Patents

Literature

67results about How to "Operational Coordination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

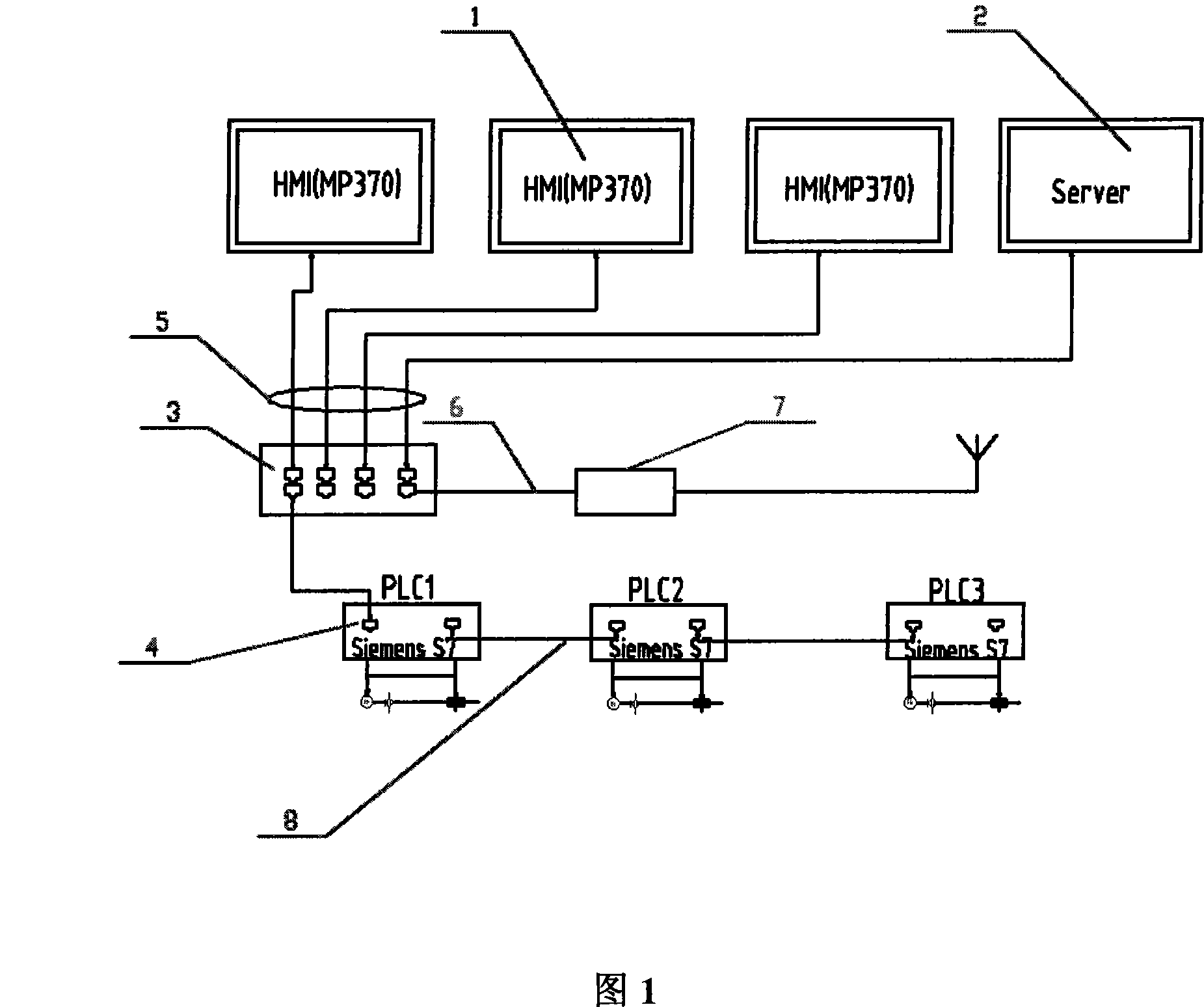

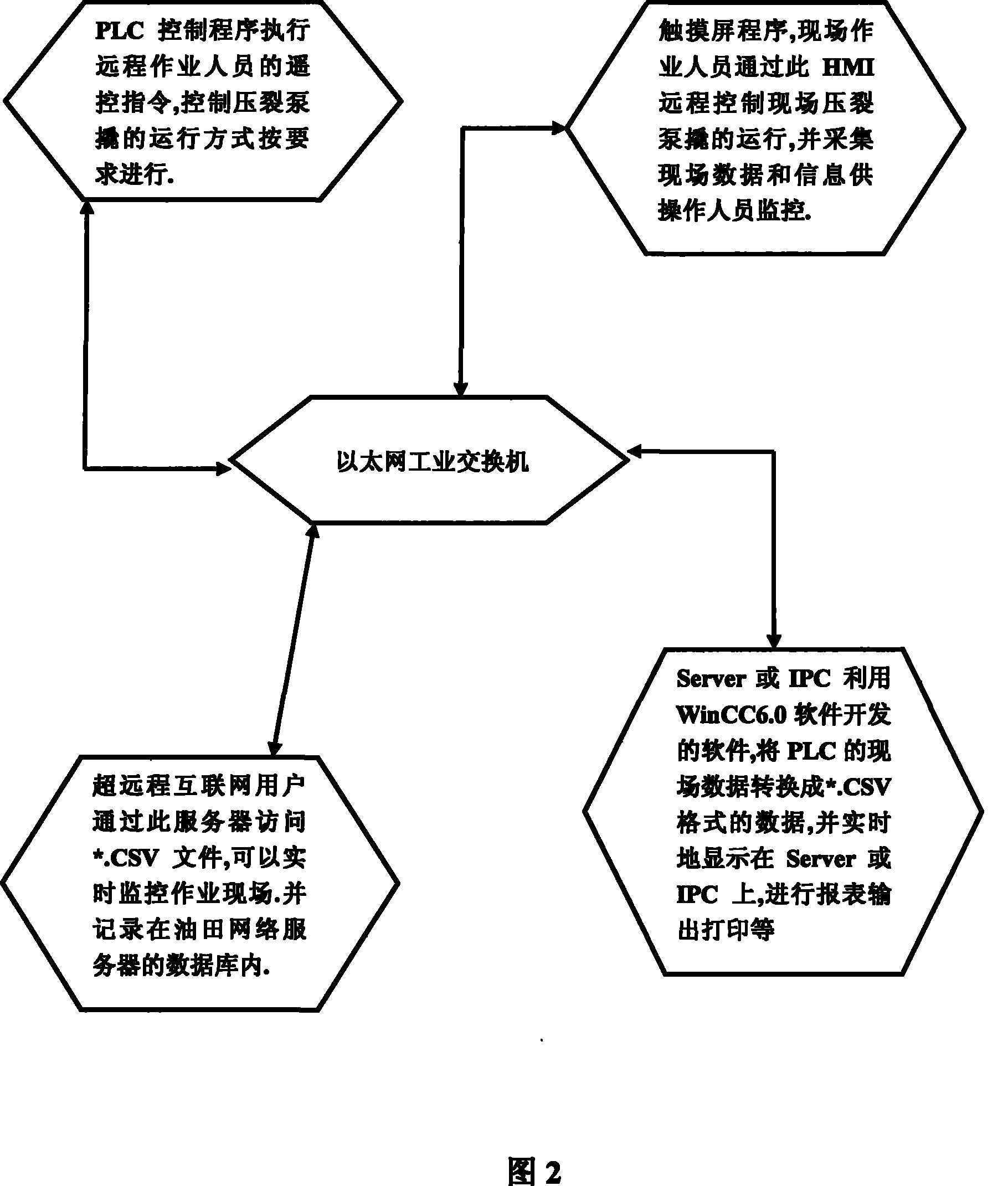

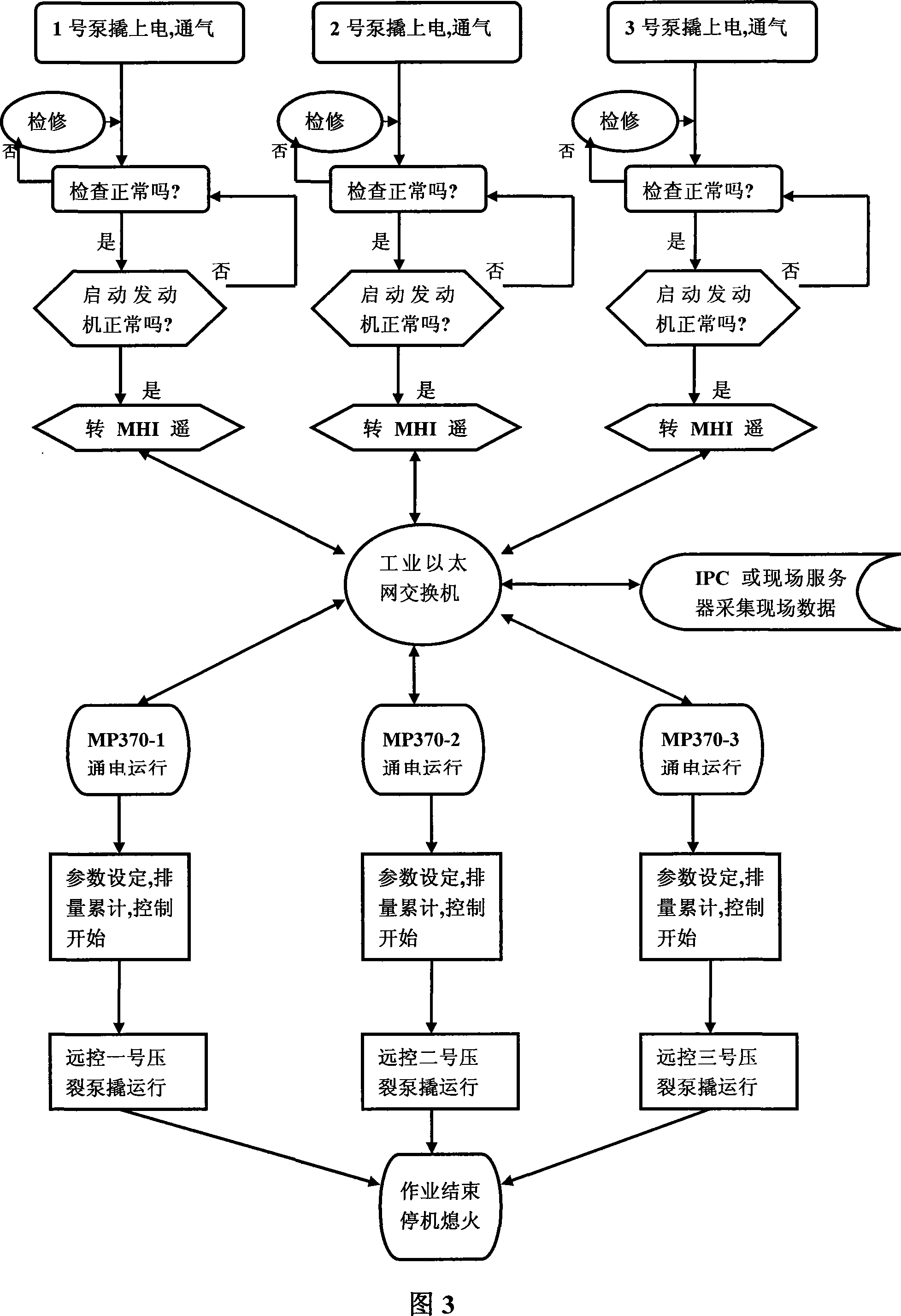

Remote, automatic control system for oil field fracturing pumping

ActiveCN101414171BMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

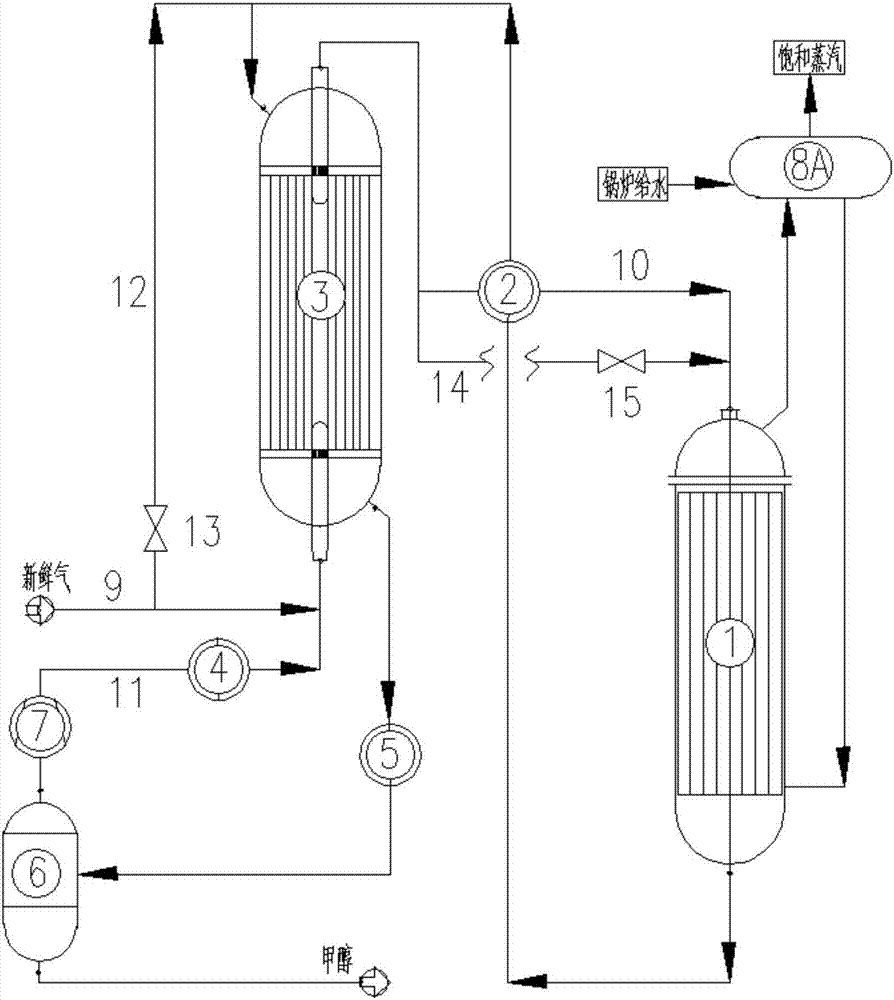

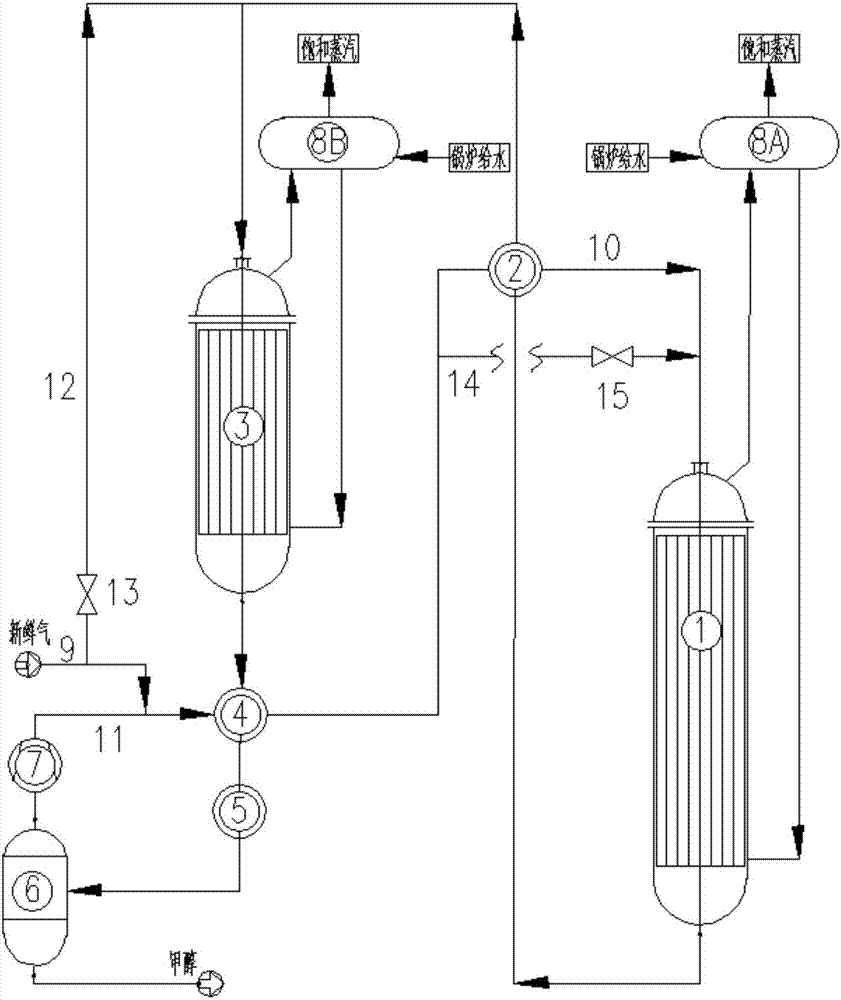

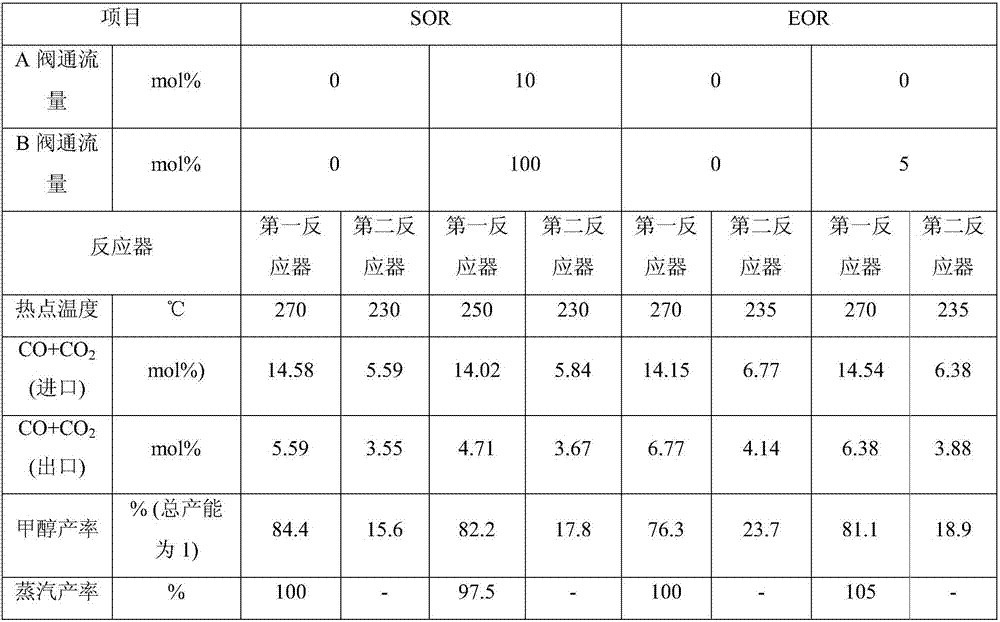

Technology and device forsynthesizingmethanol

ActiveCN107382665AIncrease profitGood synchronization of service lifeOrganic compound preparationHydroxy compound preparationSyngasMixed gas

The invention discloses a technology for synthesizing methanol. The technology comprises the following steps: generating methanol by a methanol synthesis gas containing fresh gas through a first reactor; exchanging the heat of the mixed gas containing the synthesis gas and methanol steam with the heat of the synthesis gas containing fresh gas to be fed into the first reactor and then generating methanol through a second reactor; cooling the synthesis gas in higher methanol concentration after the reaction, and then guiding into a methanol separator and separating methanol; mixing the synthesis gas after separating methanol with fresh gas, thereby acquiring the synthesis gas containing fresh gas; guiding the synthesis gas containing fresh gas into the first reactor again; utilizing a valve A to directly guide a part of fresh gas into the second reactor and controlling the hot-spot temperature of a catalyst bed of the second reactor within 250 DEG C; keeping a part of synthesis gas containing fresh gas free from heat exchange and directly introducing into the first reactor by a valve B; controlling the gas inlet temperature of the second reactor at 200-240 DEG C. According to the invention, the use ratio of the catalyst is increased, the quality of the methanol product is improved and the running stability of the production device is improved.

