Variable adjustment interval whole-plant AVC-unit reactive power combined control method and system

A joint control and plant-wide technology, applied in reactive power compensation, AC network voltage adjustment, single network parallel feeding arrangement, etc., can solve the problems of lack of reactive power adjustment technology, irregular load adjustment, low commissioning rate, etc. , to achieve reasonable performance of the unit, improve the level of safety and stability, and solve the effect of low operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The whole plant AVC-unit reactive power joint optimal control method of the variable adjustment interval of the present invention, a kind of technical scheme during concrete implementation is as follows:

[0035] A variable adjustment interval whole plant AVC-unit reactive power joint control method, comprising the following steps:

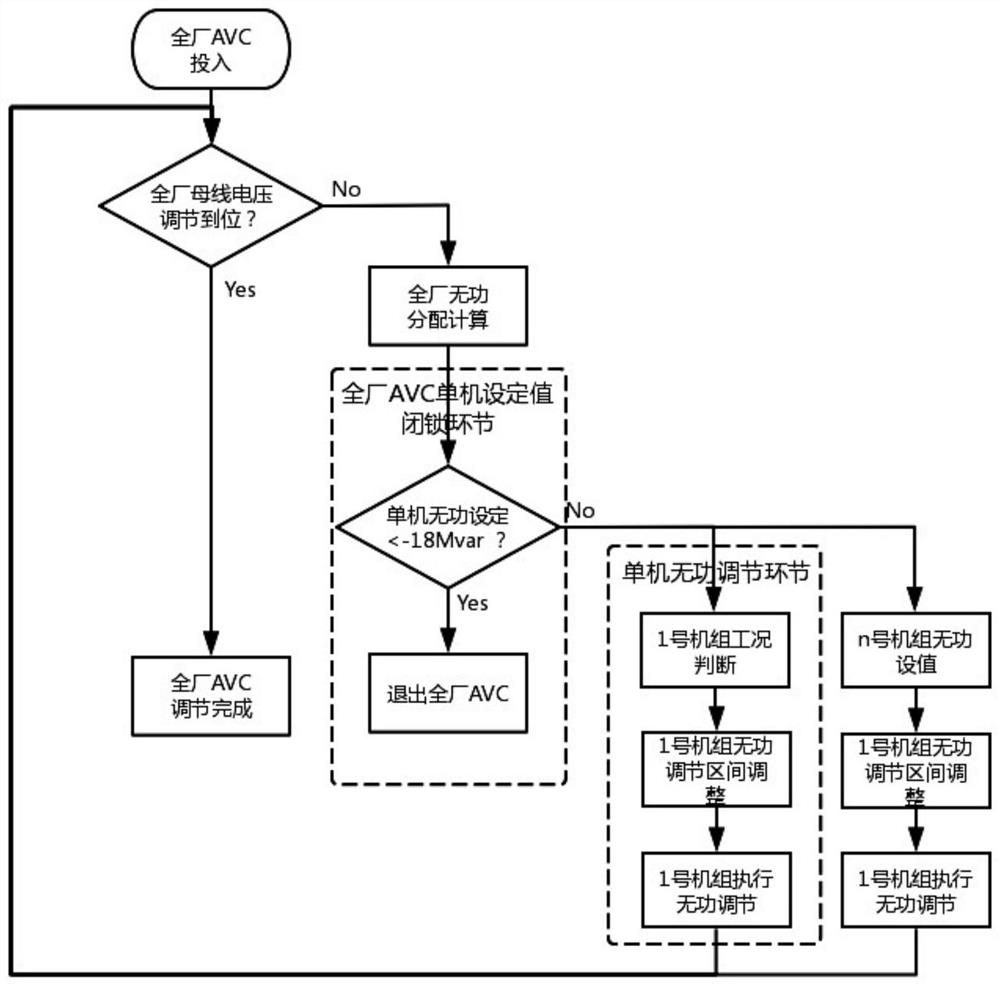

[0036] (1) Judgment of bus voltage and reactive power distribution of the whole plant

[0037] like figure 1 As shown, when the AVC function of the whole plant is put into use, the AVC adjustment of the whole plant will start immediately, and the actual value of the bus voltage and the adjustment target value of the whole plant will be monitored and judged, and based on the internal logic and algorithm of AVC (equal distribution, equal offset, Equal power factor, etc., depending on the situation of each plant station) to calculate the reactive power distribution of the whole plant, and obtain the set value of reactive power of each unit, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com