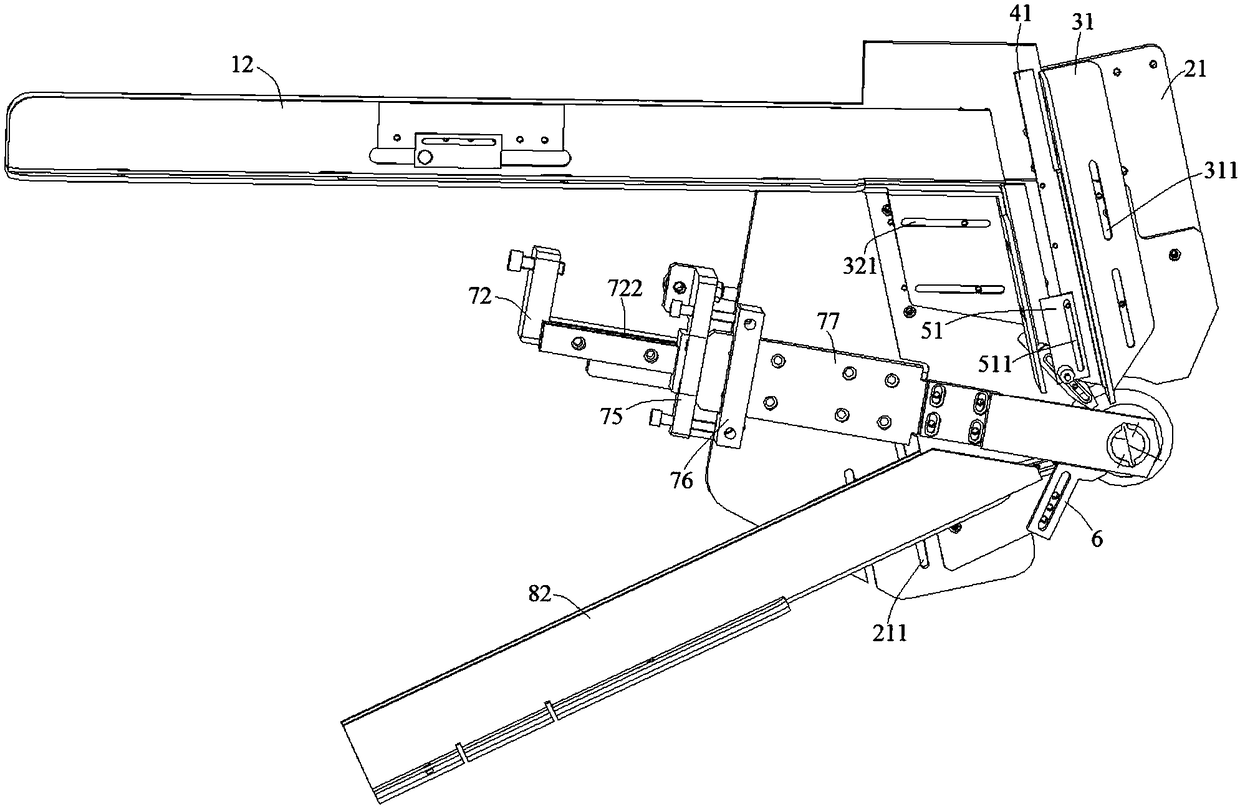

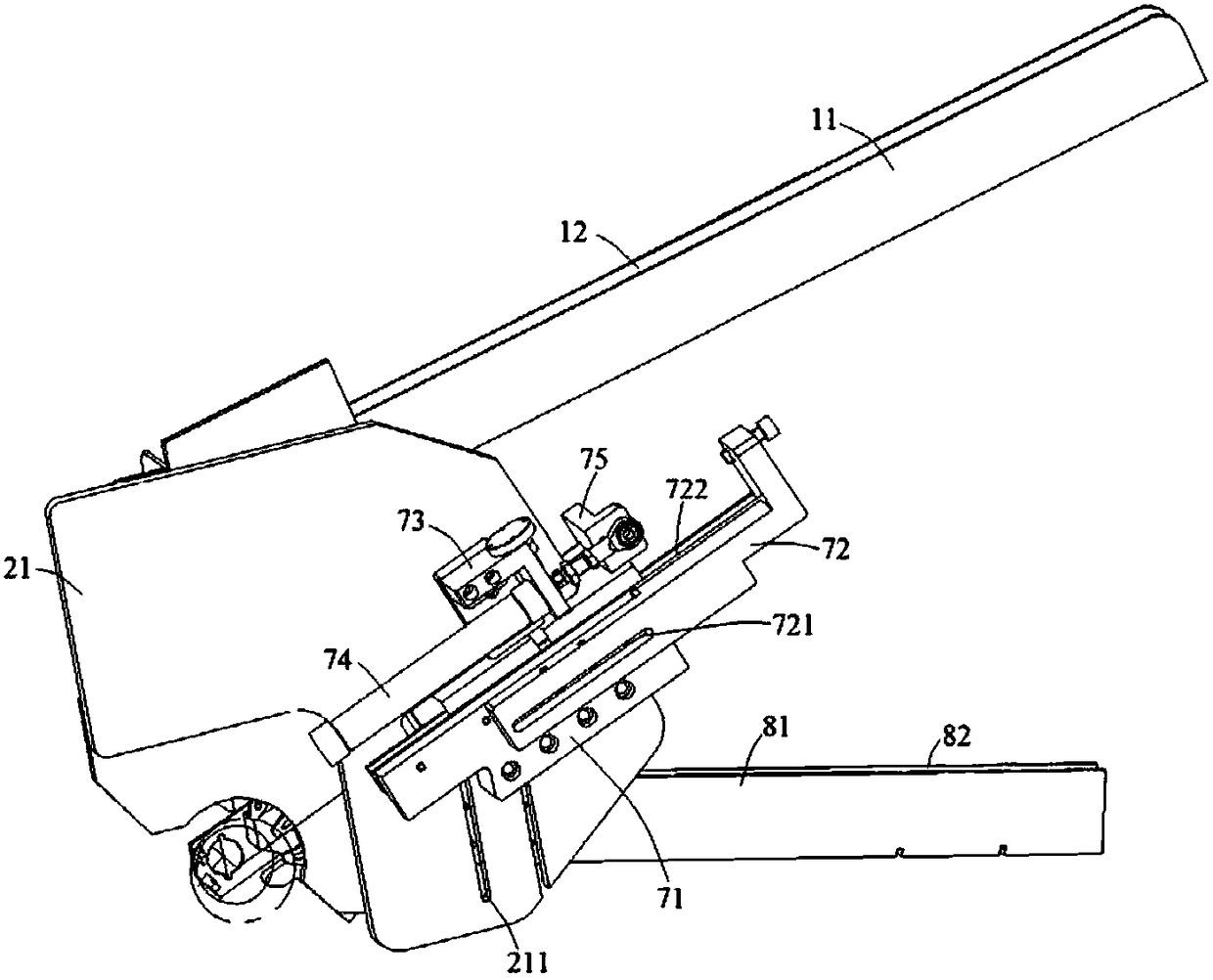

[0033] Referring to the accompanying drawings, a fully automatic numerically controlled compound internal surface grinding machine of this embodiment includes a bed body 10, a servo drive mechanism and a workpiece conveying mechanism. Among them, see Figure 4, The servo drive mechanism of this embodiment includes a grinding wheel feeding motor 91, a grinding wheel driving spindle 92, a workpiece feeding motor 93, a carriage 94, a magnetic chuck 95, a grinding wheel and a grinding wheel dresser. The grinding wheel feeding motor 91 is arranged on one side of the bed body 10 in the longitudinal direction, and the grinding wheel feeding motor 91 drives a carriage to reciprocate along the length direction of the bed body 10 . A grinding wheel driving spindle 92 is arranged on the carriage, and the grinding wheel driving spindle 92 is connected with a grinding wheel to control the rotation of the grinding wheel to grind the workpiece 98 . A workpiece feed motor 93 is arranged on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com