Owner:NANJING GOODCHINA CHEM TECH

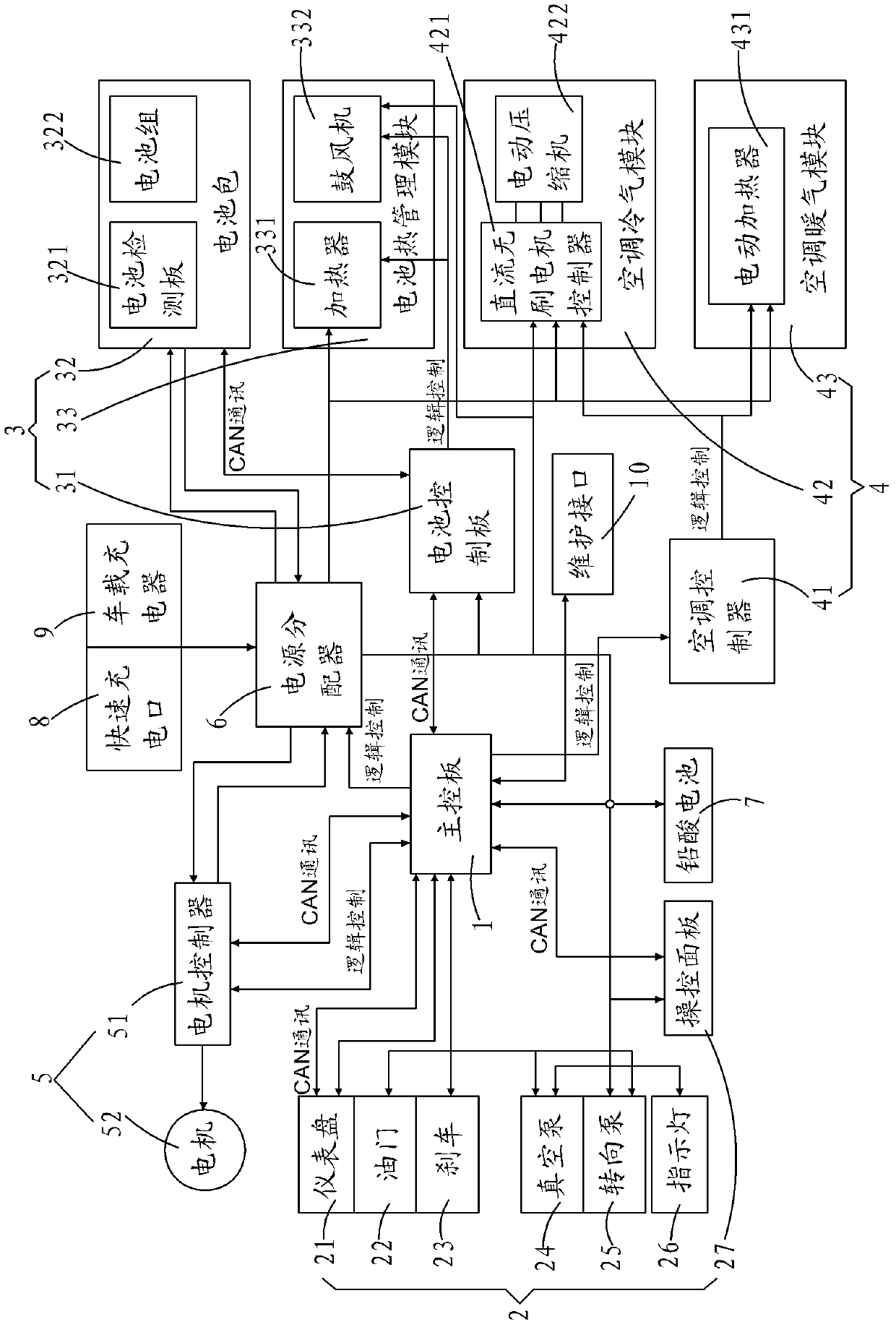

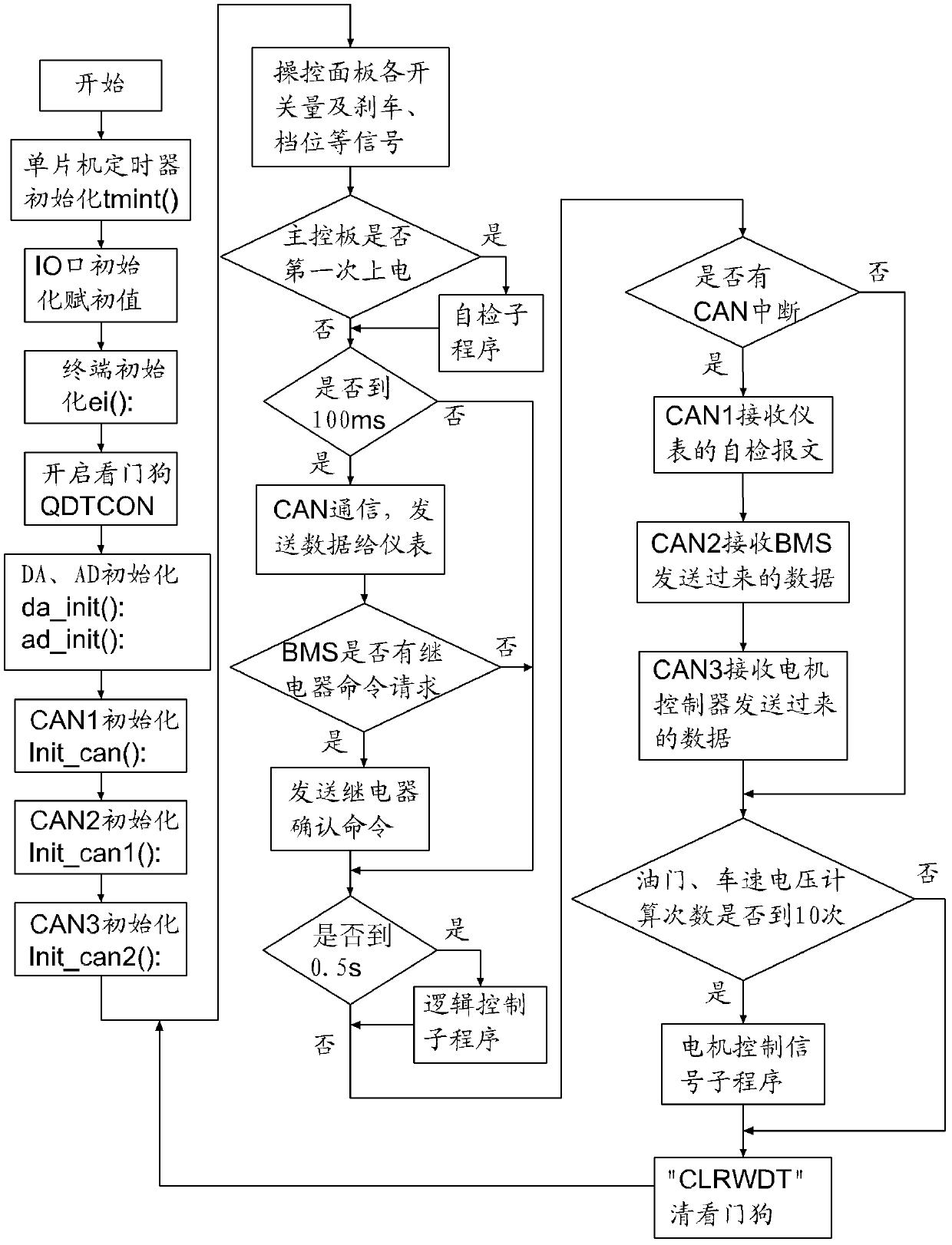

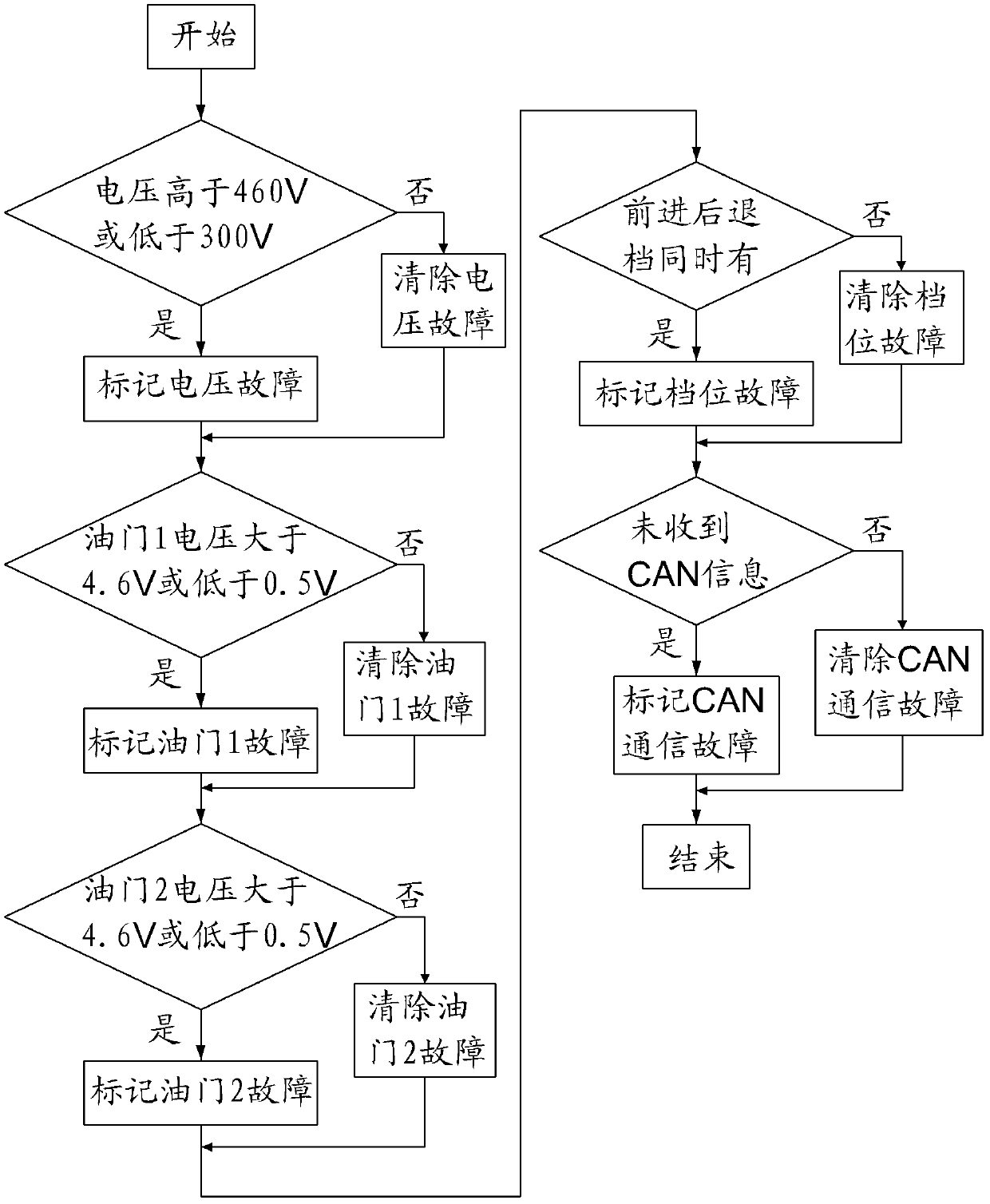

Whole automobile control system for electric automobile

InactiveCN102381266ARealize vehicle control requirementsOperational CoordinationElectric/fluid circuitElectric machineryAutomotive engineering

The invention provides a whole automobile control system for an electric automobile, which comprises a main control board, a control assembly, a battery assembly, an air conditioning assembly and a motor assembly, wherein the control assembly, the battery assembly, the air conditioning assembly and the motor assembly are connected with the main control board, the control assembly comprises an instrument panel, an accelerator, a brake, a vacuum pump, a steering pump, an indicating lamp and an operation control panel which are respectively connected with the main control board, the battery assembly comprises a battery control board, a battery pack and a battery heat management module, the battery control board is connected with the main control board, the battery pack and the battery heat management module are connected with the battery control board, the battery pack comprises a battery detection board and a battery group, the battery heat management module comprises a heater and a blast blower, the air conditioning assembly comprises an air conditioning controller, an air conditioning cold air module and an air conditioning hot air module, the air conditioning cold air module and the air conditioning hot air module are connected with the air conditioning controller, and the motor assembly comprises a motor controller and a motor, the motor controller is connected with the main control board, and the motor is connected with the motor controller. The whole automobile control system can meet the control requirement of the whole system of the electric automobile.

Owner:SOUEAST

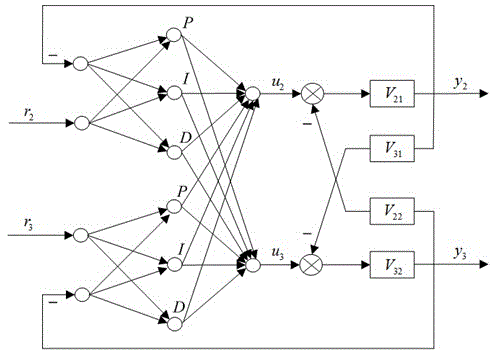

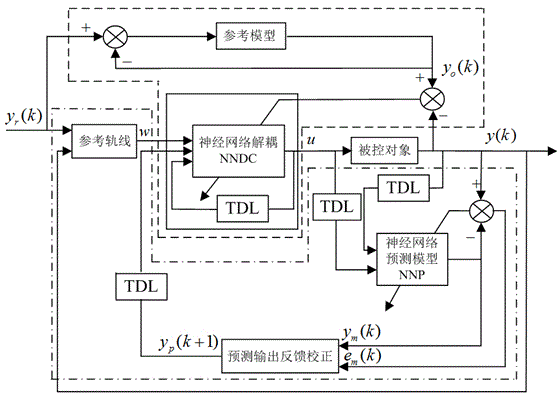

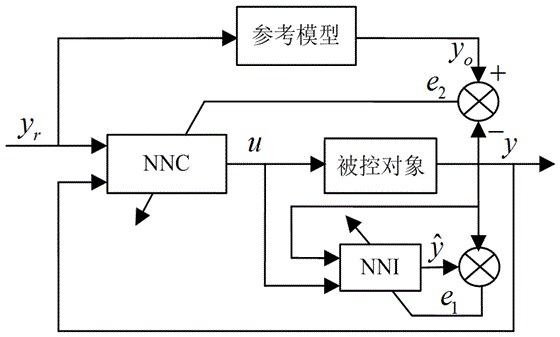

Decoupling control method of single leg joint of hydraulic four-leg robot

The invention discloses a decoupling control method of a single leg joint of a hydraulic four-leg robot. The method comprises proportion integration differentiation (PID) neural network decoupling control, neural network model reference decoupling control and prediction control. The method comprises the following steps that a reference model under the condition that a system is free of coupling is set, and then a neural network controller is trained so that the output of the system can keep up with the output of the reference model; meanwhile, a neural network model is used for prediction, and the next step of output of the system is predicted according to current and previous input and output data of a controlled object; and finally, the weight of the neural network is rectified in an online mode according to the predicted output and the given reference output so that optimizing indexes of the decoupling controller of the neural network can reach the smallest value, and the purpose of decoupling control is achieved. By the adoption of the decoupling control method, the coupling influences among all the joints of the robot can be effectively reduced, and decoupling control over all the joints of the robot is achieved.

Owner:HARBIN UNIV OF SCI & TECH

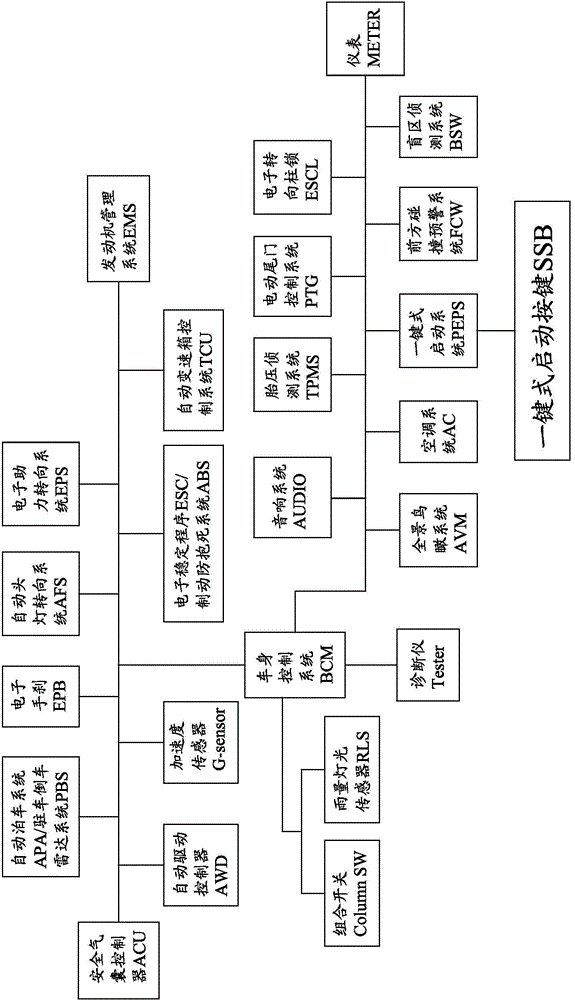

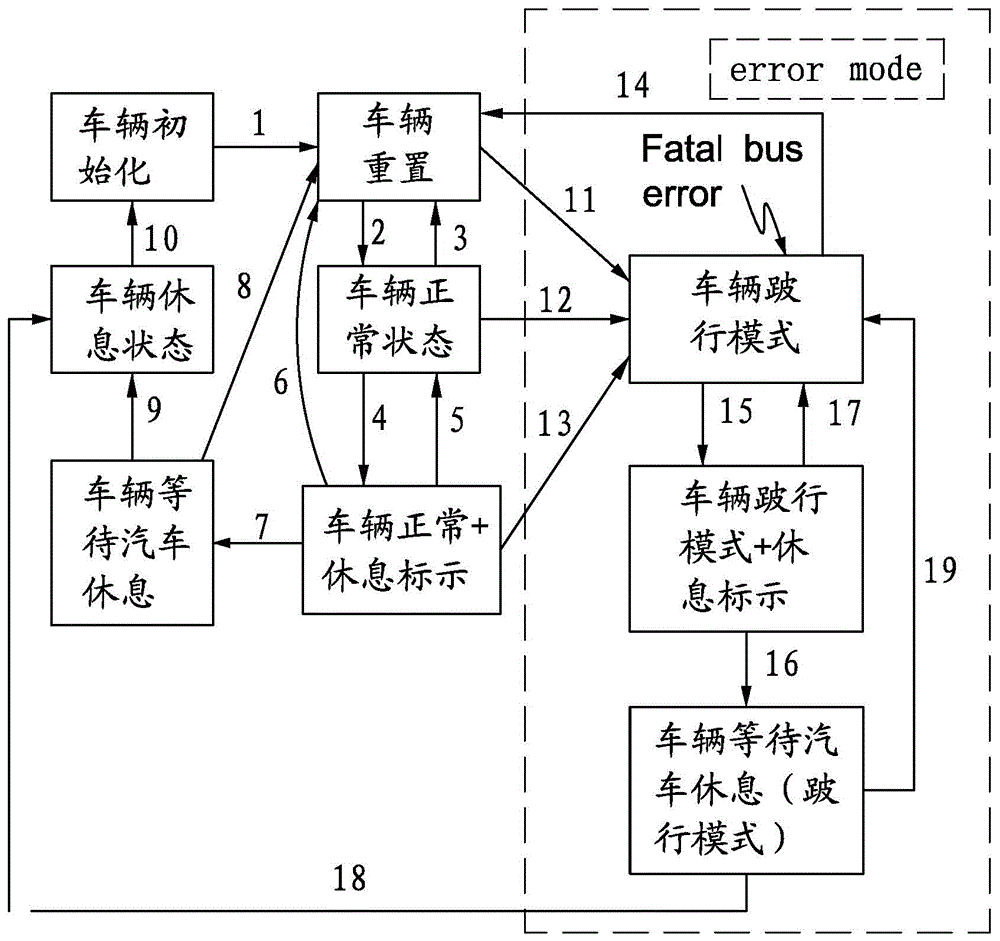

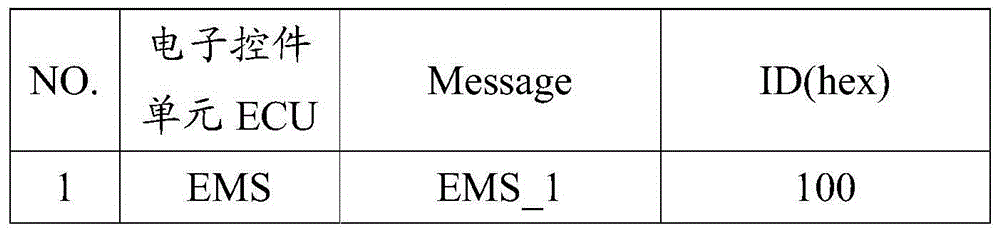

Overall vehicle bus control system

The invention provides an overall vehicle bus control system. The overall vehicle bus control system comprises a power CAN network, a vehicle body CAN network, a diagnosis CAN network, a BCM LIN network and a PEPS LIN network. By the adoption of the CAN / LIN bus system and the adoption of two network management methods and the unified diagnostic criteria in three CAN bus systems and two LIN bus systems, the overall vehicle cost can be reduced effectively, wire harness resources can be saved effectively, information transfer and resource sharing among nodes of all the buses can be realized, operation of power units and operation of vehicle body units can be coordinated, and a vehicle can be driven to travel normally.

Owner:SOUEAST

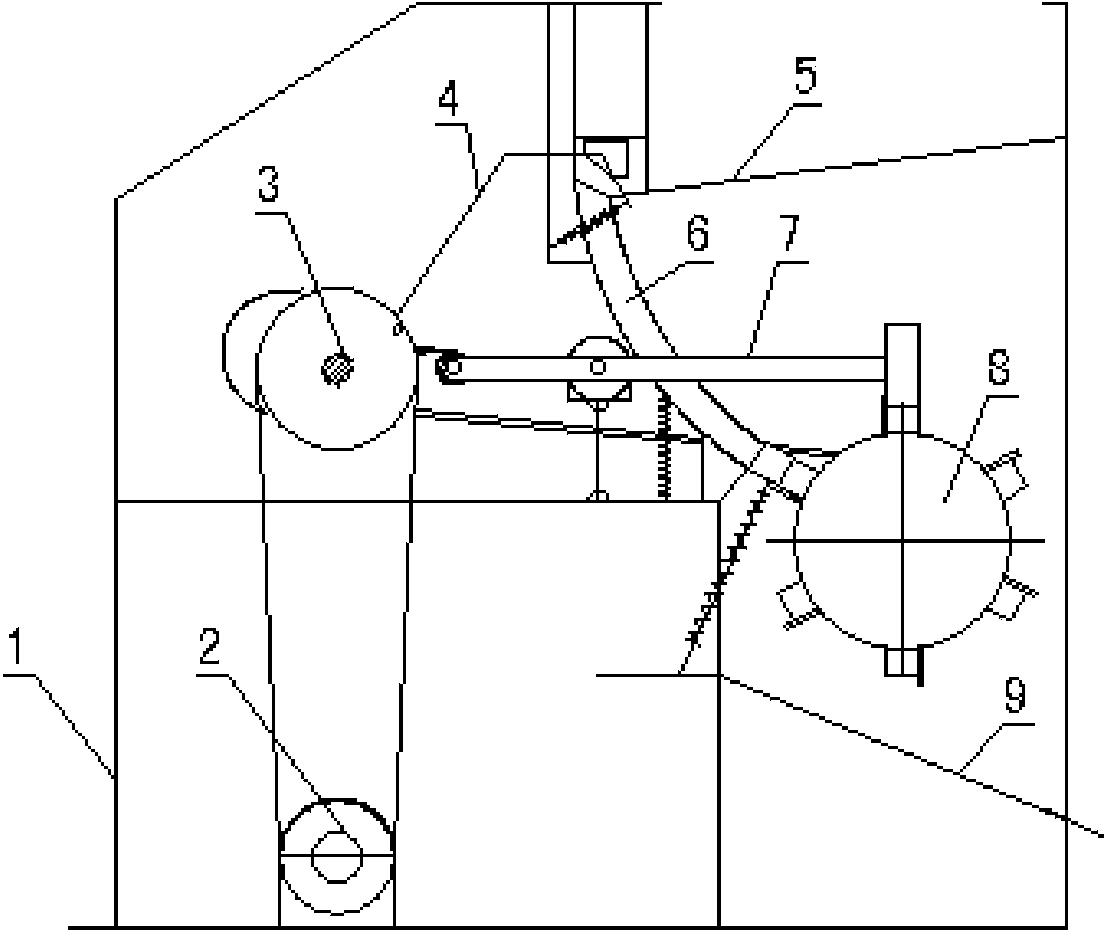

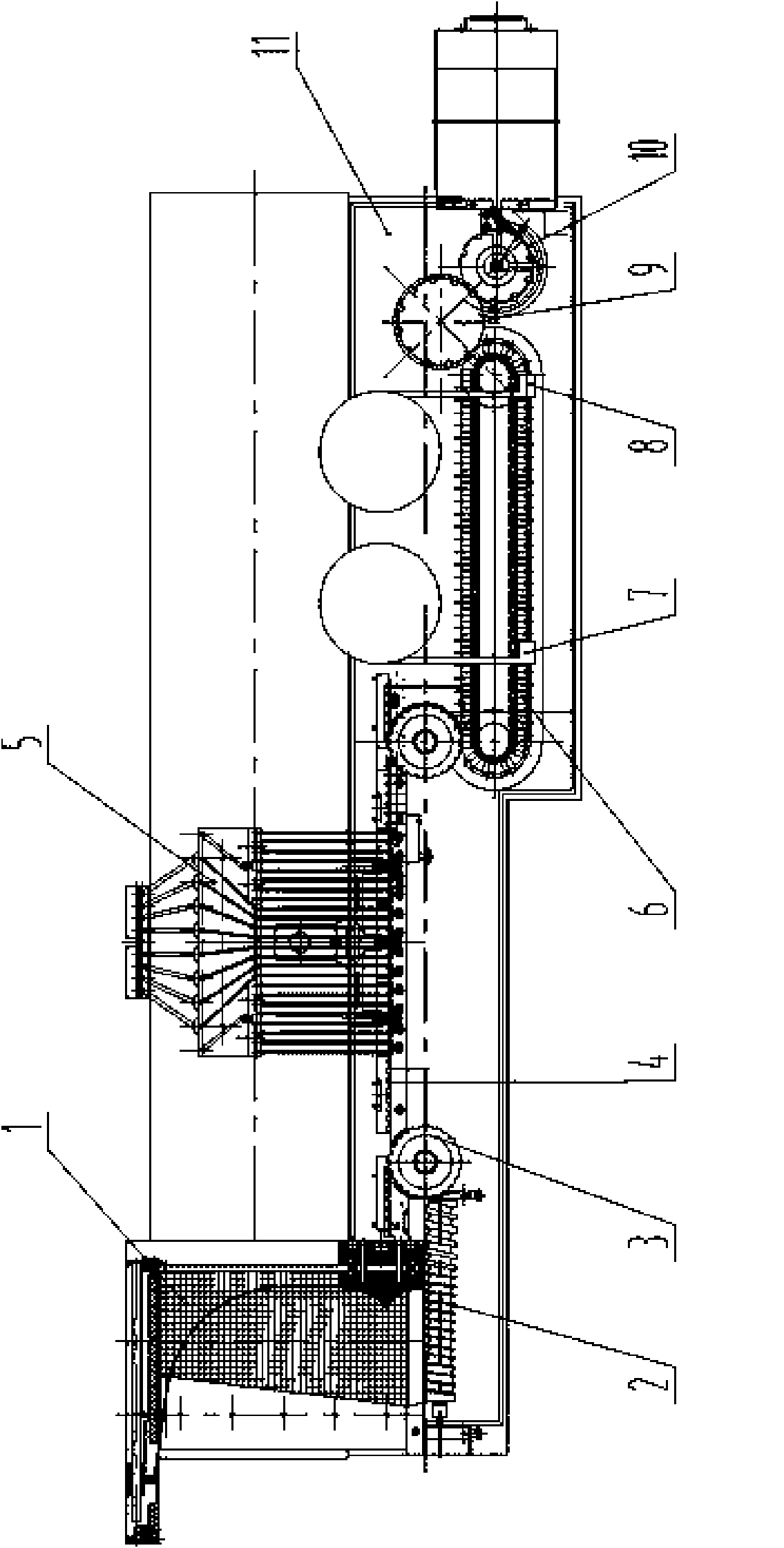

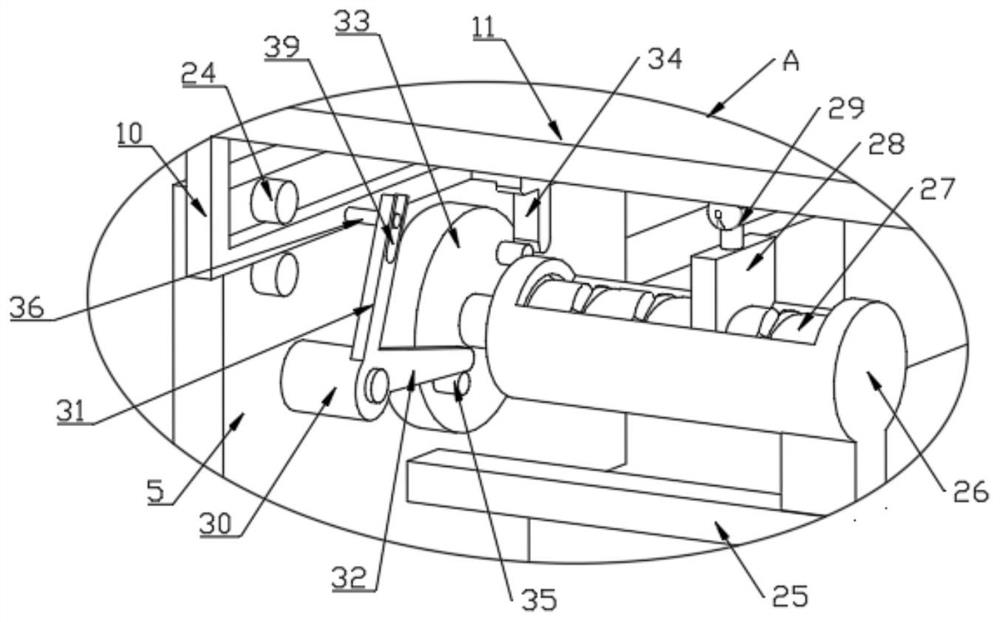

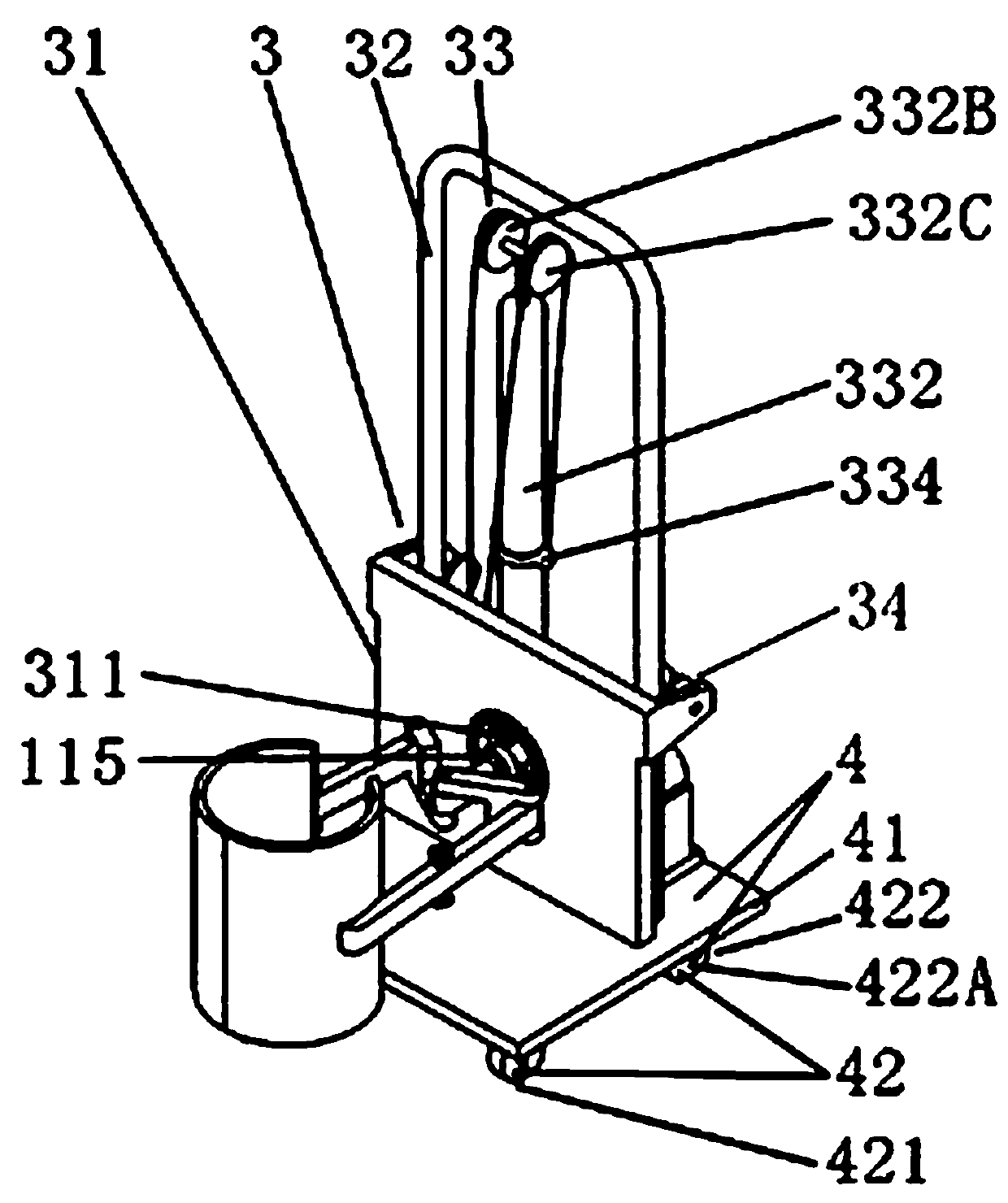

Pecan hulling machine

The invention discloses a pecan hulling machine. The pecan hulling machine comprises a machine frame, wherein the machine frame is provided with a feed device, a hulling device, a discharge device and a power transmission device, wherein the feed device comprises a feed hopper and a feed pipe; the hulling device comprises a feed cylinder and a beating rod assembly; a plurality of outwards convex hammer bases are evenly arranged on the circumference of the feed cylinder; a plurality of small concave pits are formed in the inwards concave surfaces of the hammer bases; the beating rod assembly comprises a beating rod idler wheel, a beating rod, a beating rod bearing base, a beating rod hammer and a beating rod spring; the front end and the rear end of the beating rod are provided with the beating rod hammer and the beating rod idler wheel respectively; the middle of the beating rod is hinged to the beating rod bearing base to form a lever fulcrum; the upper end of the beating rod spring is connected to the beating rod; the lower end of the beating rod spring is fixed to the machine frame; the beating rod is driven through a cam mechanism to vertically swing; the cam mechanism comprises a cam and a flat board; the flat board is arranged at the opposite end of the convex surface of the cam. The pecan hulling machine has the advantages that granules of hulled pecans are full and low in degree of breakage, the level of integration and degree of automation are high, the hulling efficiency is high, and cost is low.

Owner:丁孝德

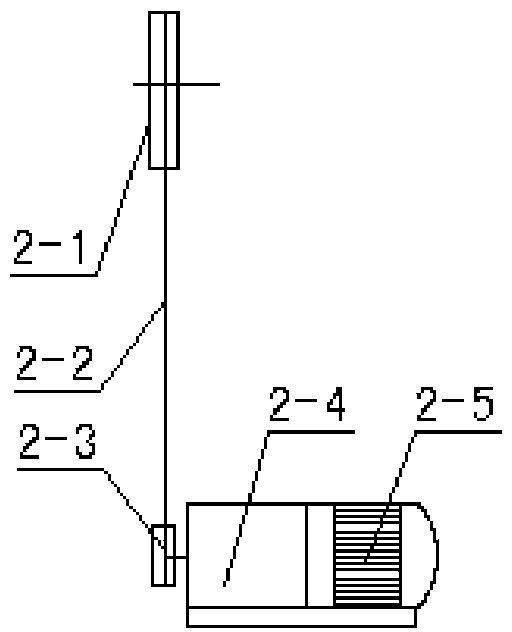

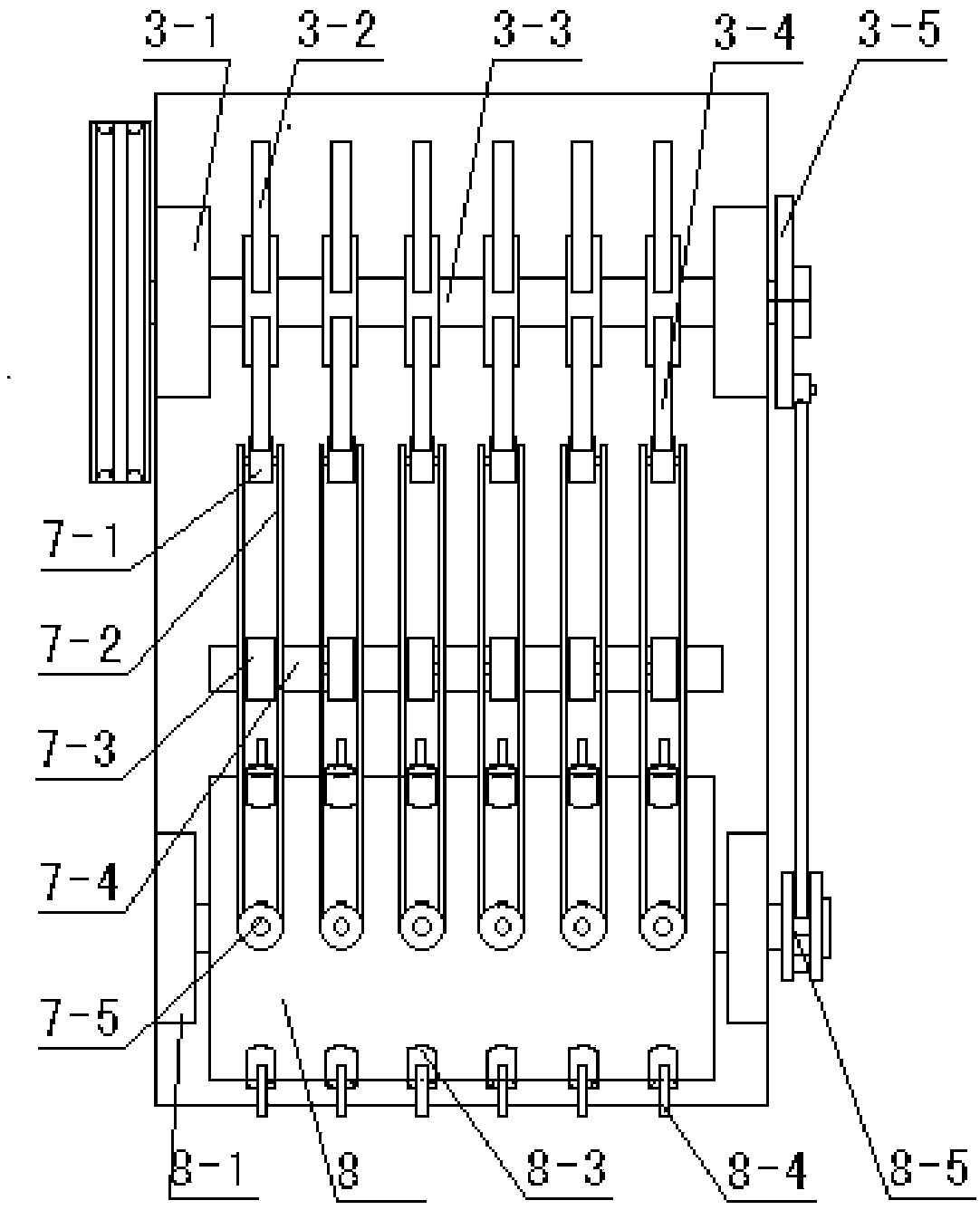

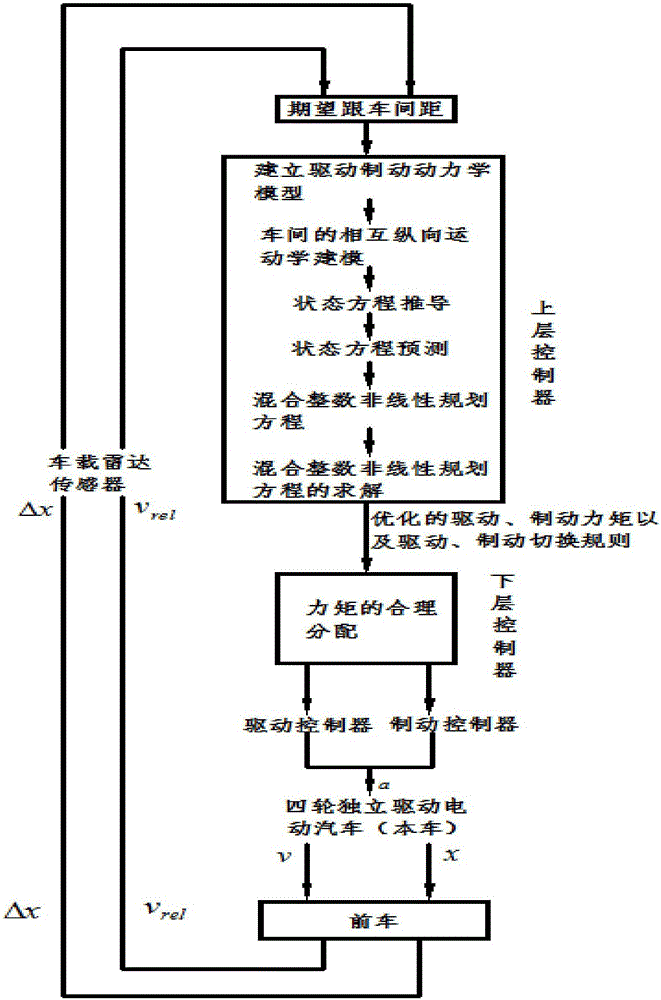

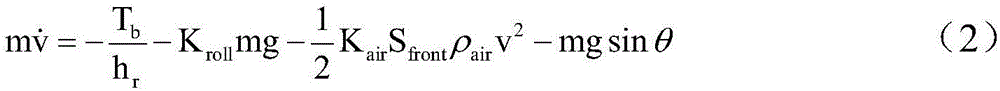

Driving-and-braking-optimal-switching electric-automobile adaptive cruise control method

ActiveCN106882079AOperational CoordinationReduce complexitySpeed controllerElectric devicesWork statusBrake torque

The invention discloses a driving-and-braking-optimal-switching electric-automobile adaptive cruise control method. The driving-and-braking-optimal-switching electric-automobile adaptive cruise control method includes the following steps that ideal driving-and-braking torque and the driving-and-braking switching rule are calculated through an upper controller; the ideal driving-and-braking torque is distributed on four wheels through a lower controller. According to the driving-and-braking-optimal-switching electric-automobile adaptive cruise control method, the driving-and-braking-optimal-switching adaptive cruise control strategy is designed and converted into a real-time mixed-integer nonlinear programming proposition through the upper controller according to the current road environment and the driving requirements, the proposition is solved through the double-nesting solving algorithm based on the modified genetic algorithm, and the driving-and-braking switching rule and the corresponding driving / braking controlling torque are obtained. The torque is distributed by the lower controller to hub motors through vertical loads according to the ideal driving-and-braking torque calculated by the upper controller to allow wheels to harmoniously run. The number of actions of a driving actuator and a braking actuator is reduced, and the wheels tend to be in the best working state accordingly.

Owner:DALIAN UNIV OF TECH

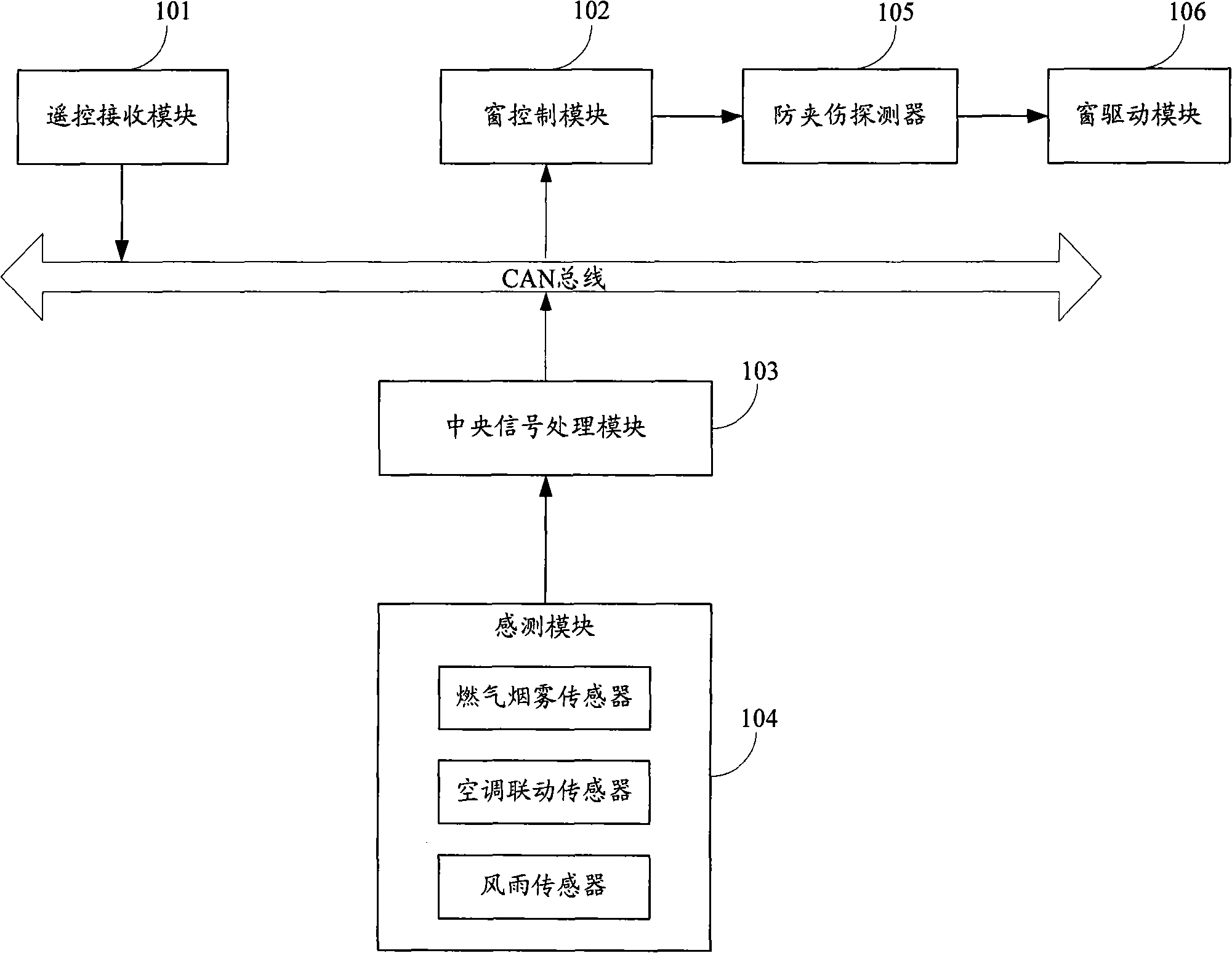

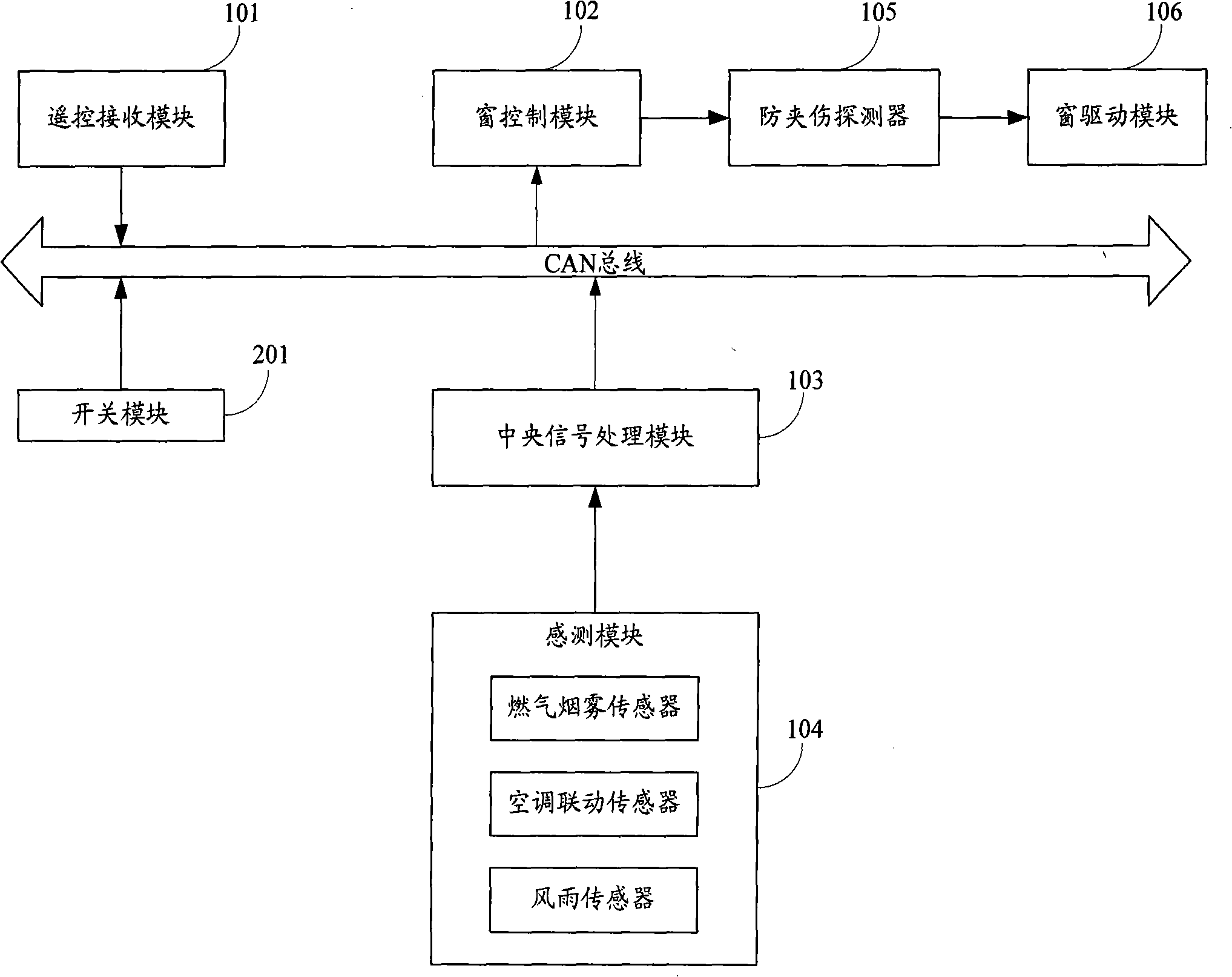

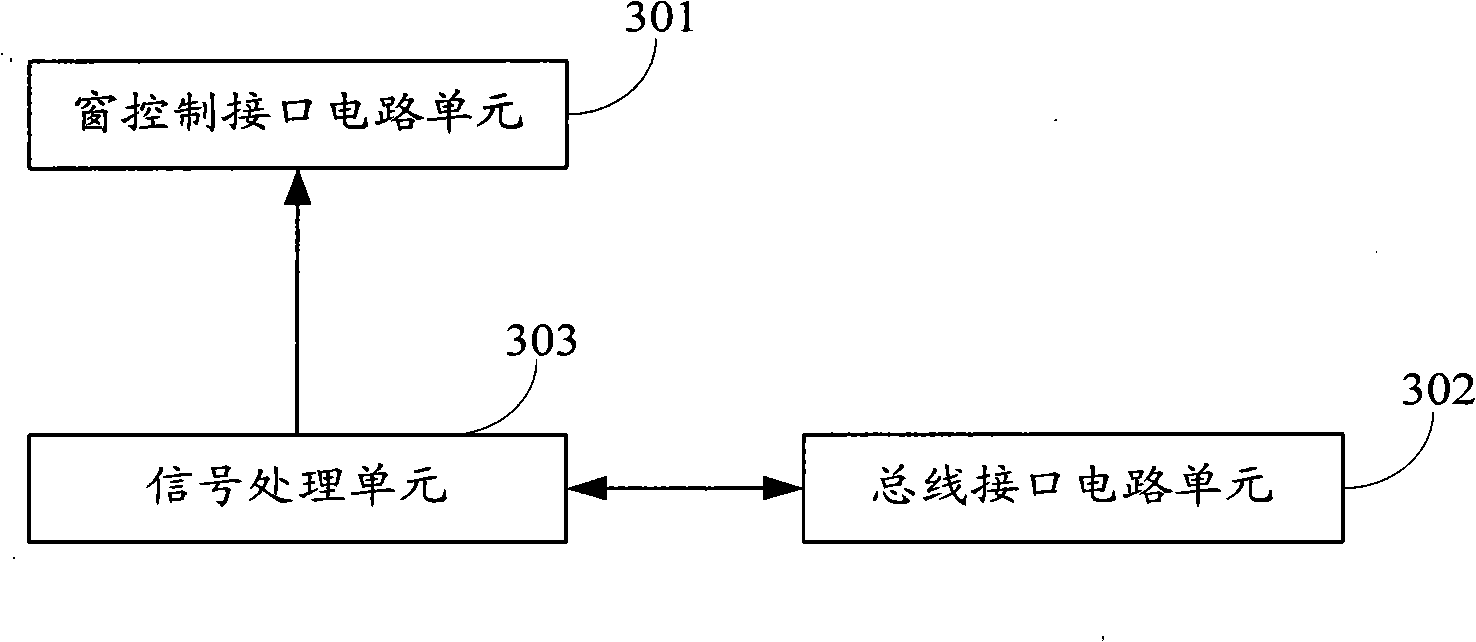

Intelligent window centralized control system

InactiveCN101265778AOperational CoordinationAchieving complex control purposesMechanical apparatusSpace heating and ventilation safety systemsEmbedded systemIntelligent control

The invention is applicable to the field of intelligent control, and provides an intelligent window centralized control system. The system comprises a sensing module used for collecting abnormal signals or air conditioner switching value signals and outputting signals to a central signal processing module for further processing; the central signal processing module used for converting the signals outputted by the sensing module into a data flow suitable for bus transmission and further sending an alarm signal when an abnormal signal is collected; a window control module used for receiving the data flow outputted by the central signal processing module and converting into control signals and further outputting; and a window driving module used for driving the window to open and close. The window centralized control system is capable of integrating the functions of fire control, intelligent smoke removal, intelligent theft proof, automatic weather proof and remote control into a system, centrally controlling each functional module of the system, functioning in coordination and achieving the purpose of complex control; meanwhile, the system can freely combine the functional modules according to requirements so as to meet the need on various occasions.

Owner:SHENZHEN ZHONGFENG INTELLIGENCE TECH

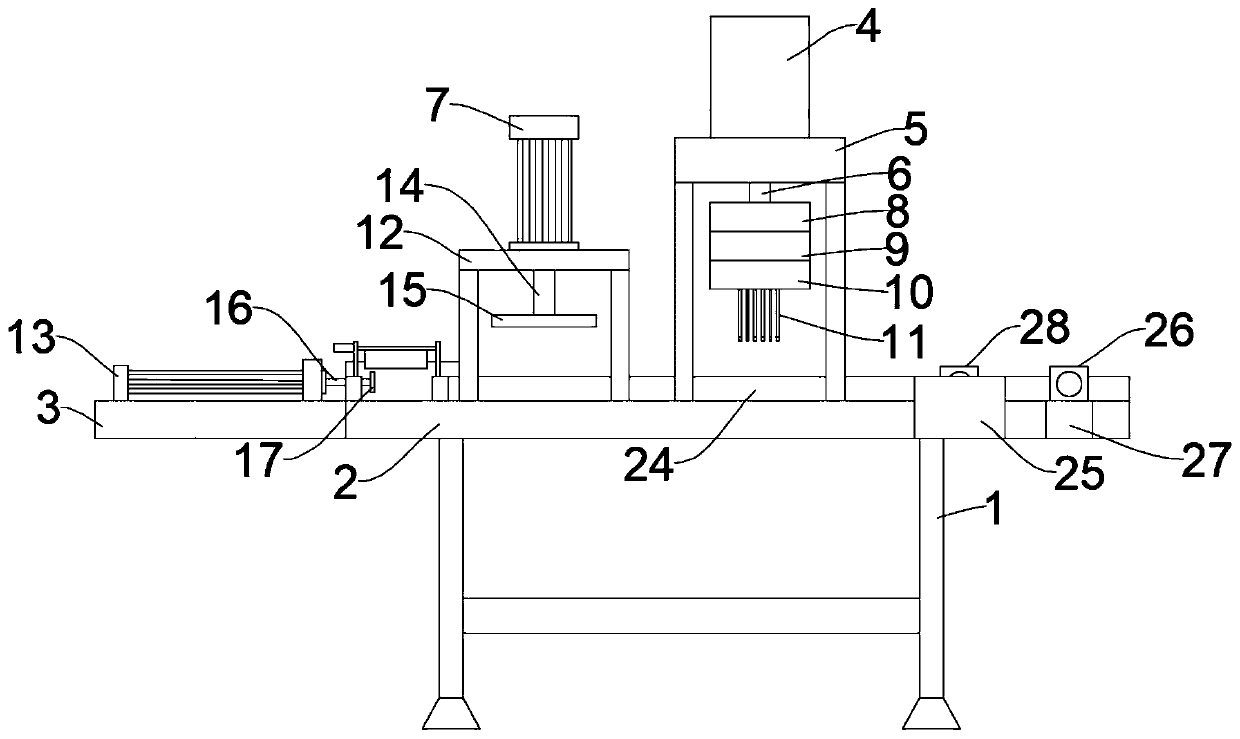

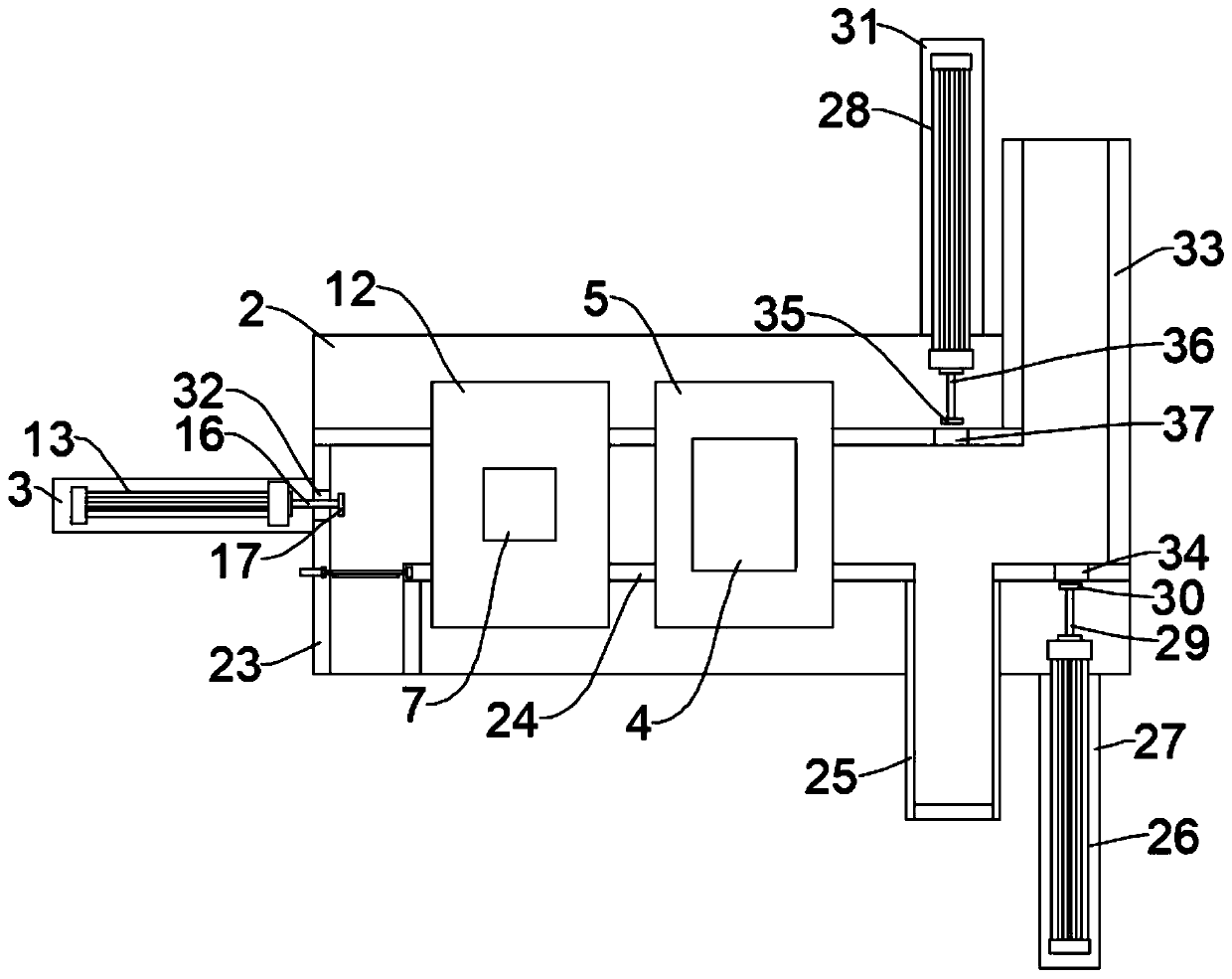

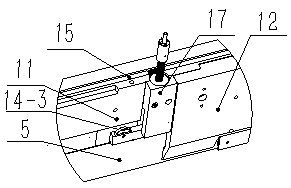

Linear filling plug-hanging and cover-hanging cover pressing machine

InactiveCN101643191ASafe and reliable workReasonable connectionCap application using vaccuumClosure using stoppersBottle

The invention relates to a linear filling plug-hanging and cover-hanging cover pressing machine which is used for providing a plug and a cover for a bottle type packing container used for the pharmaceuticals and food industry and is especially suitable for packing oral liquid. The linear filling plug-hanging and cover-hanging cover pressing machine of the invention comprises a bottle feeding-arranging component, a filling component, a cover-pressing component, a bottle discharge thumb wheel component and a machine stand, wherein a plug-hanging component and a cover-hanging component are arranged between the filling component and the cover-pressing component. The invention divides the traditional plug-cover combined type cover hanging component into two separated components, namely the plug-hanging component and the cover-hanging component, thereby putting an end to pollution possibly generated by the traditional hanging cover and preventing the normal running of the machine from beinginfluenced by the malposition of the plug and the cover. The invention has the advantages of reasonable design, novel structure, high degree of standardization and universalization and low productioncost.

Owner:TRUKING TECH LTD

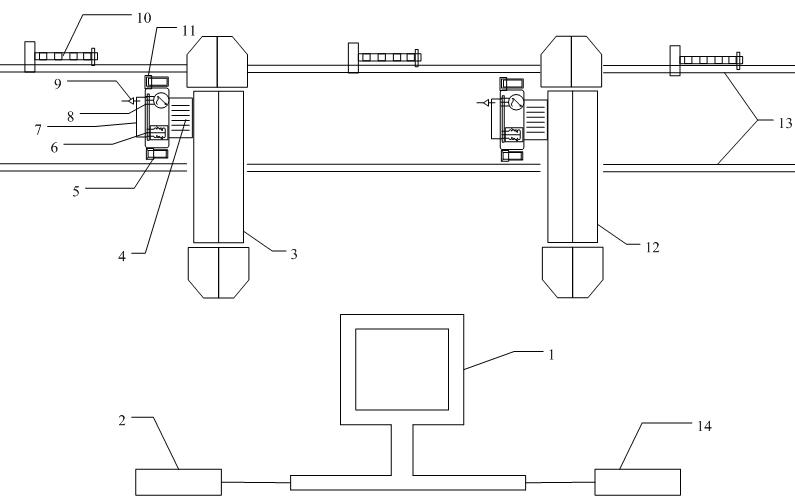

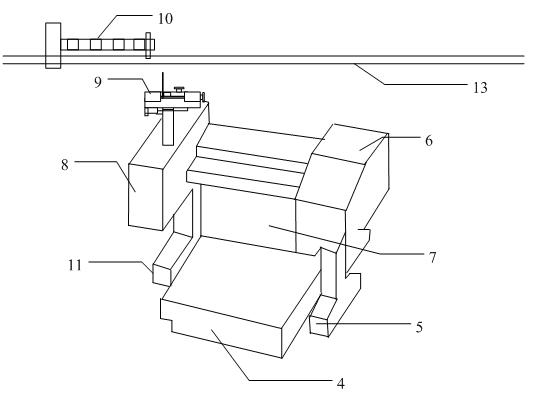

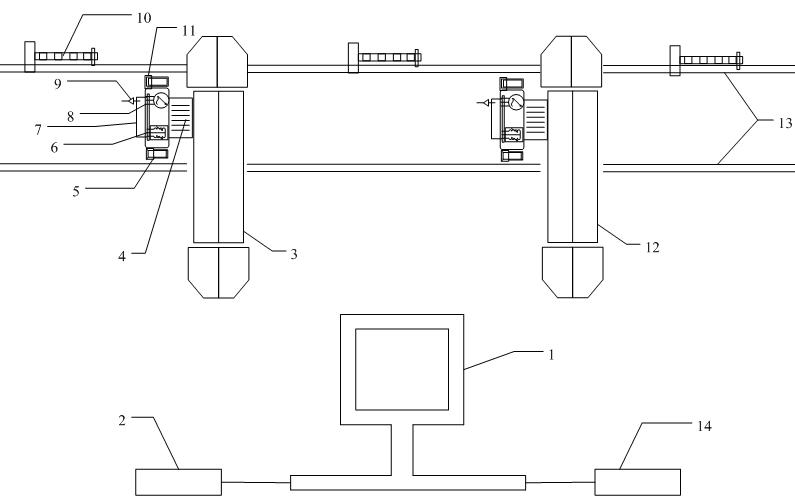

Intelligent control equipment for coordinating operation of cranes

InactiveCN102092639ANot easy to loseReal-time monitoring of operationsLoad-engaging elementsInformatizationCrane scheduling

The invention discloses intelligent control equipment for coordinating the operation of cranes, which comprises a personal computer (PC), ground receiving equipment, ground transmission equipment, the cranes, intelligent controllers, crane receiving equipment, crane transmission equipment and electronic tags, wherein the PC, the ground receiving equipment and the ground transmission equipment are arranged on ground; the cranes are erected on an overhead support; coding cables are arranged on the support; the electronic tags are arranged on the coding cables; and the intelligent controller is arranged on one side of the crane. The intelligent control equipment can further perfect matched equipment for the communication of the cranes, monitor and accurately position the operation of the cranes in real time and dynamically regulate crane scheduling schemes, thereby improving the efficiency of coordinated operation of the cranes, improving the operation safety performance of the cranes, reducing the probabilities of accidents caused by the negligence of operators and increasing the informatization, automation and normalization degrees of crane operation areas.

Owner:SHENYANG UNIV

Vertical material-distributing device and material-distributing method

InactiveCN101077592AReduced splicing flatness requirementsGuaranteed decorative effectFeeding arrangmentsEngineeringClosed cavity

The present invention relates to one kind of vertical material distributing apparatus and process. The vertical material distributing apparatus includes one turnable platform capable of being turned into horizontal state or vertical state, one material box over the platform, one powder carrier with closed cavity, and one material feeder to fill the cavity with powdered material. The vertical material distributing process includes the following steps: setting the powder carrier on the turnable platform in horizontal state, forming one closed cavity with the material box and the powder carrier, turning the platform to vertical state, filling powdered material with the material feeder to the closed cavity, turning the platform reversely to horizontal state for the powdered material on the powder carrier, and feeding the powdered material with the powder carrier to the press for forming. The present invention has reasonable structure, high production efficiency and capacity of raising product quality.

Owner:KEDA INDUSTRIAL GROUP CO LTD

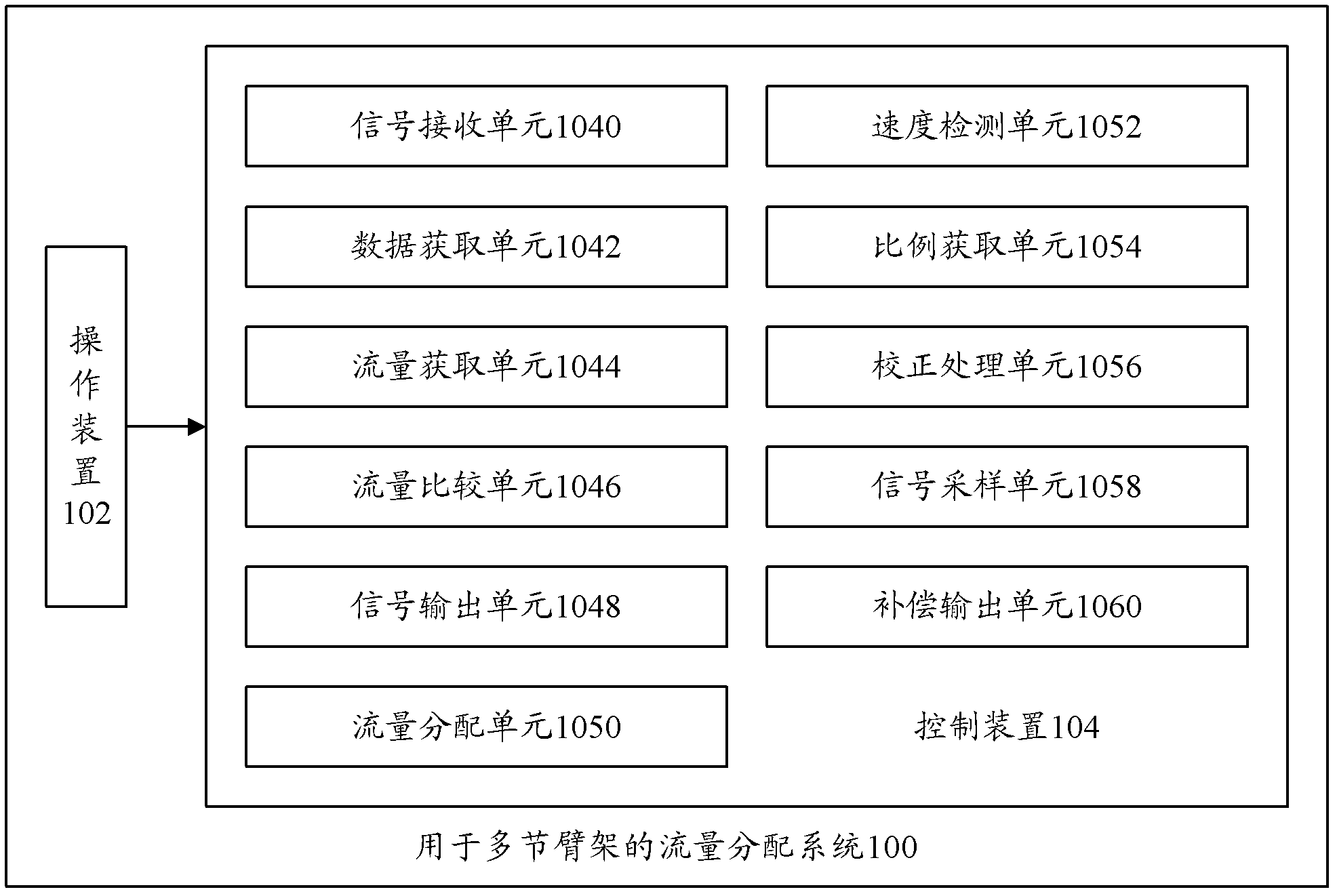

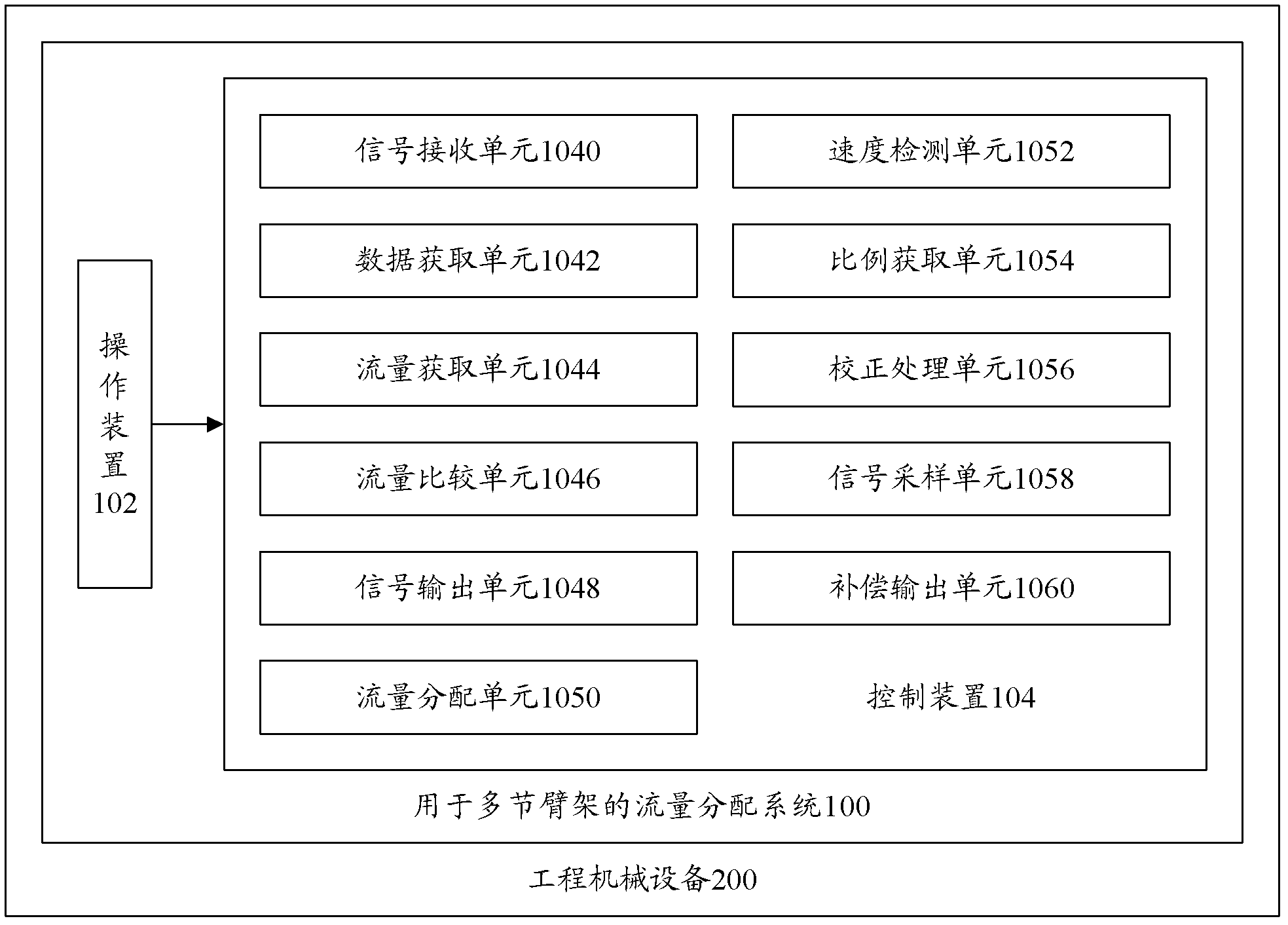

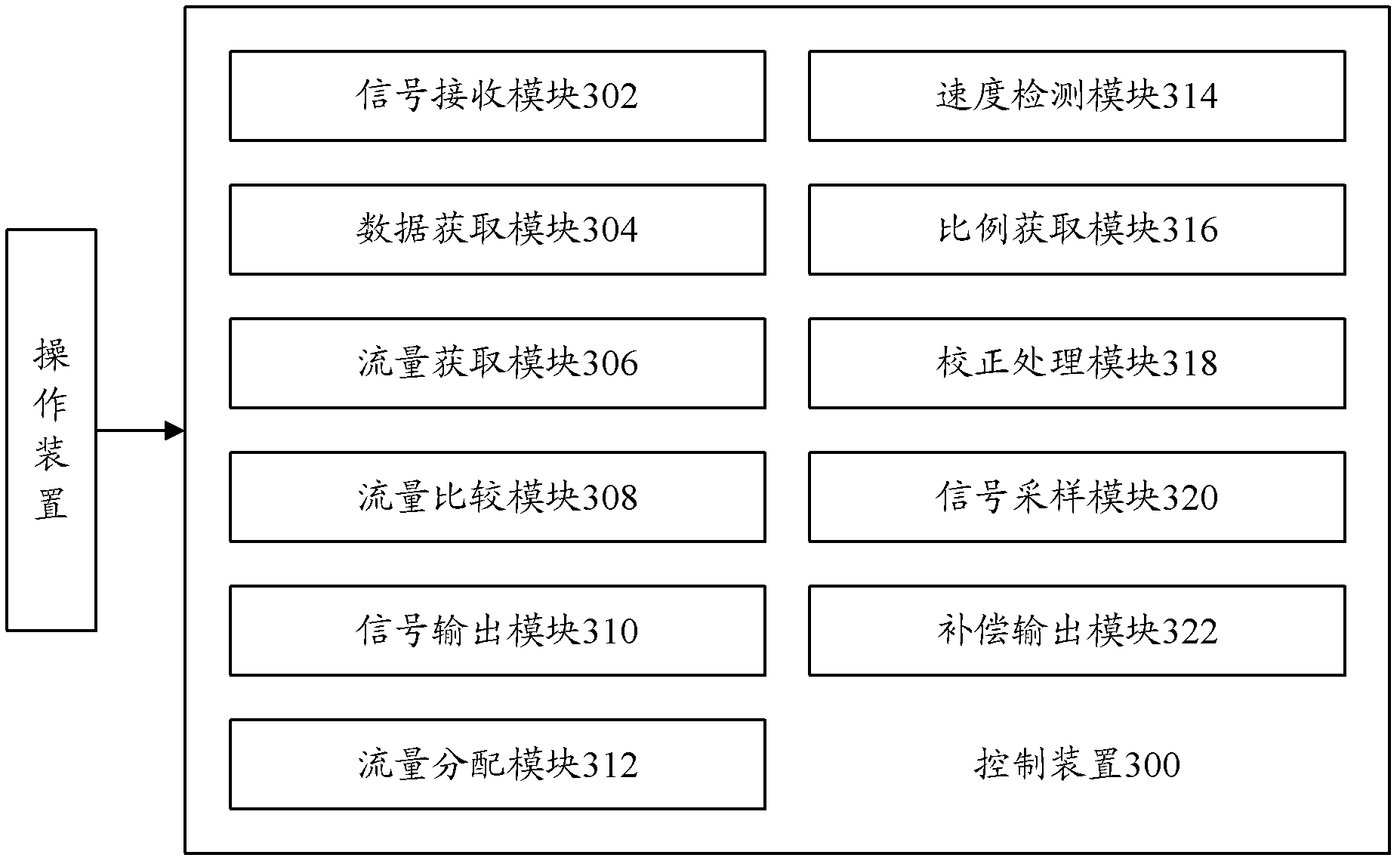

Flow distribution system, device and method for multi-section arm support, and engineering machine equipment

ActiveCN102493656AOperational CoordinationBuilding material handlingLoad-engaging elementsControl signalControl engineering

The invention provides a flow distribution system for a multi-section arm support. The system comprises an operating device and a control device, wherein the operating device is used for inducing the arm support operating action of a user and generating a corresponding operating command; and the control device is connected to the operating device and used for generating a corresponding control signal according to the operating command from the operating device and derating the control signal. Correspondingly, the invention also provides engineering machine equipment, and a flow distribution device and a flow distribution method for the multi-section arm support. Through the technical scheme, flow is reasonably distributed when the multi-section arm support is operated, and the action of each section of arm support can be operated in a coordinated mode.

Owner:SANY AUTOMOBILE MFG CO LTD

Organic lemon enzyme full-nutrition liquid and preparation method thereof

InactiveCN104783247AImprove absorption and utilizationImprove immunityFood scienceAdditive ingredientNutrient solution

The present invention provides an organic lemon enzyme full-nutrition liquid and a preparation method thereof, wherein the organic lemon enzyme full-nutrition liquid is prepared from the following components by weight: 5-10% of organic lemon enzyme, 5-10% of organic spiral algae powder, 10-20% of an organic corchorus olitorius juice, 10-20% of an organic kiwifruit juice, 20-30% of organic brown rice powder, 10-20% o organic sweet potato powder, 10-20% of organic soybean powder, 5-10% of brown sugar, 1-2% of a compound enzyme preparation, 1-2% of lactic acid bacteria, and purified water matched according to a weight ratio of 100:300. According to the present invention, the organic lemon enzyme full-nutrition liquid has characteristics of nature and green property, no pollution, organic life concept support, complete and balance nutrition, rich active ingredients, and nutrient absorption and utilization rate improving, such that the body functions are subjected to coordination operation, and the immunity of the human body is improved.

Owner:广东盆地一号生物产业有限公司

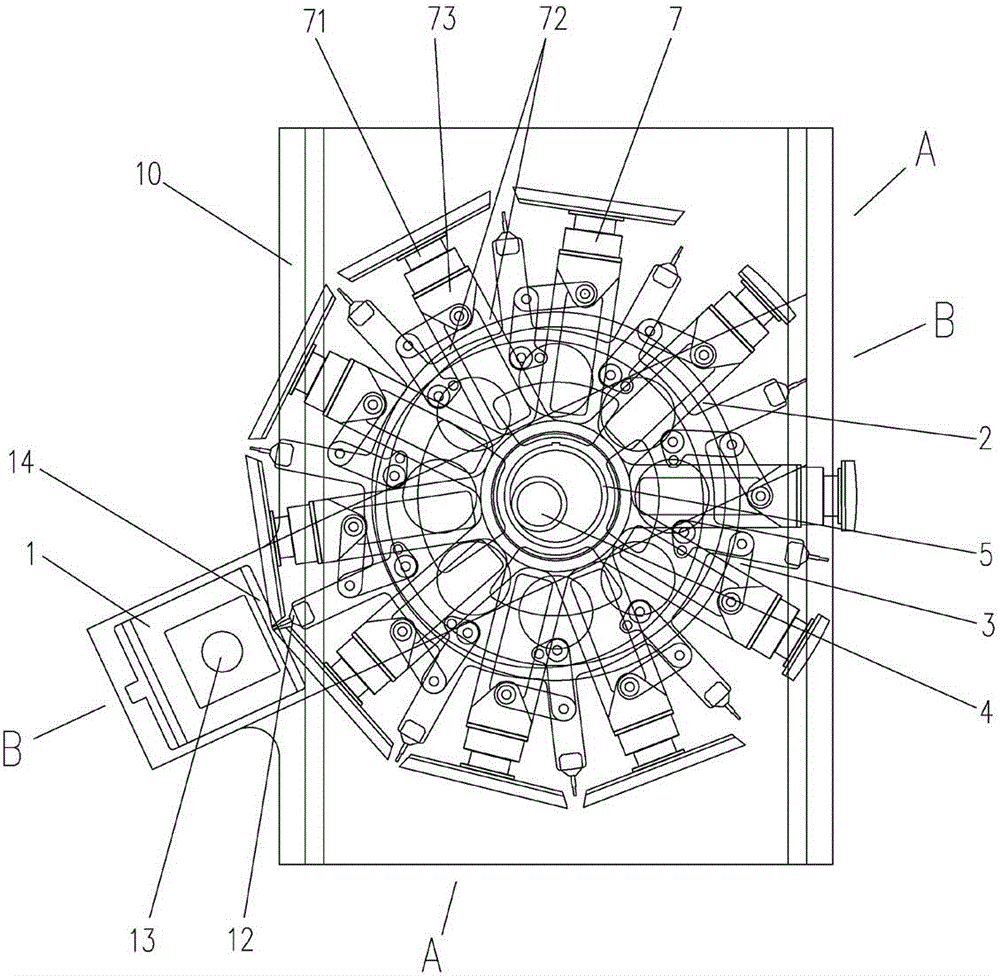

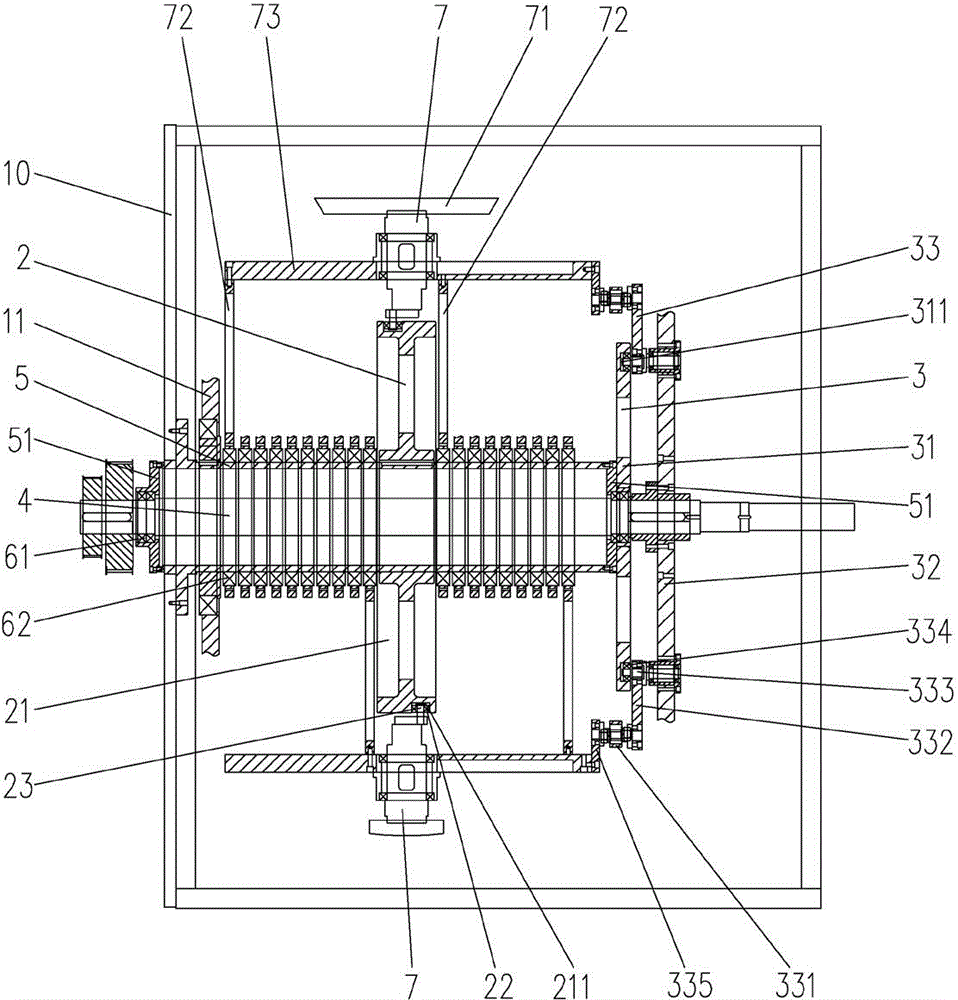

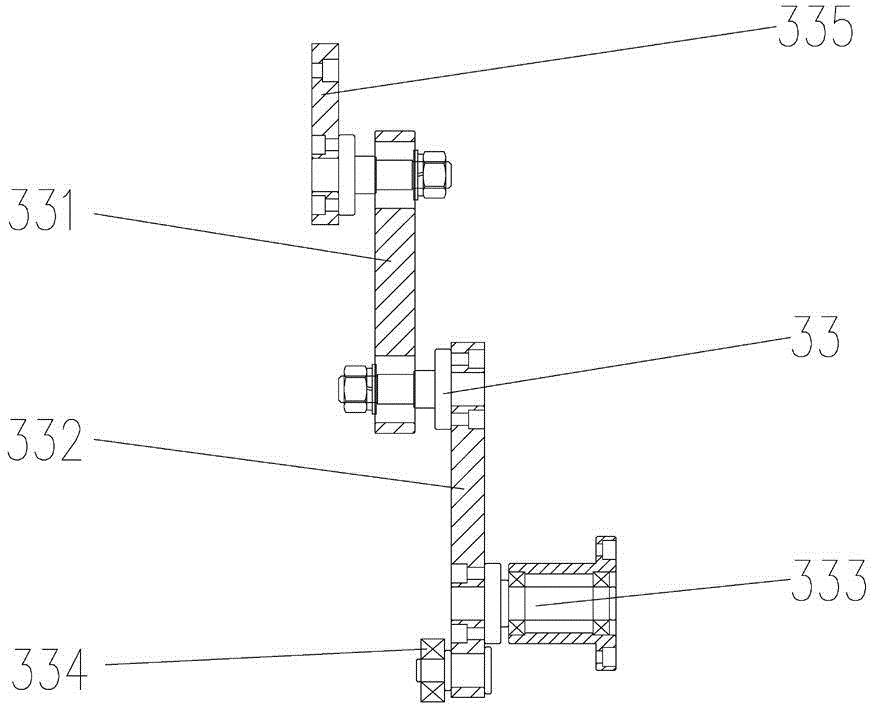

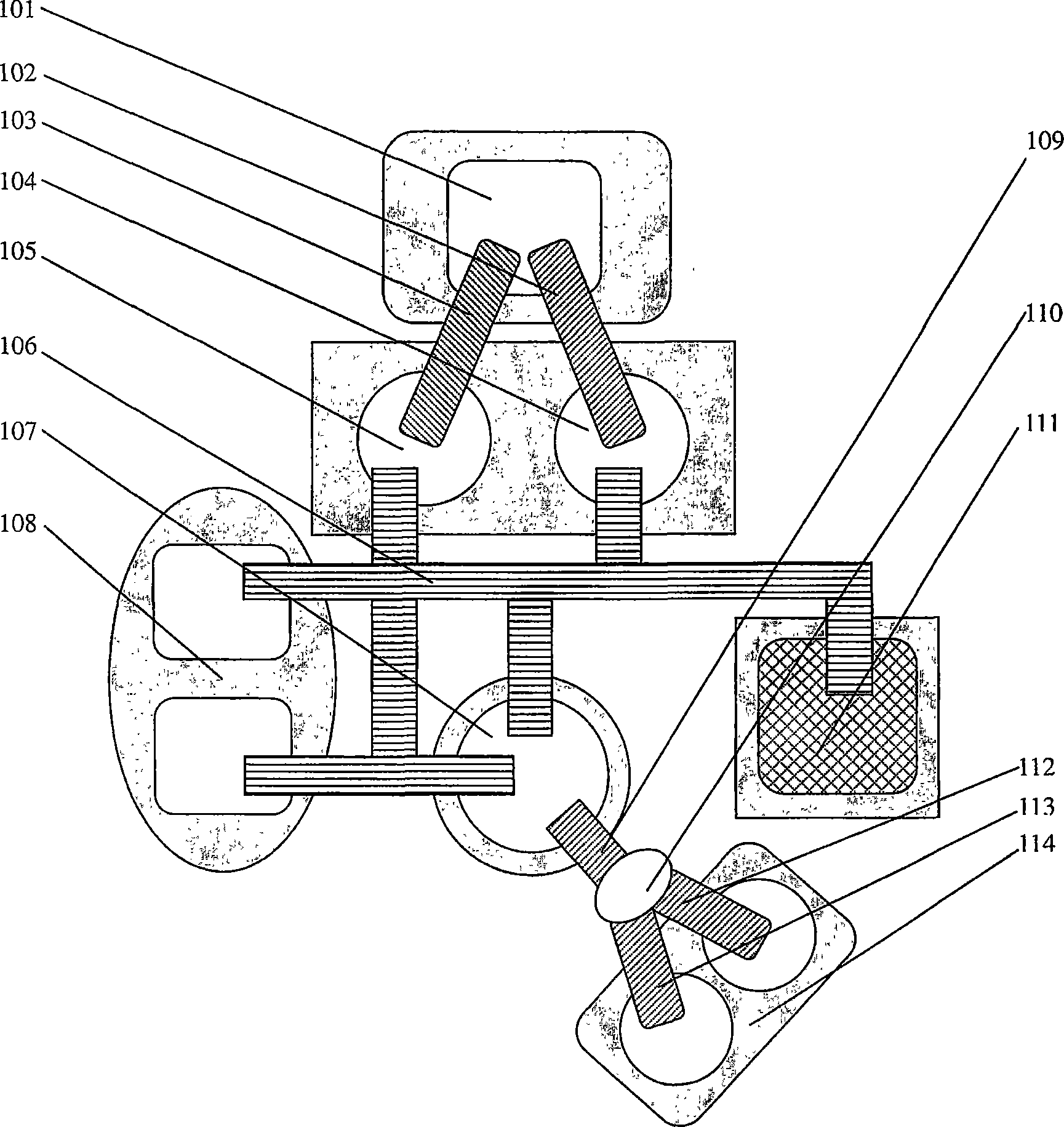

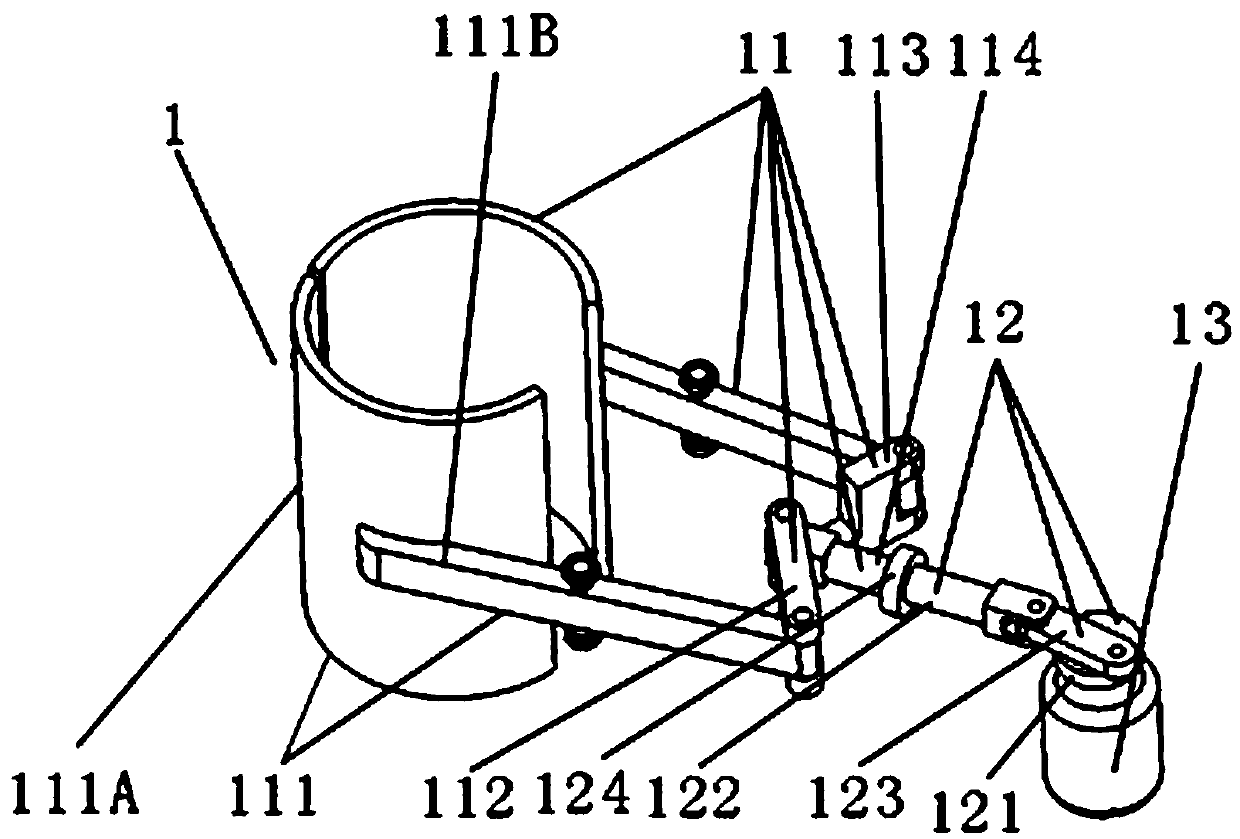

Cutting-off, steering and speed changing device for hygienic product production

ActiveCN104858916AOperational CoordinationEfficient integrationMetal working apparatusSurface layerEngineering

The invention discloses a cutting-off, steering and speed changing device for hygienic product production. The cutting-off, steering and speed changing device comprises a rack (10), an adsorption mechanism (7), a cutting-off mechanism (1) used for cutting off an elastic material adsorbed on the adsorption mechanism (7), a steering mechanism (2) used for steering the adsorption mechanism (7) and a speed changing mechanism (3) used for changing the speed of the adsorption mechanism (7), and the cutting-off mechanism (1), the steering mechanism (2) and the speed changing mechanism (3) are fixed to the rack (10). According to the cutting-off, steering and speed changing device for hygienic product production, the cutting-off mechanism and the steering mechanism are effectively integrated in the same device; the speed changing mechanism is further arranged, so that when moved and attached, the elastic material is matched with a product surface layer on a combining device in speed; the device is compact in structure, reasonable in arrangement, powerful in function and high in working efficiency, and all the mechanisms operate in a coordinating mode.

Owner:JINJIANG SHUNCHANG MACHINE MFG

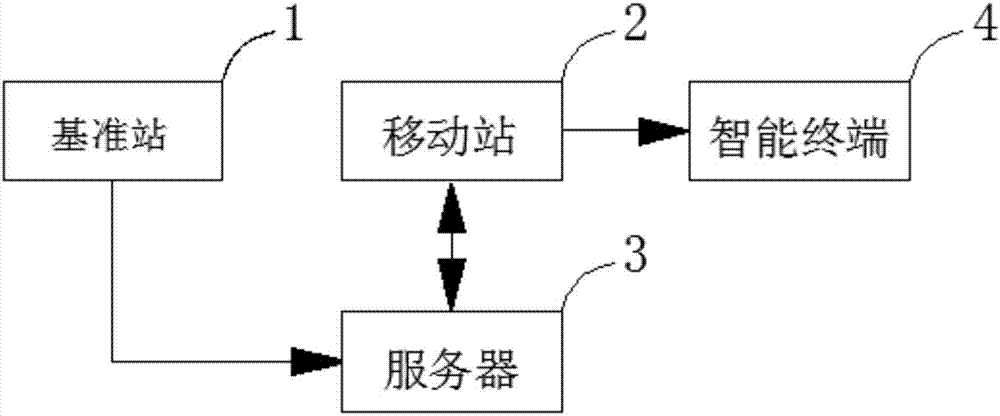

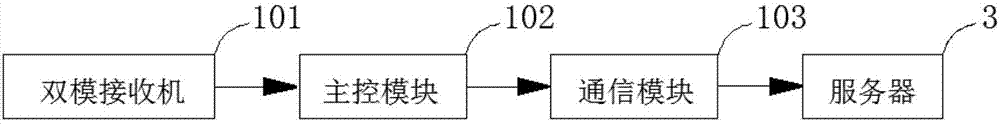

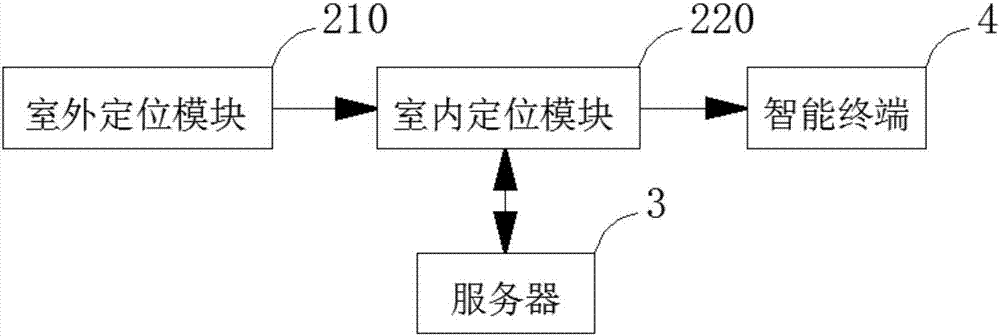

Reverse vehicle searching positioning system and method

InactiveCN107272034APositioning real-time correctionReal-time high-precision positioningSatellite radio beaconingCarrier signalSatellite orbit

The invention relates to a reverse vehicle searching positioning system and method. The system comprises a reference station, a mobile station, a server and an intelligent terminal, wherein a satellite signal is processed by the reference station to acquire a satellite orbit and a clock error correction number, through carrier wave phase smooth pseudo range, a difference correction number and a correction number change rate are generated and transmitted to the server for storage, the satellite signal is processed through the mobile station to generate a first positioning data which is transmitted to the server or is combined with first positioning data for carrying out vehicle positioning, preliminary positioning data is generated, final positioning data is transmitted to the intelligent terminal, the positioning data is pre-stored by the server, the first positioning data or the preliminary positioning data is corrected to generate the final positioning data, and the final positioning data is displayed through the intelligent terminal. The system is advantaged in that positioning of the mobile station can be corrected in real time, high precision positioning of the vehicle can be realized in real time, the positioning signal is transmitted to the intelligent terminal, and a user is facilitated to realize reverse vehicle searching.

Owner:GUILIN UNIV OF ELECTRONIC TECH

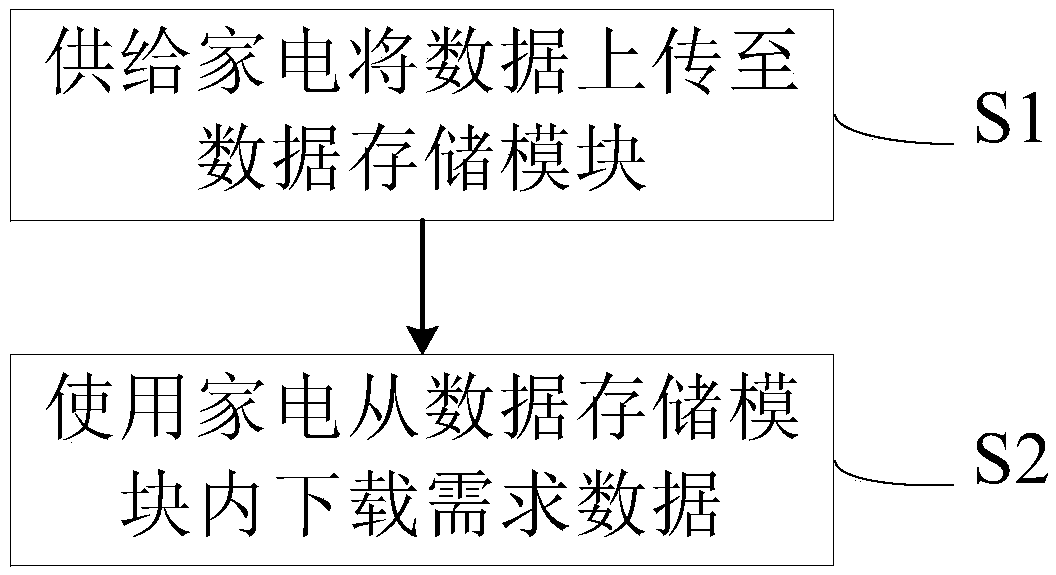

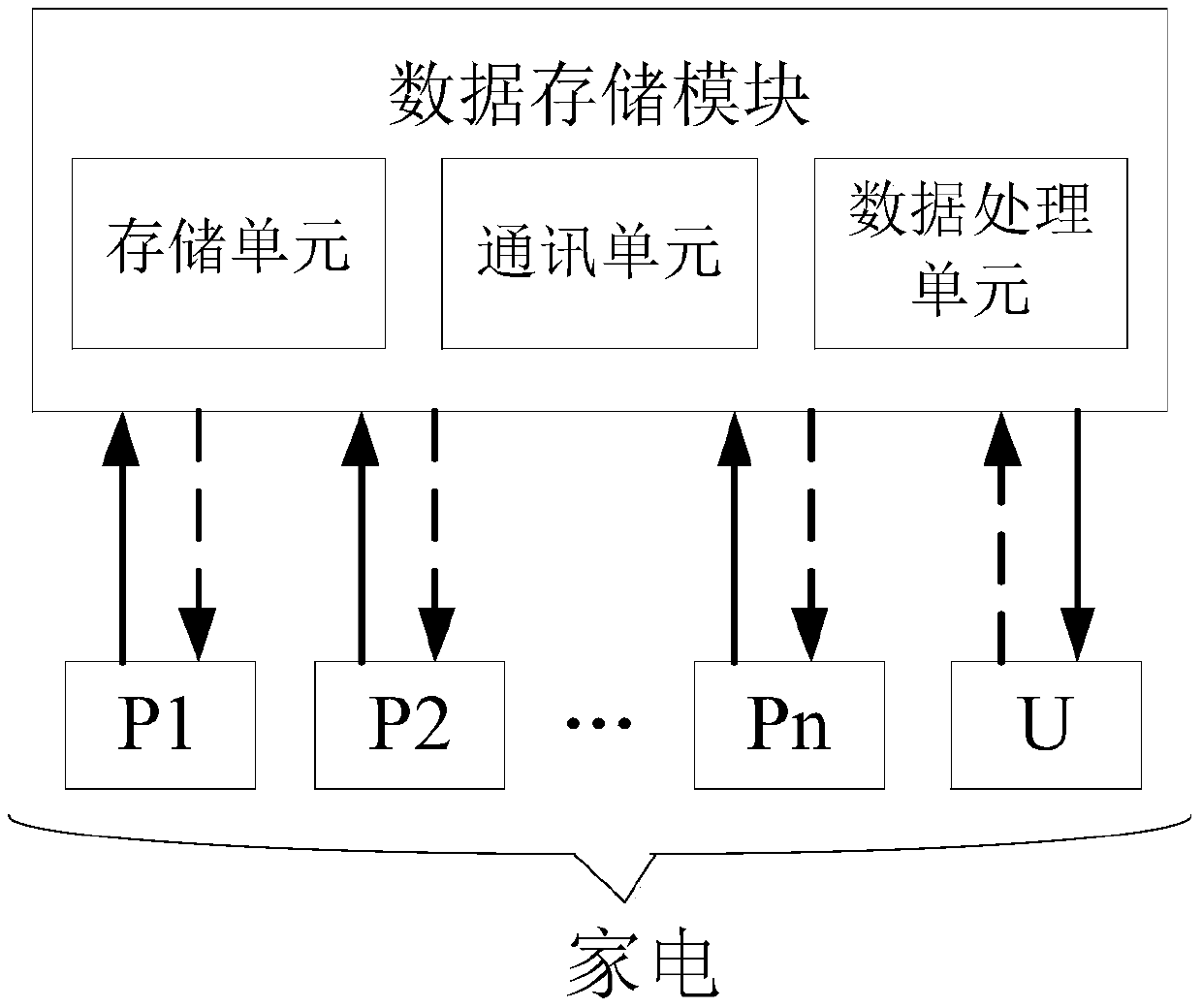

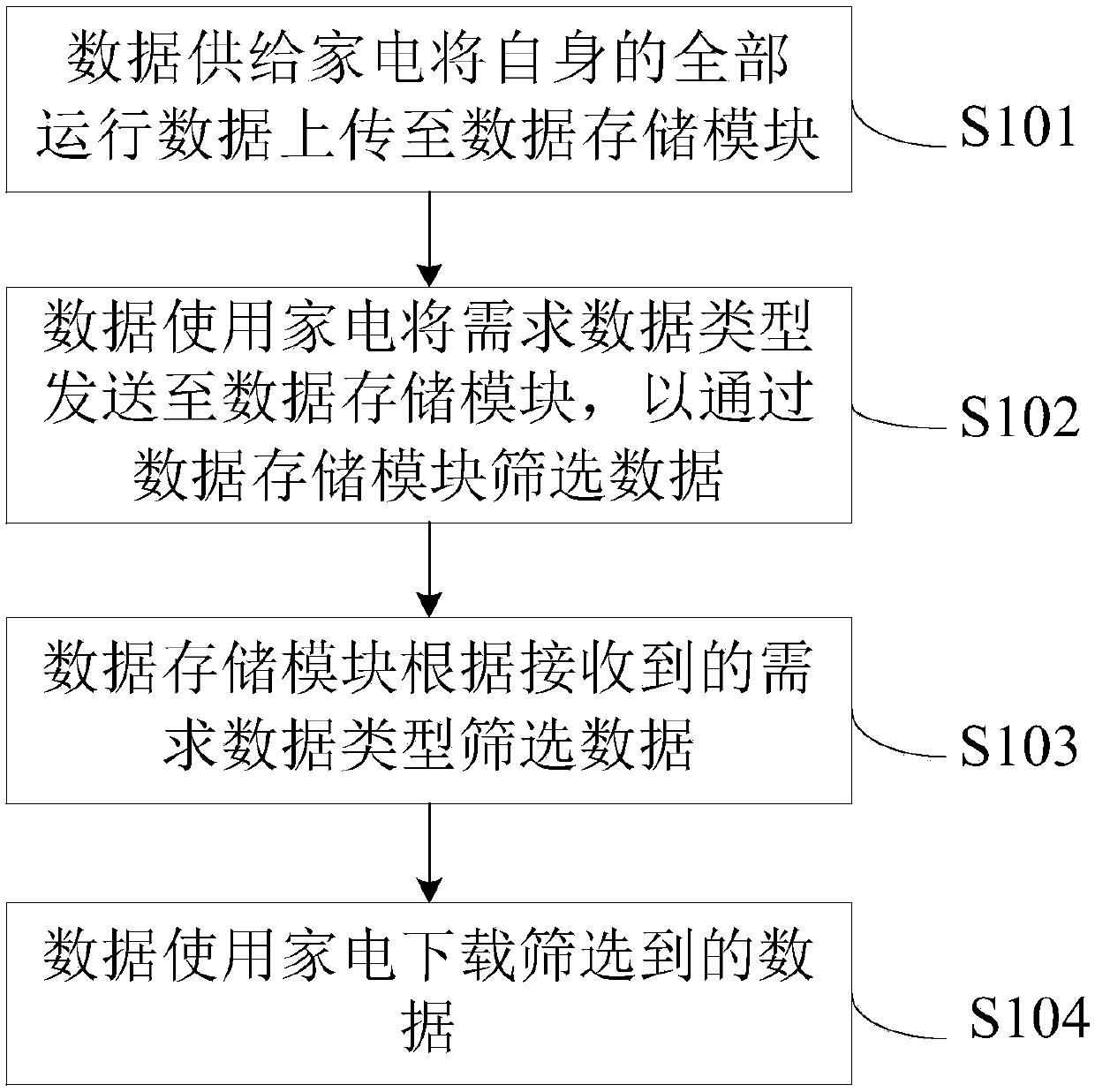

Control method for household appliance system

PendingCN110850724AReduce the number of operationsImprove job stabilityComputer controlData switching by path configurationControl engineeringComputer science

The invention belongs to the technical field of communication, and particularly relates to a control method for a household appliance system. According to the control method, information sharing amonghousehold appliances can be realized by transmitting data between the household appliances and a data storage module. When certain household electrical appliance needs information to set a working program, the household electrical appliance can download information from the data storage module spontaneously, a central control module needs not to make regulation between the data storage module andthe household electrical appliances, connection between the data storage module and the household electrical appliances is less tight, operation links and fault rate during work of the household appliances are reduced, and the working stability of the household appliances is improved. In addition, various types of information can be obtained without configuring various sensors for different household electrical appliance, the sensor of certain electrical appliance can obtain basic information for setting working program of the electrical appliance itself as well as effectively information collected by other electrical appliances, the electrical appliances can work coordinatedly, and the intelligent running degree of the electrical appliances is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

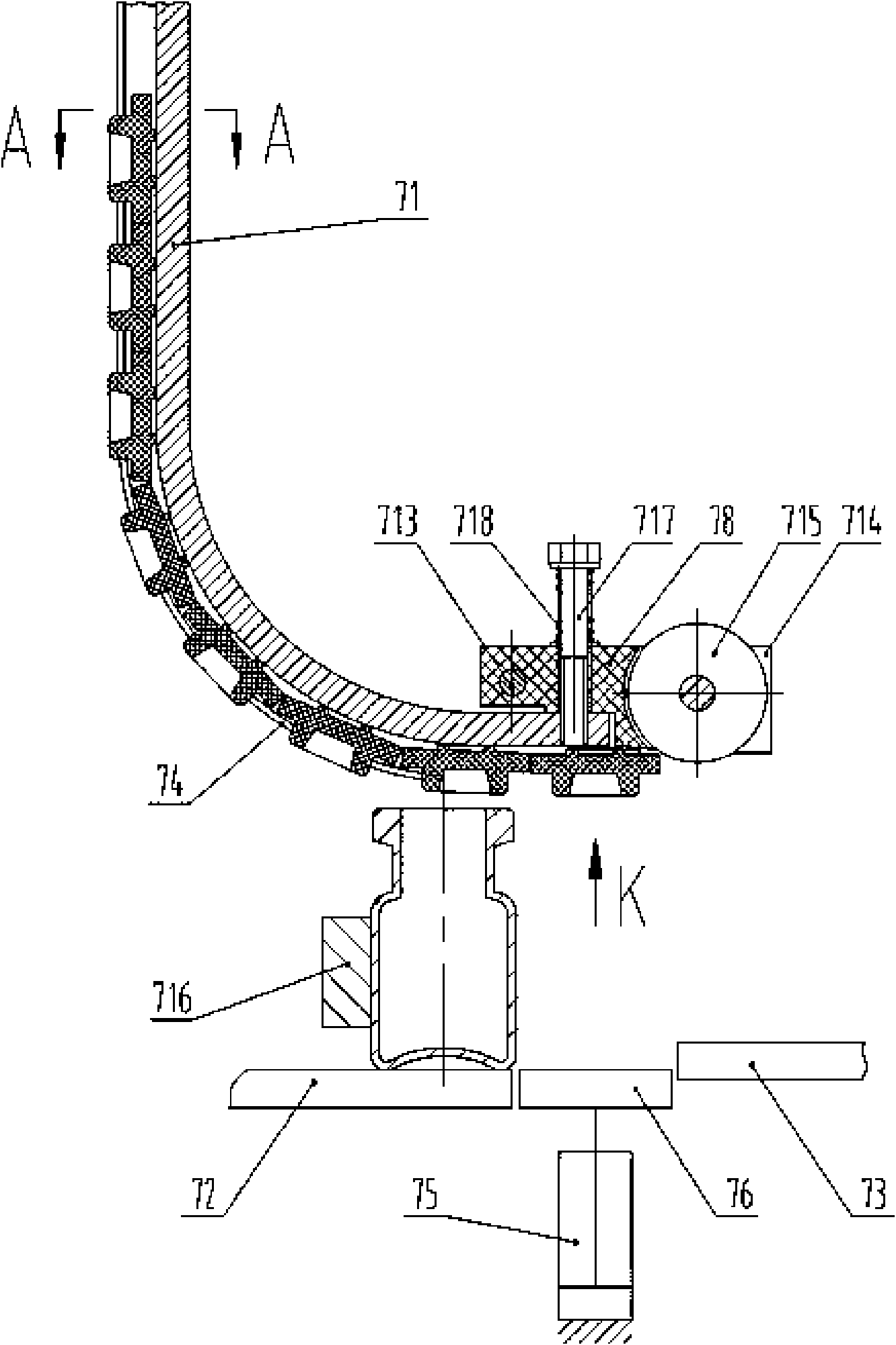

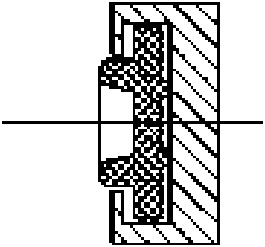

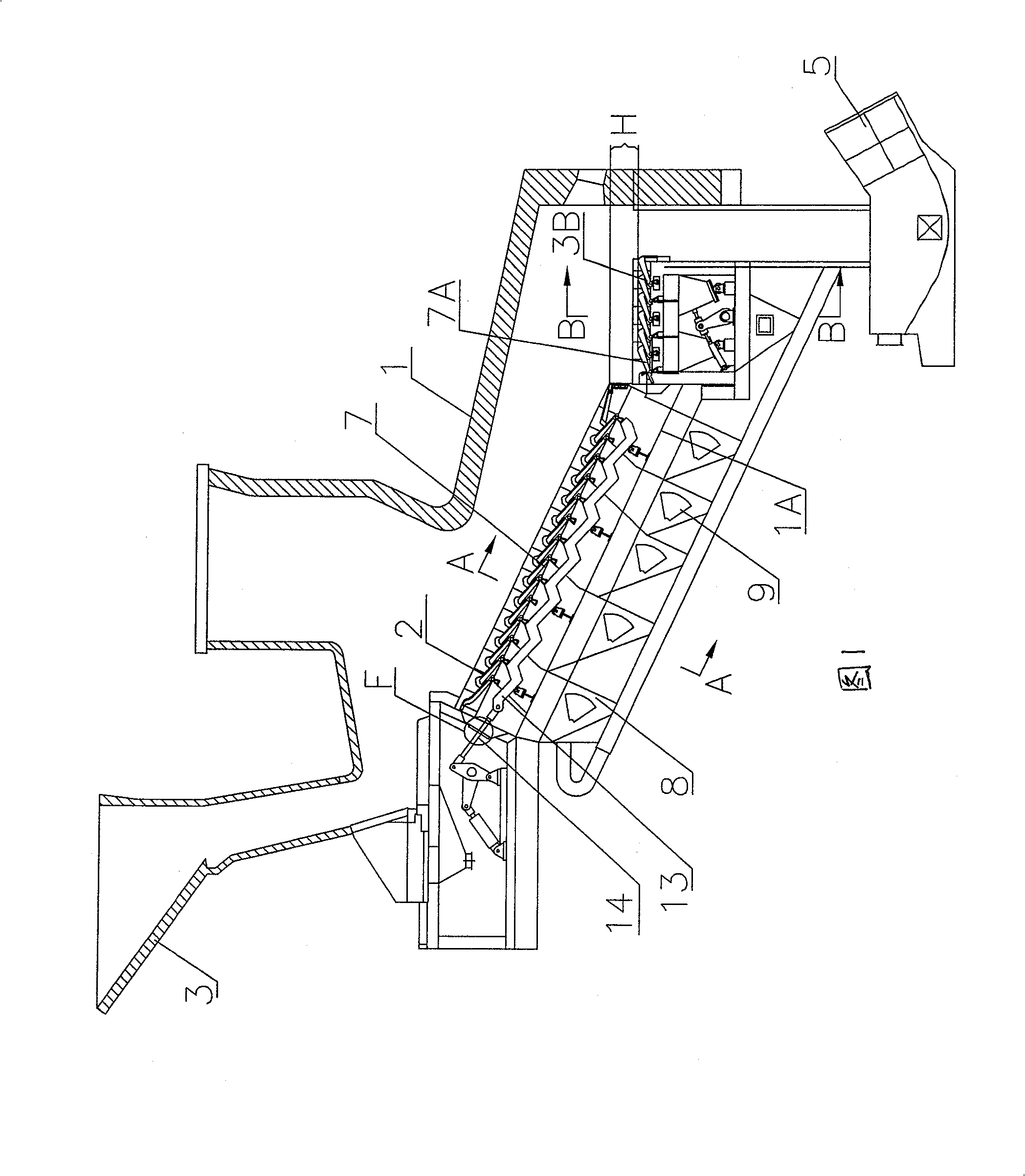

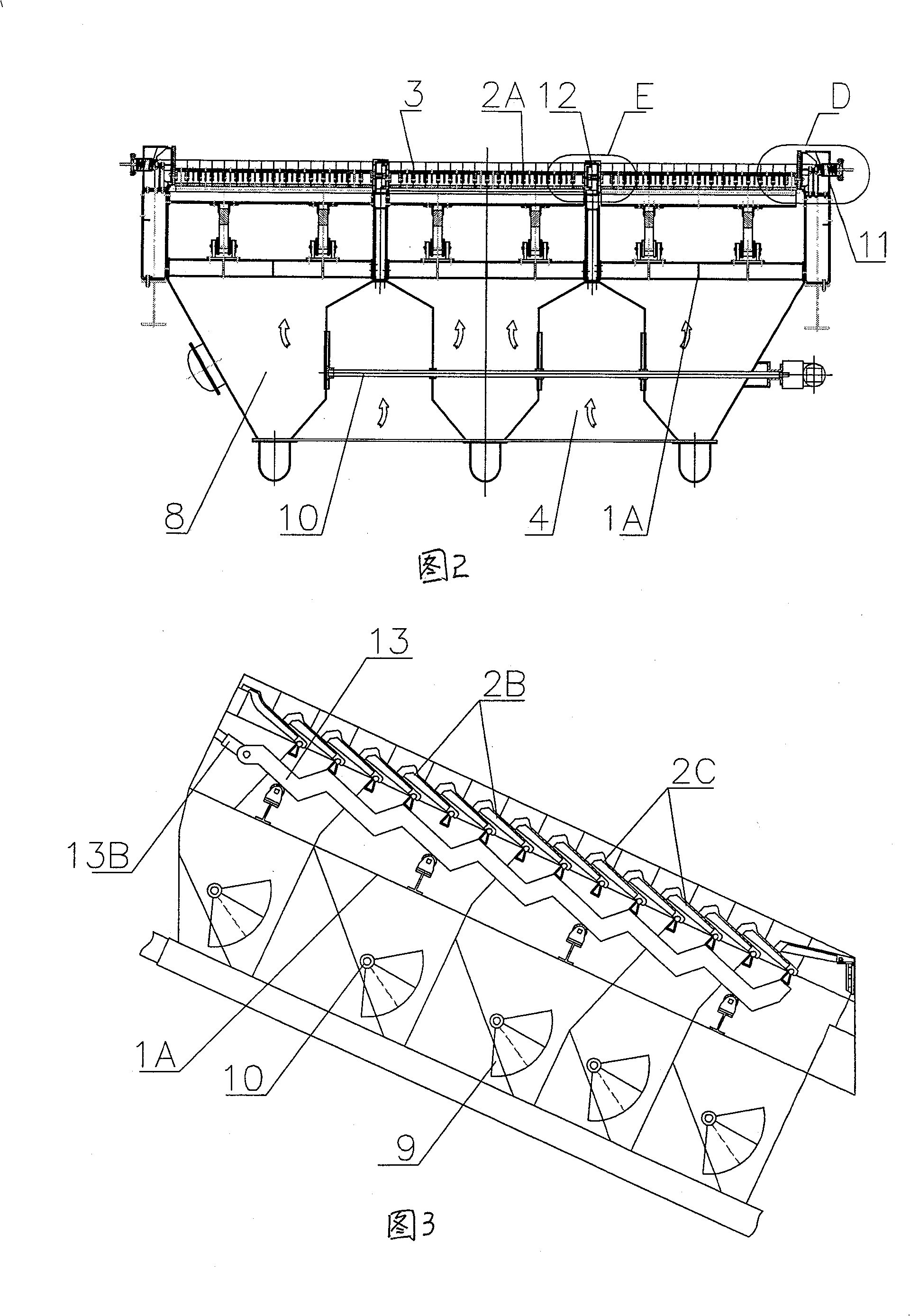

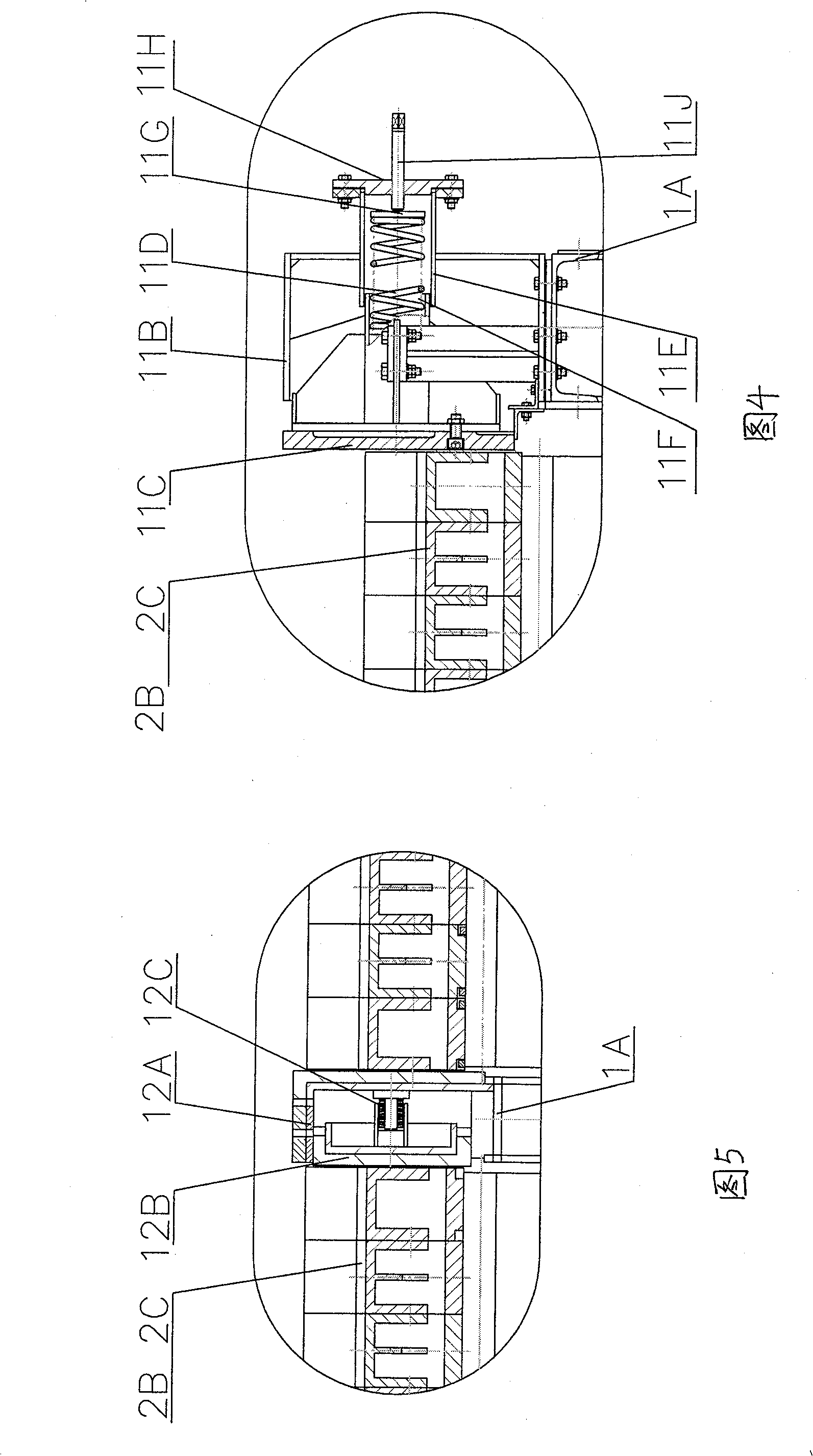

Reciprocating multi-row grate type domestic refuse incinerator

ActiveCN100535520COperational CoordinationPrecise operationIncinerator apparatusCombustionAir volume

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

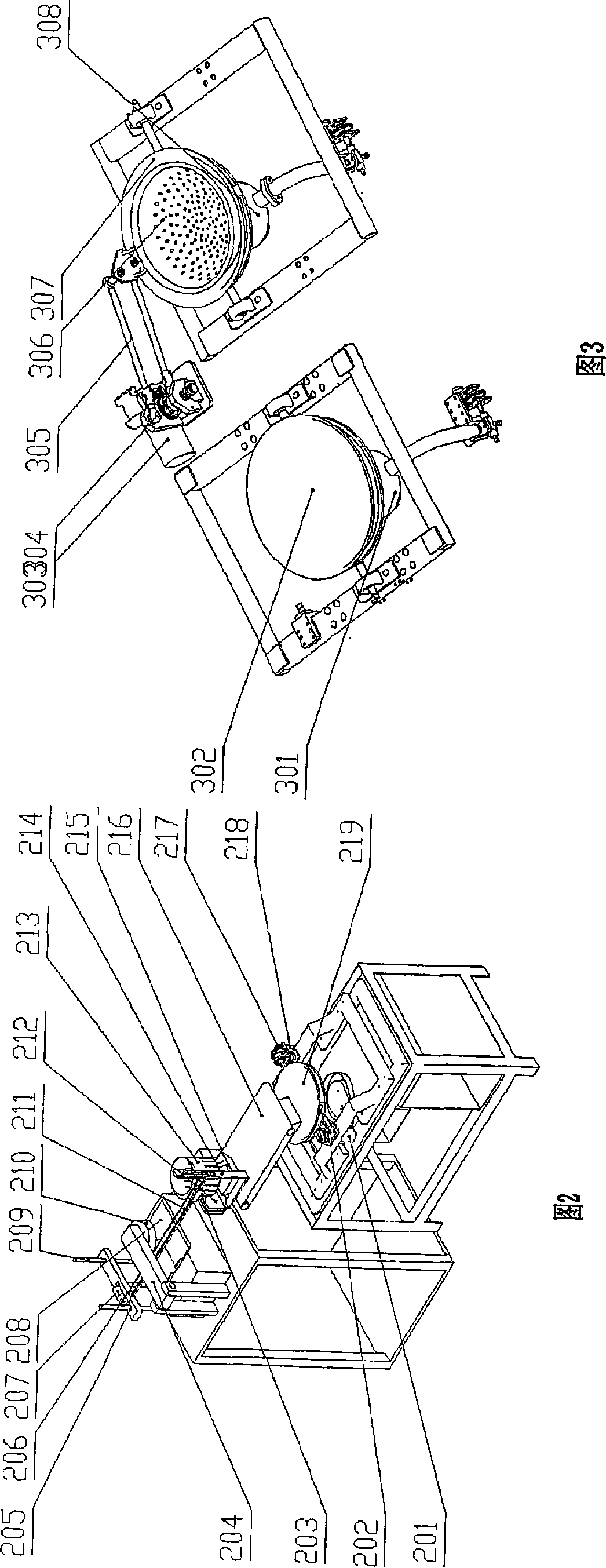

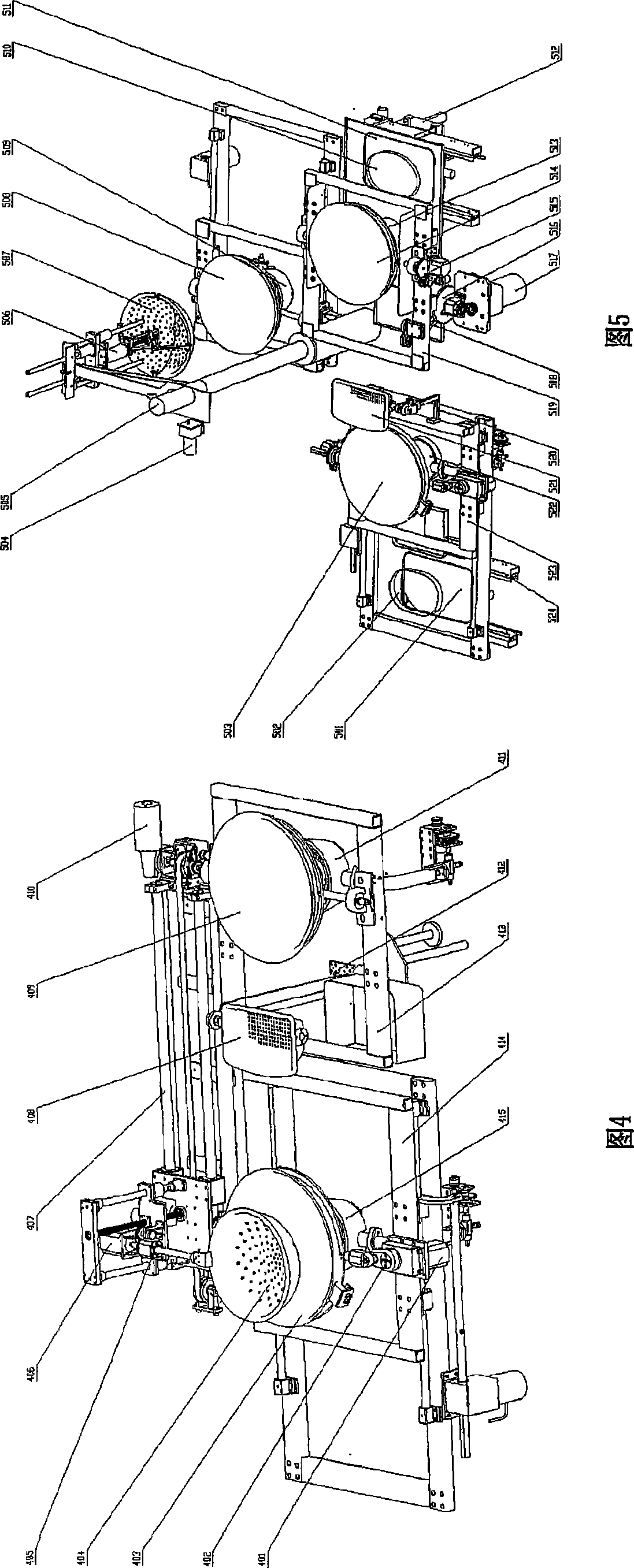

Automatic and semi-automatic cooking system and cooking method

An automatic or a semi-automatic cooking system includes two or more sub-cooking systems (101,104,105). In the cooking system the semi-finished material processed by a sub-cooking system (101) is then continuously processed by another sub-cooking system (104, 105). In the said cooking system, a whole cooking process can be divided into several sub-cooking processes, and the semi-finished materialprocessed in a sub-cooking process is transferred to another sub-cooking process. The said sub-cooking processes are repeated until the whole cooking process is finished.

Owner:AIC ROBOTICS TECH

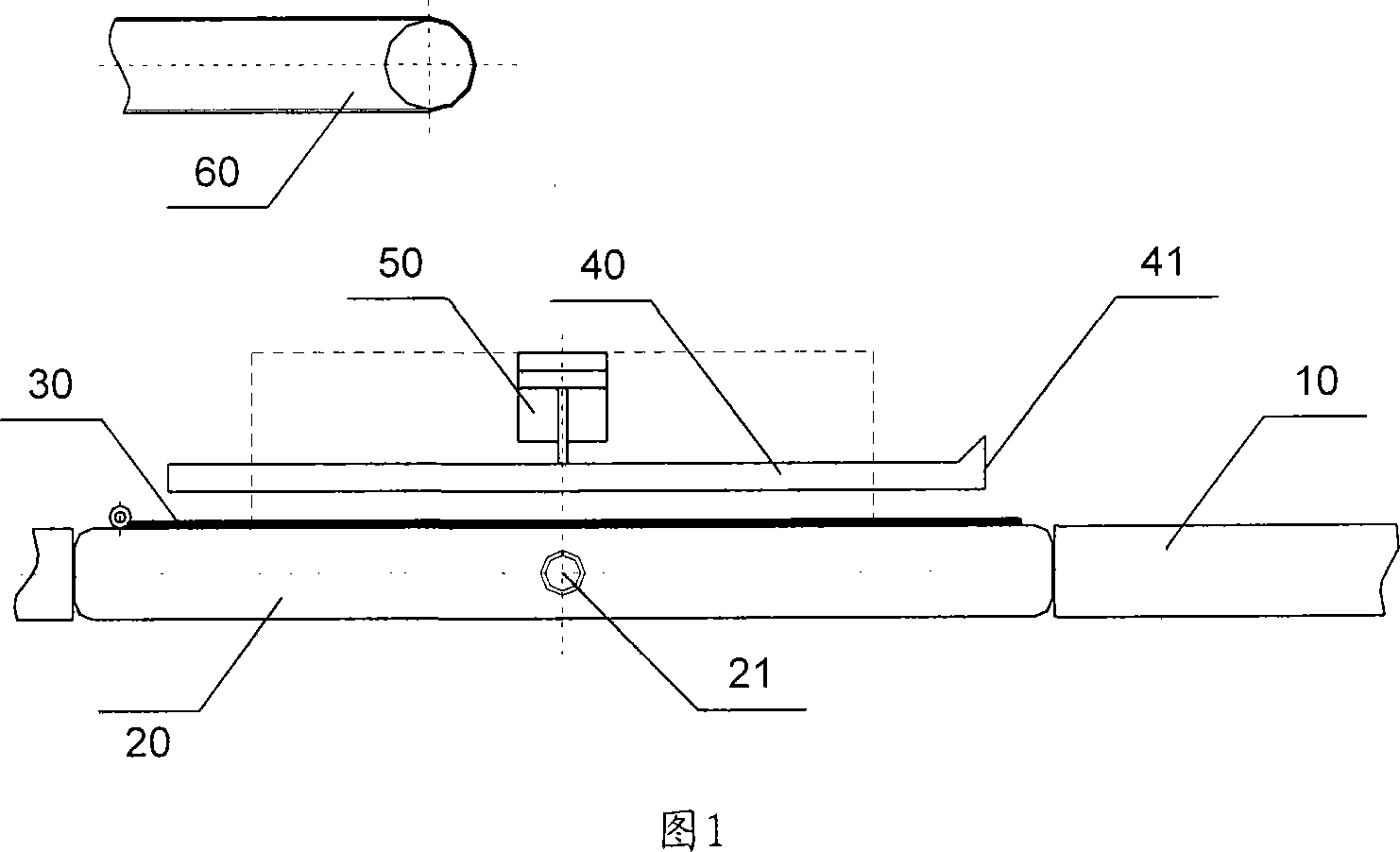

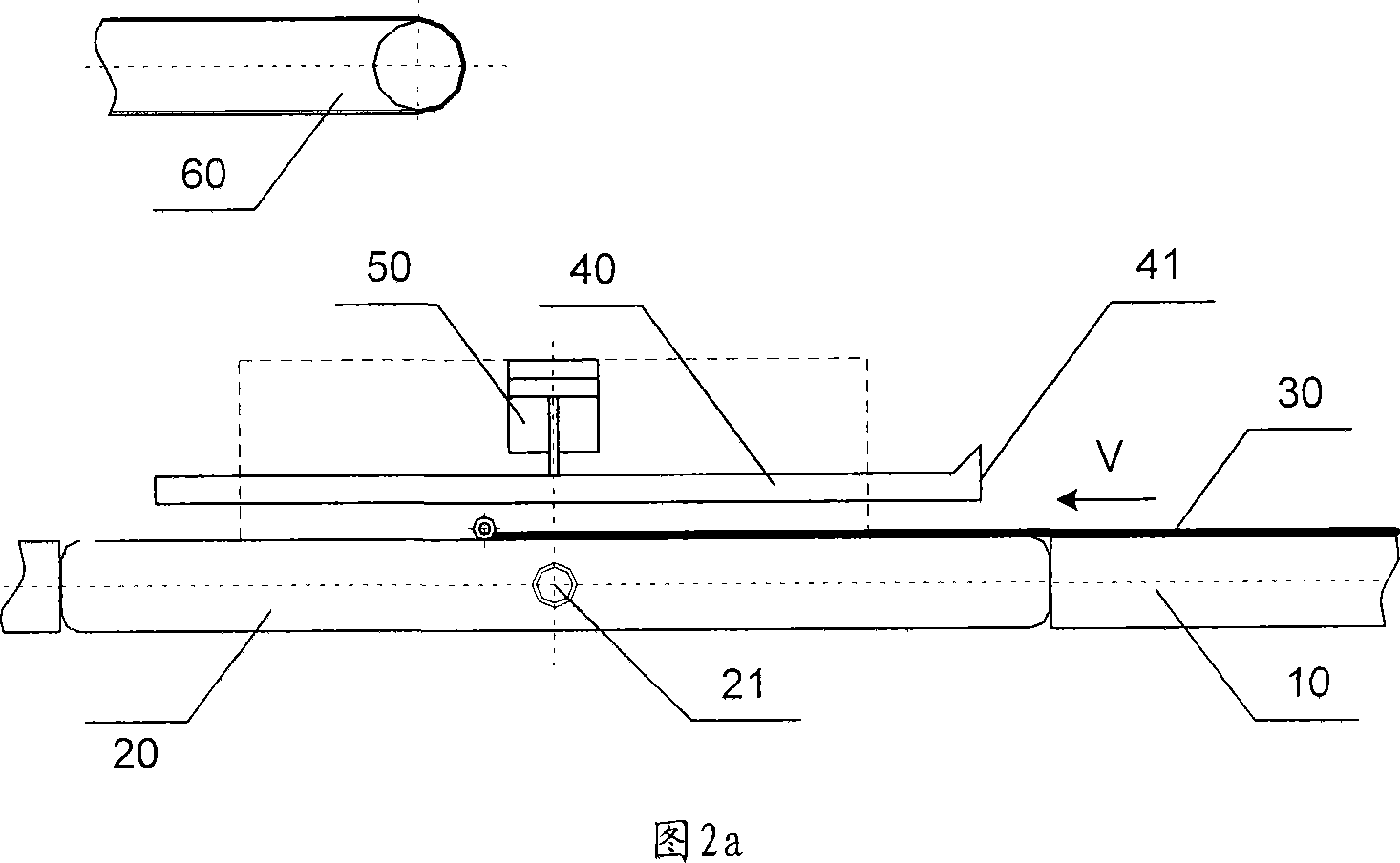

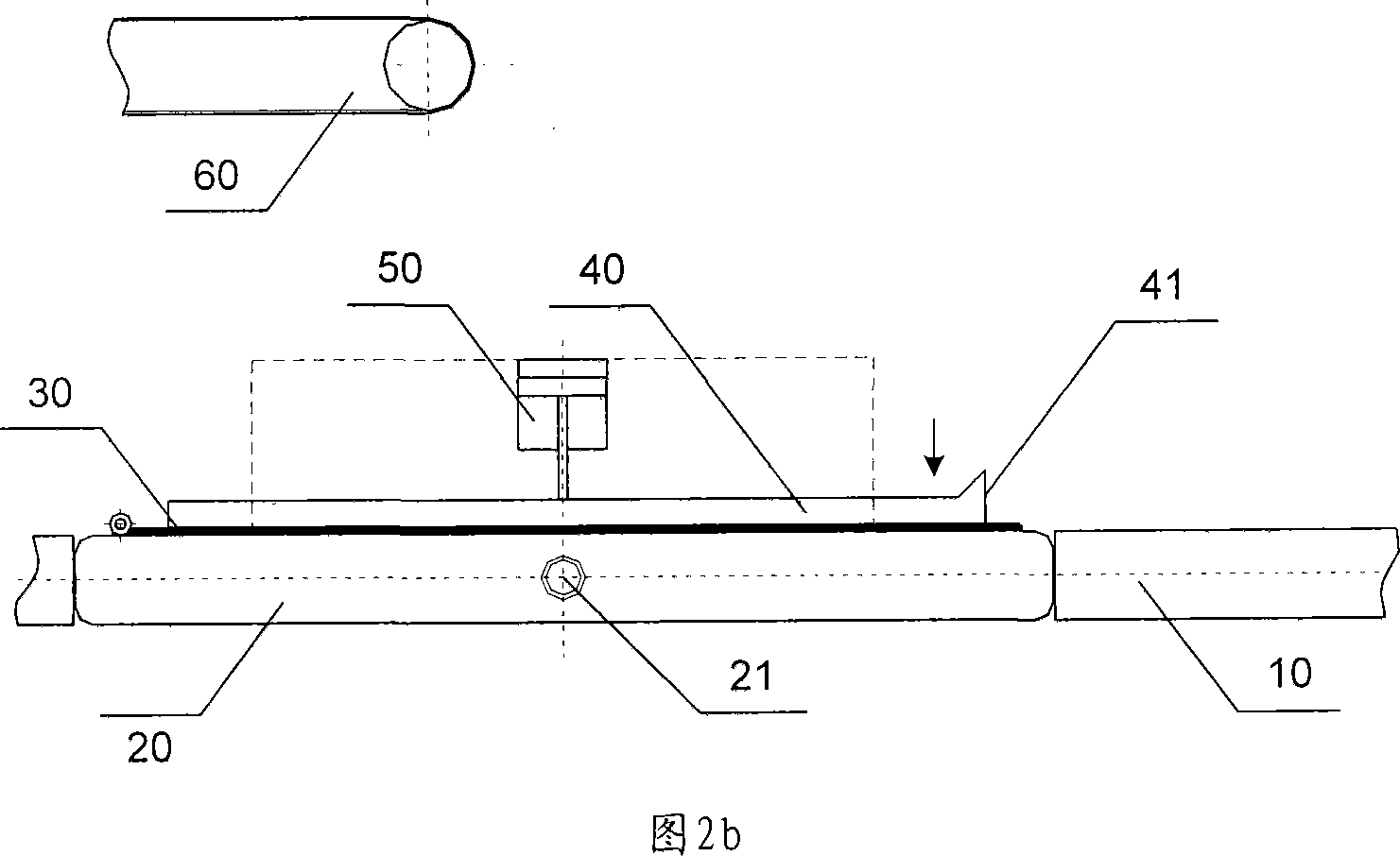

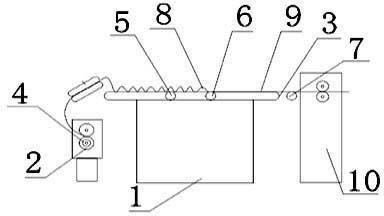

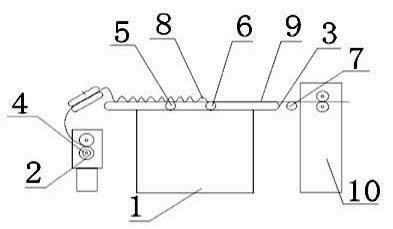

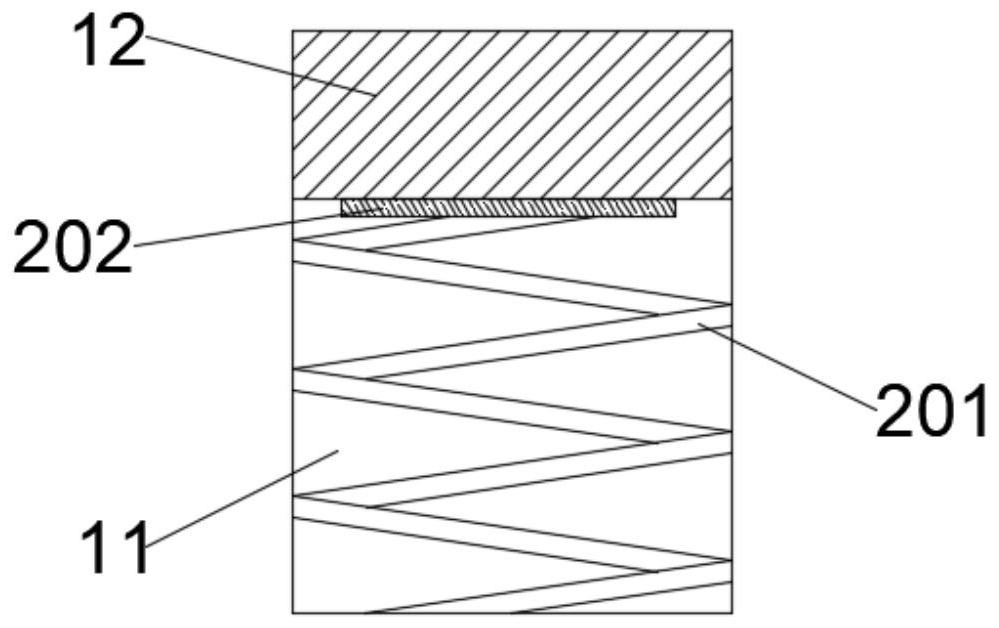

A single-sided machine with precise synchronous carriage device

ActiveCN102275338AAccurate speed measurementOperational CoordinationMechanical working/deformationProduction lineLow speed

The invention discloses a single-side machine with an accurate synchronous transferring device. The single-side machine comprises a stand (1), a feed roller (2) and a slow conveying belt (3), wherein the slow conveying belt (3) is mounted on the stand (1); a coder (4) is mounted on a roller shaft of the feed roller (2) of the single-side machine; a low speed measuring wheel (5) and a high speed measuring wheel (6) are respectively mounted on the stand (1) through a mounting support; the axle of the low speed measuring wheel (5) and the axle of the high speed measuring wheel (6) are located below the slow conveying belt (3); in a normal working state, a paperboard wrinkly paper head (8) always swings back and forth on the high speed measuring wheel (6); the low speed measuring wheel (5) isalways located on the paperboard wrinkly paper section; and a length generator (7) is mounted on the stand (1) and located at the front end of the slow conveying belt (3). The single-side machine disclosed by the invention has the advantages of simple and compact structure and high precision, and can effectively ensure the coordinated operation of the entire production line.

Owner:湖北京山和顺机械有限公司

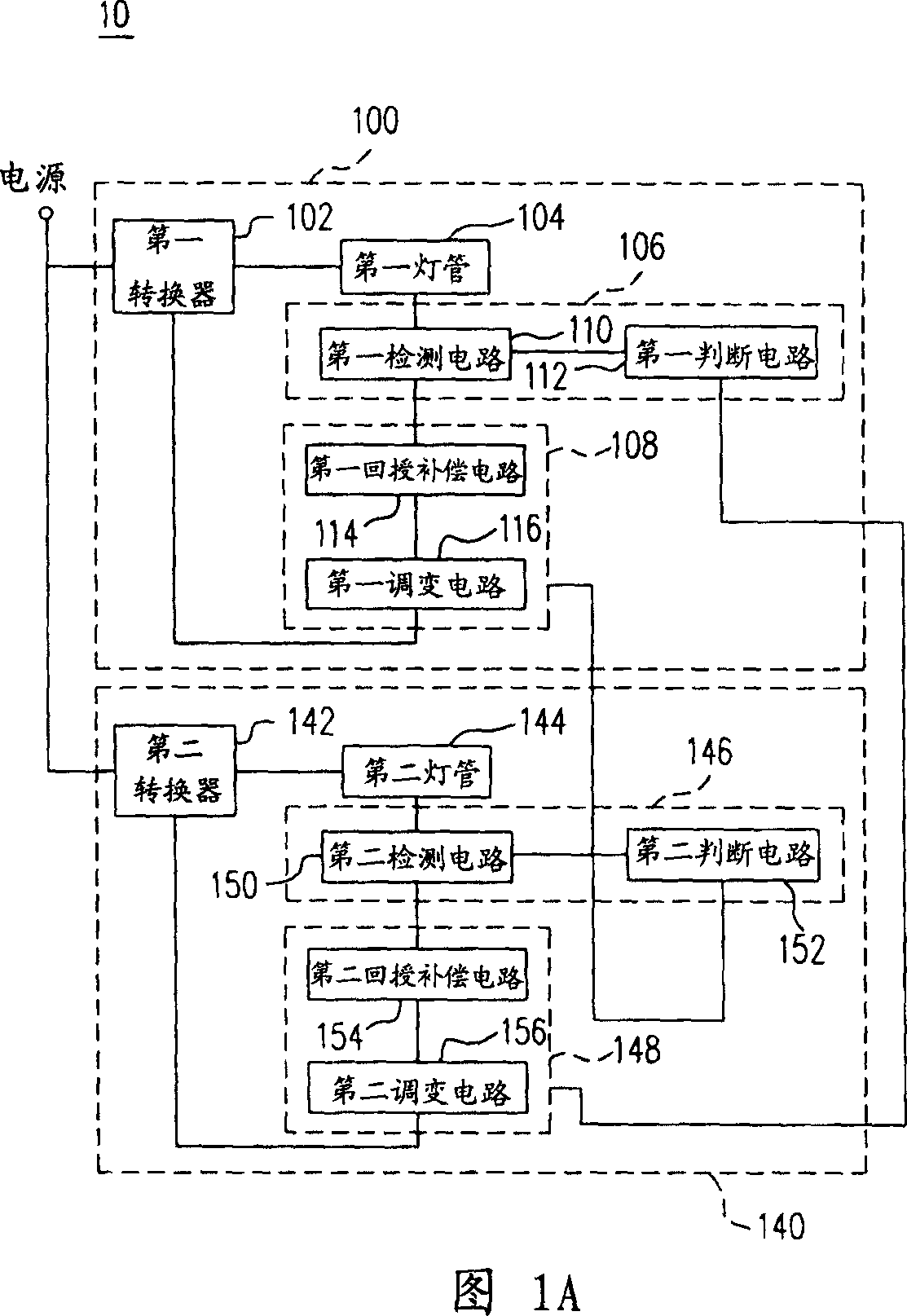

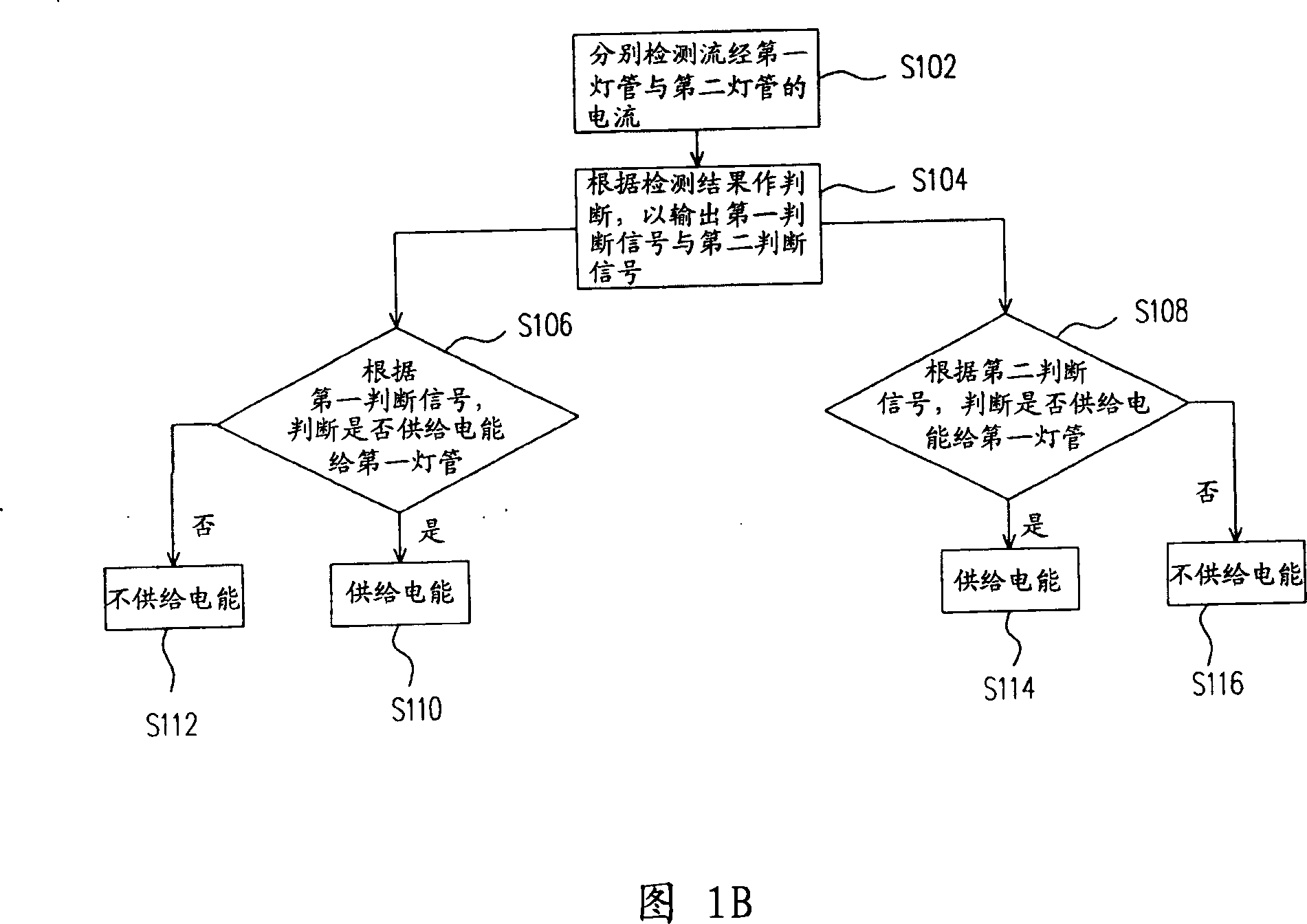

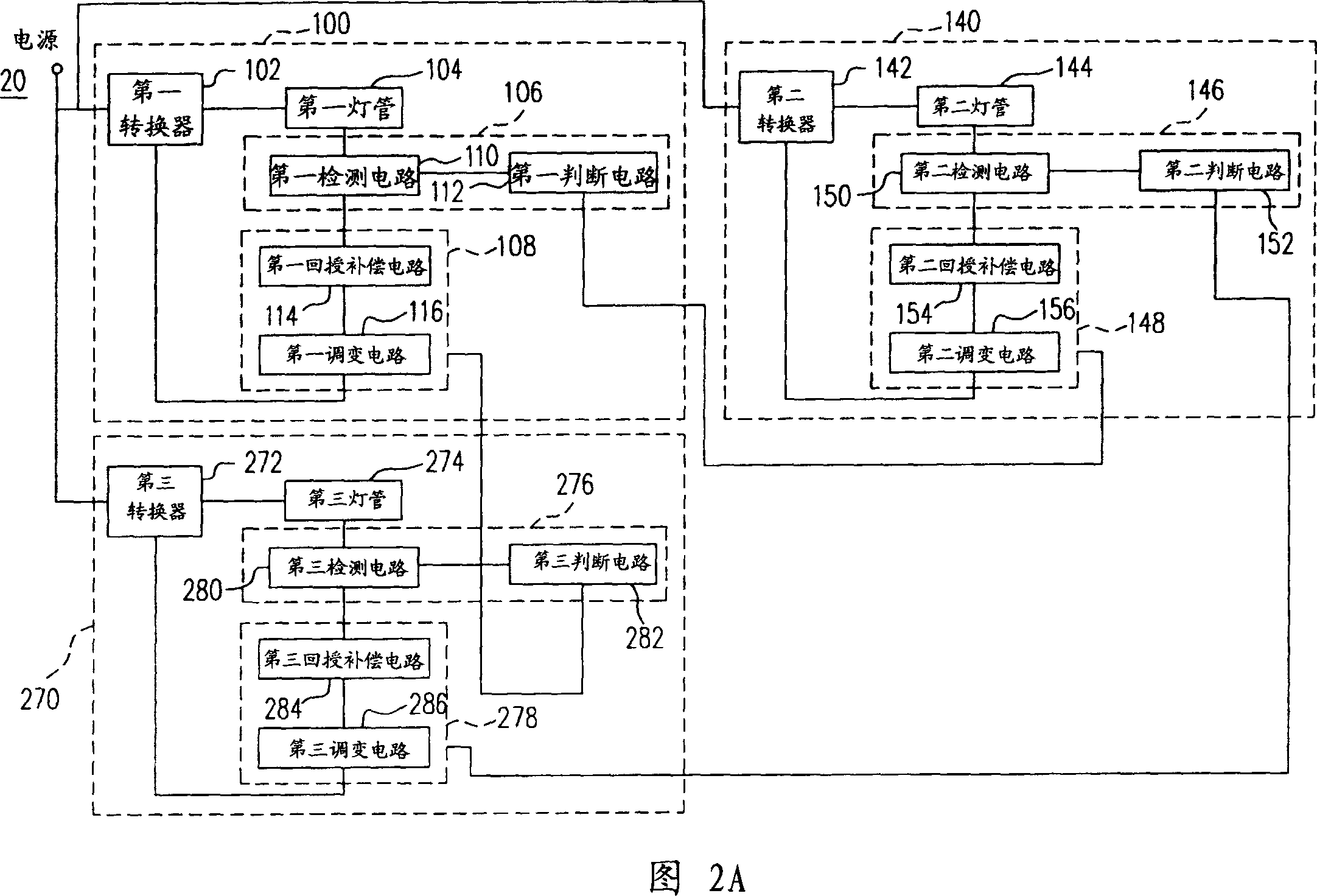

Power supply linking operation device and operation method

InactiveCN101119604AOperational CoordinationImprove electrical performanceElectrical apparatusElectroluminescent light sourcesTransverterControl signal

A lamp duplexing protection apparatus comprises a first lamp module and a second lamp module. The first lamp module outputs a first decision signal according to whether the first lamp operates normally. The second lamp module outputs a second decision signal according to an operating status of the second lamp. The first lamp module determines whether to supply power to the first lamp according to the second decision signal. The second lamp module determines whether to supply power to the second lamp according to the first decision signal.

Owner:BEYOND INNOVATION TECH

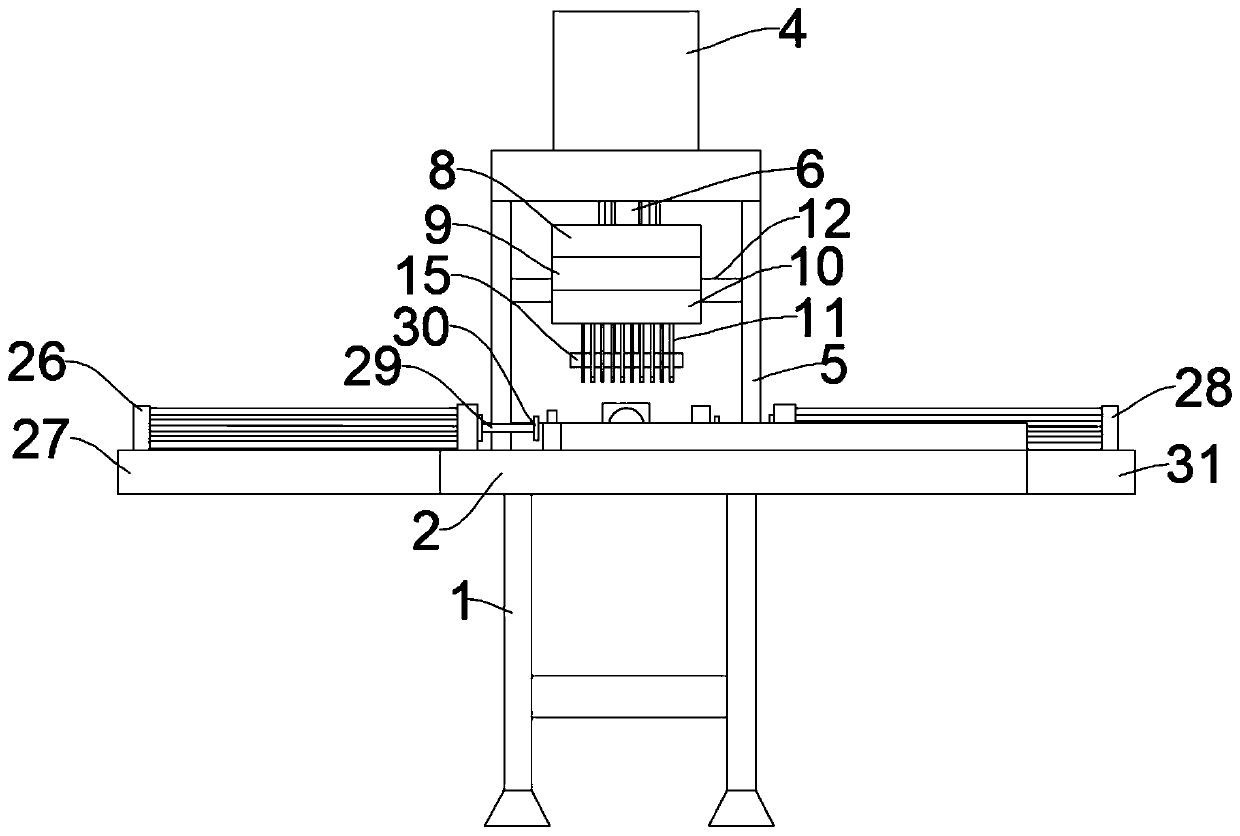

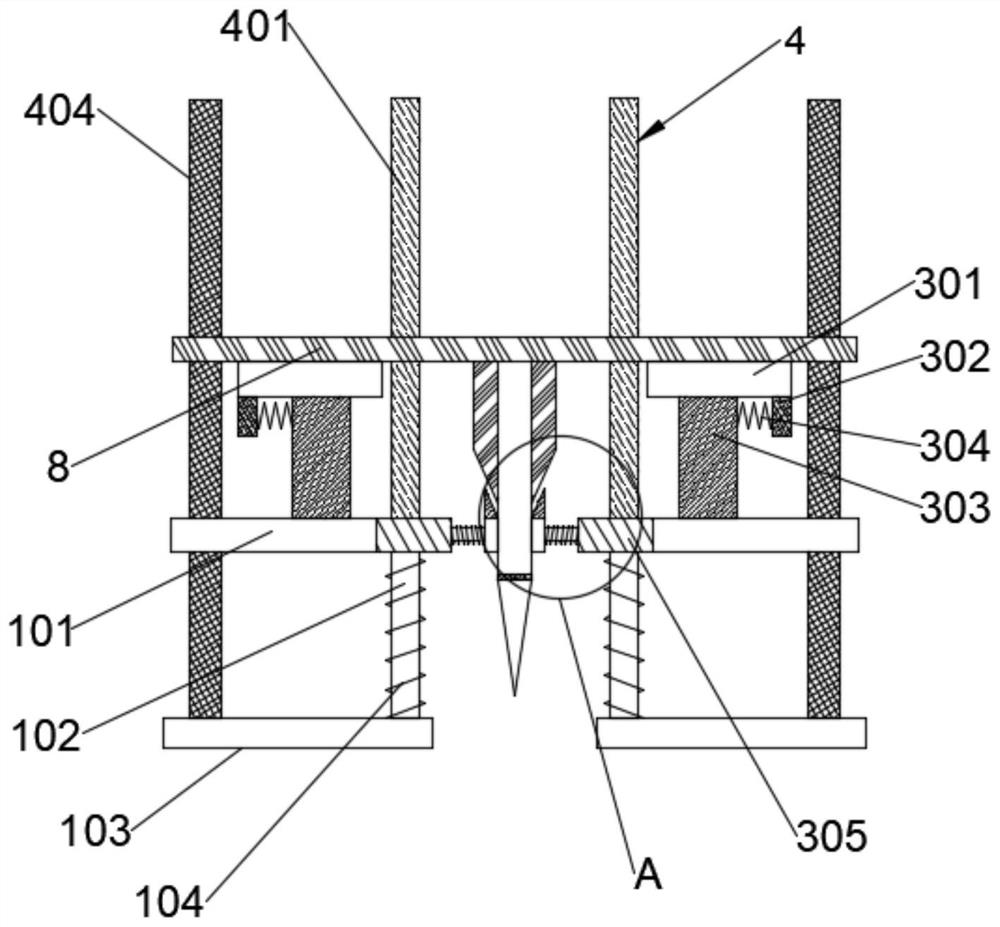

Detection device for mold with detonator shell

The invention relates to a detection device for a mold with a detonator shell, and belongs to the field of civil explosive detonator production. The detection device comprises a detection platform which is arranged horizontally, a detection frame body, a detection channel and a plurality of mechanical arms which are used to push the mold to move in the detection channel, wherein the detection frame body is fixedly arranged on the upper surface of the detection platform, the detection frame body is internally provided with a plurality of vertically arranged detection rods, the bottom ends of the detection rods are provided with sensors, a first air cylinder and a first push rod which is arranged vertically are arranged on the detection frame body, the first push rod is connected with the first cylinder in a driving mode, the bottom of the first push rod is fixedly connected with a fixing device for fixing the detection rods, and the top ends of the plurality of detection rods are fixedly connected with the fixing device; and the detection channel extends to the outside of the detection platform after penetrating through the detection frame body. The detection device for the mold with the detonator shell has the beneficial effect that the automatic detection is carried out through machine instead of manual work, at the same time, the detection speed is accelerated, the productionefficiency of an enterprise is improved, and the cost of the enterprise is reduced.

Owner:GUIZHOU PANJIANG CIVIL EXPLOSIVE +1

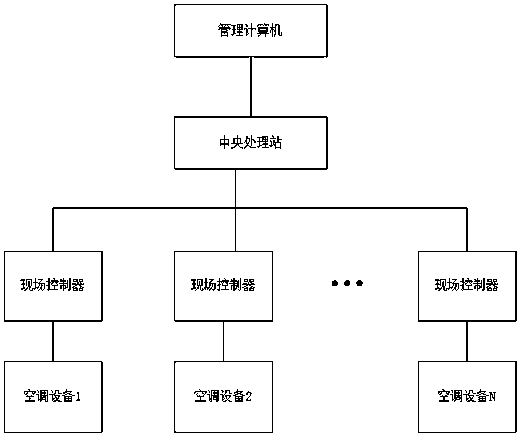

Building air conditioner control system

InactiveCN108105938AOperational CoordinationWill not affect normal operationMechanical apparatusLighting and heating apparatusData operationsDistributed control system

The invention provides a building air conditioner control system. The building air conditioner control system comprises a management computer, a central processing station and more than one scene controllers; the scene controllers replace a monitoring function finished by a central monitoring main machine in the prior art; and the scene controllers are positioned in the scene, receives instructions of the central processing station, automatically references other parameters, and automatically calculates and controls air conditioner equipment. The central processing station dose not burden a lot of data operations and dose not directly participate in control any more, but tends to a management function. The system can realize coordinate operation; and even if once scene controller is brokendown, the normal operation of the whole system cannot be influenced. The building air conditioner control system is a distributed control system; and the system realizes principles of decentralized control and centralized management, and creates conditions for excellent control of the air conditioner system.

Owner:大连前锋科技发展有限公司

Loop type wire drawing machine

PendingCN110756605AReduce the degree of impactGuaranteed timelinessDrawing diesWater tanksWire drawing

The invention provides a loop type wire drawing machine. The loop type wire drawing machine comprises a first machine table, a plurality of second machine tables and a third machine table which are sequentially arranged from a wire inlet end of the drawing machine to a wire outlet end of the drawing machine, a water tank and an electric control cabinet, wherein the water tank is arranged at one end of the drawing machine, and the electric control cabinet is arranged on the other end of the drawing machine; the wire inlet end of the drawing machine and the wire outlet end of the drawing machineare both provided with herringbone rollers; a mold box, a hanging bracket device, a wire pulling device and a first winding drum are arranged on the first machine table; mold boxes, second winding drums and guide wheel devices are arranged on the second machine tables; and a mold box and a second winding drum are arranged on the third machine table. According to the loop type wire drawing machine, the multi-stage winding drums and the mold boxes are arranged, and the mold boxes are capable of lubricating and cooling metal wires, so that the drawing force of the metal wires between every adjacent winding drums is reduced, the drawing speed is increased, the drawing quality is improved, and the production efficiency is improved.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

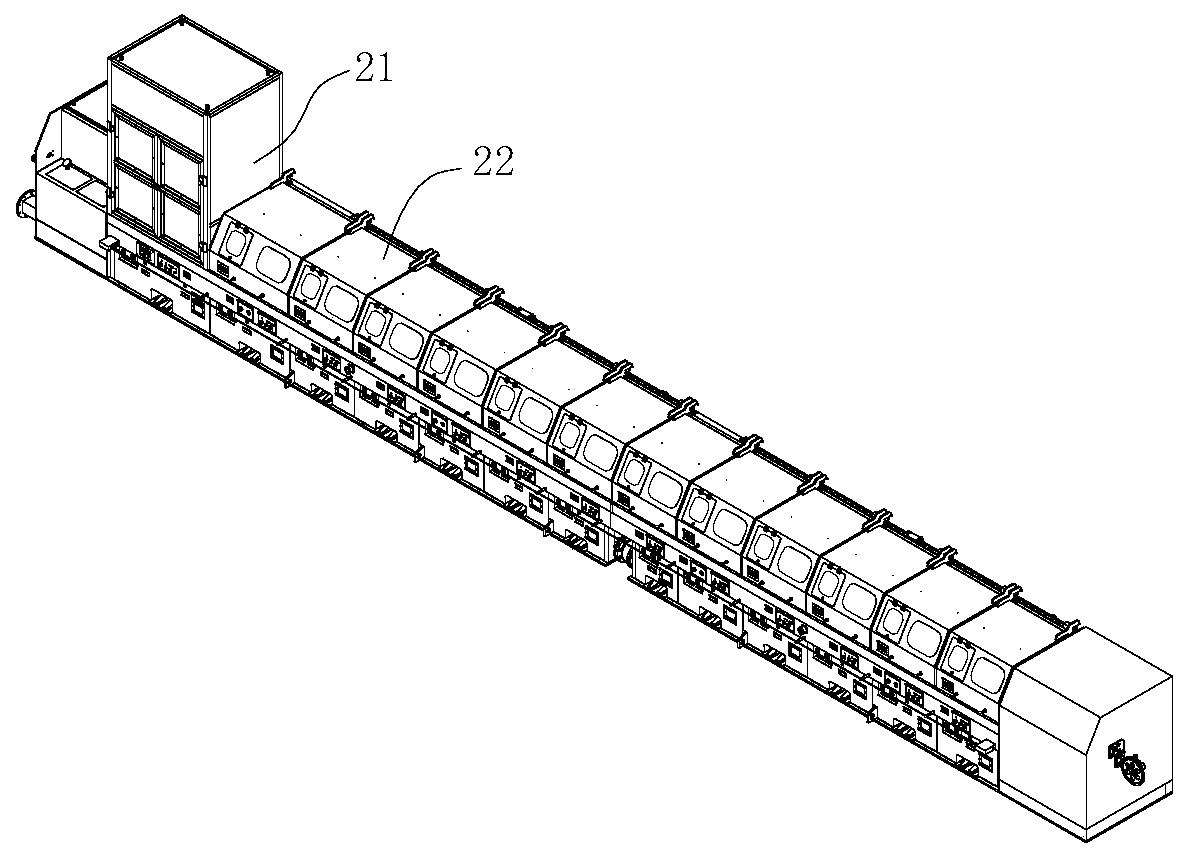

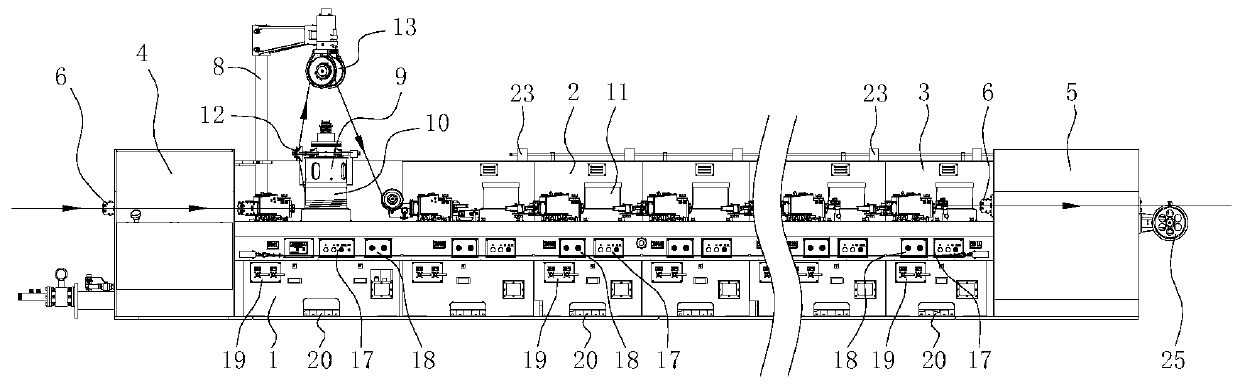

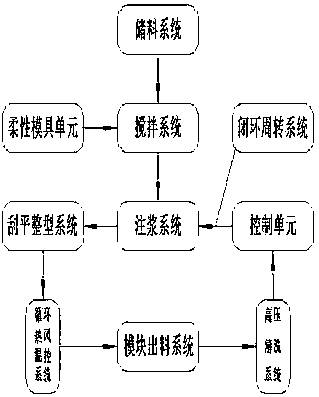

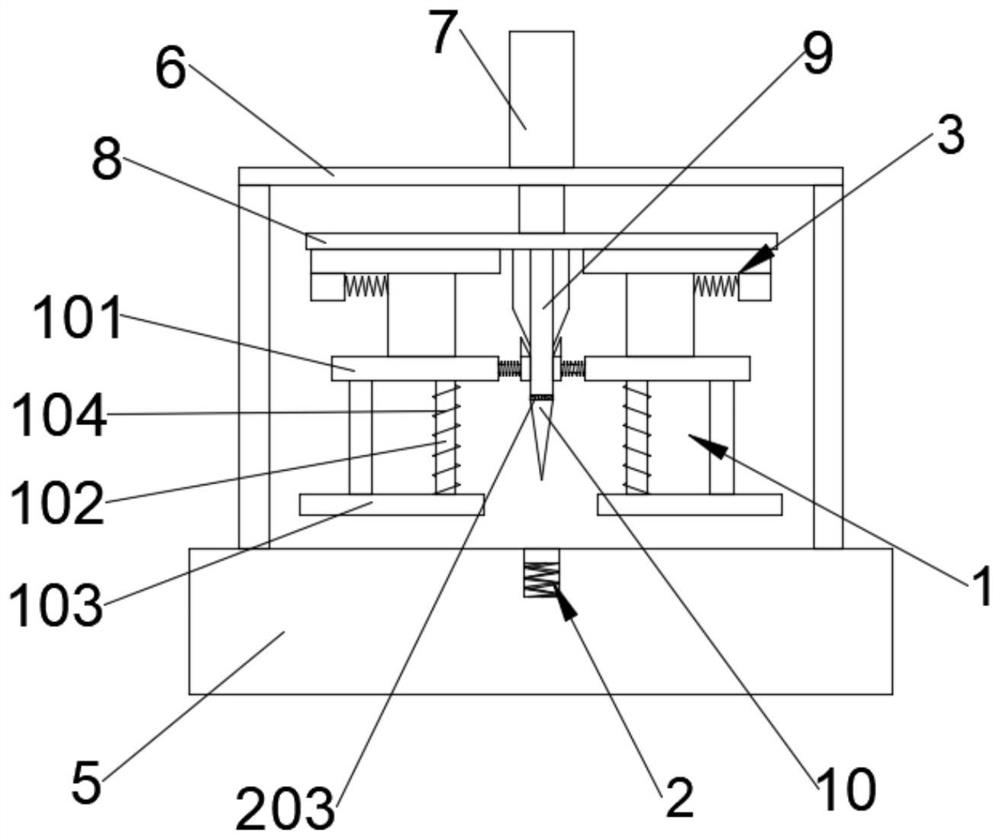

Automatic production technology of fabricated building blocks

PendingCN109693307AOperational CoordinationEfficient cooperationCeramic shaping plantsFeeding arrangmentsClosed loopHigh pressure

The invention mainly relates to an automatic production technology of fabricated building blocks. The automatic production technology is mainly used for the production and manufacture of fabricated building blocks for non-load bearing walls in the construction industry. The automatic production technology includes the automatic production and processing of gypsum building blocks, concrete buildingblocks and environment-friendly material building blocks. The automatic production technology is mainly composed of a material storage system, a mixing system, a grouting system, a closed loop turnover system, a scraping and leveling system, a circulating hot air temperature control system, a high pressure cleaning system, a flexible mold unit, a molded block discharging system and a control unit. The applied fabricated building block production technology adopts a full-automatic production and transportation system and adopts a movable flexible mold unit or a plurality of mold groups, and material grouting is carried out at an grouting station of a grouting system through the movement of the movable flexible mold unit or the mold groups so as to reduce manpower operation; and an accuratemechanical control system is adopted, a sensing control device is utilized to ensure linkage operation of parts so as to realize full operation and implementation until finished product discharging is completed, the problems that a large great of manual labor and turnover cycles are solved, and resource waste is less.

Owner:王海峰

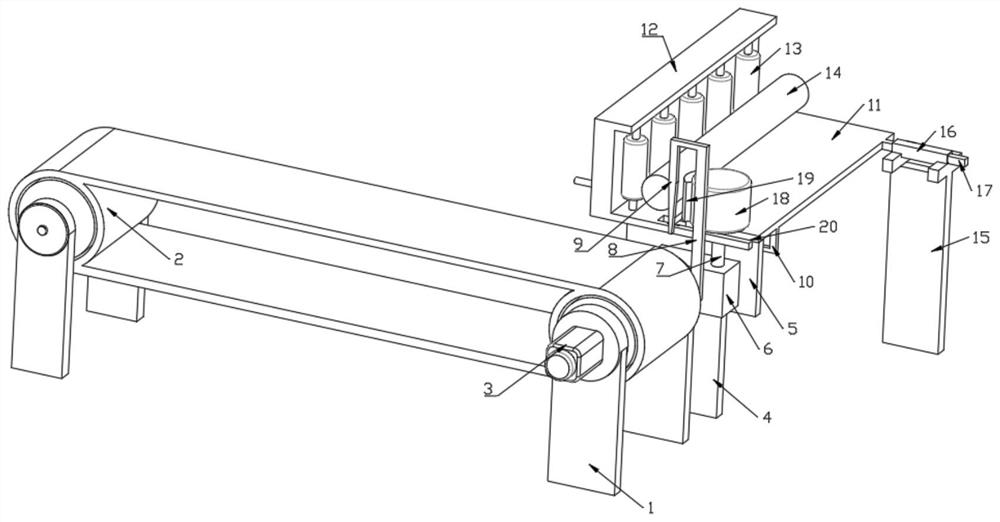

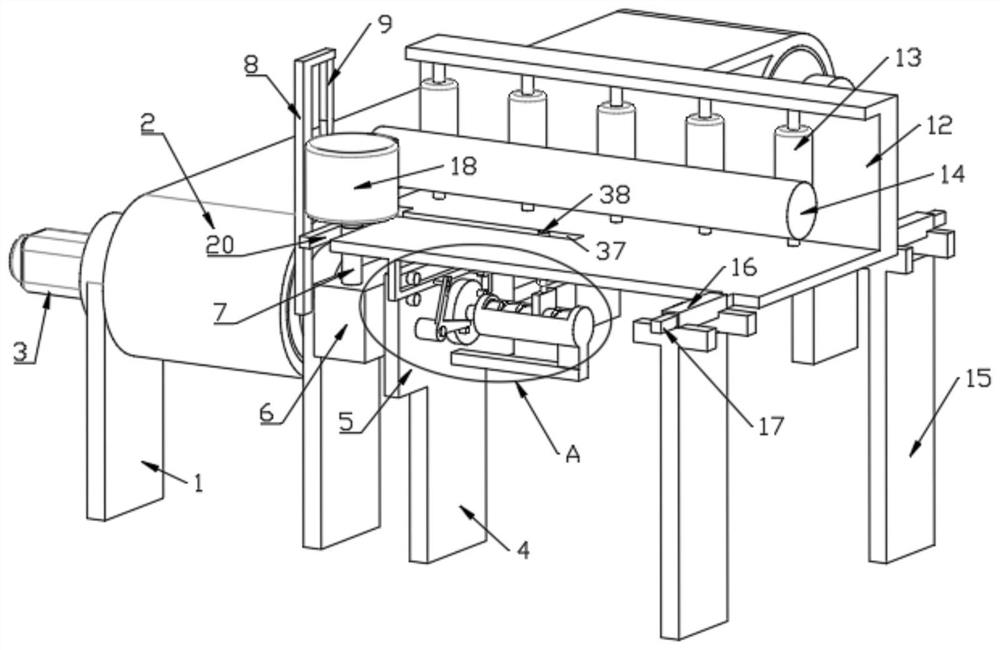

Pressing and cutting integrated melt-blown cloth splitting machine

InactiveCN113059600AEasy to fixGuaranteed accuracySevering textilesMetal working apparatusStructural engineeringKnife holder

The embodiment of the invention discloses a pressing and cutting integrated melt-blown cloth splitting machine, which comprises a base and a fixed plate arranged on the base in parallel; the fixed plate is fixed to the base through a support; a driving air cylinder is arranged on the fixed plate; an output end of the driving air cylinder vertically penetrates through the fixed plate downwards and is connected with a driving plate; a cutter frame is arranged in the center of the bottom end of the driving plate; a cutter is vertically connected to the bottom of the cutter frame; pressing components are arranged at the two ends of the driving plate respectively; the pressing components on the two sides are symmetrically arranged on the two sides of the cutter; each pressing component comprises a pressing base plate horizontally connected with the driving plate; a pressing rod vertically penetrates through the pressing base plate; the lower end of the pressing rod is connected with a horizontal pressing plate; a pressing buffer spring is arranged between the driving plate and the pressing plate; and the pressing buffer spring is sleeved on the outside of the pressing rod. The splitting accuracy of melt-blown cloth can be well guaranteed, and the finished product quality of the melt-blown cloth is improved.

Owner:安徽伟源兴盛实业有限公司

Cutting equipment for roll-shaped non-woven fabric

PendingCN112663319AIncrease linkageImprove coordinationSevering textilesMetal working apparatusEngineeringStructural engineering

The invention discloses cutting equipment for roll-shaped non-woven fabric. The cutting equipment comprises a conveying platform; the roll-shaped non-woven fabric is arranged above the conveying platform; a concave plate is fixedly connected to one side of the conveying platform; a first strip-shaped opening is formed in one end of the conveying platform; the first strip-shaped opening and the concave plate are provided with a conveying mechanism for conveying the roll-shaped non-woven fabric in a matched mode; a functional plate is arranged below the conveying platform; the side wall of the functional plate is fixedly connected with a box body; the box body is provided with a linkage mechanism in a matched mode; the lower end of the functional plate is fixedly connected with a first supporting plate; the side wall of the functional plate is rotationally connected with a disc; and the disc is provided with a reciprocating mechanism enabling the conveying platform to reciprocate in a matched mode. The cutting equipment is reasonable in structure, can quickly and effectively cut roll-shaped non-woven fabric, and can quickly suck and discharge dust generated on the conveying platform.

Owner:郑一丁

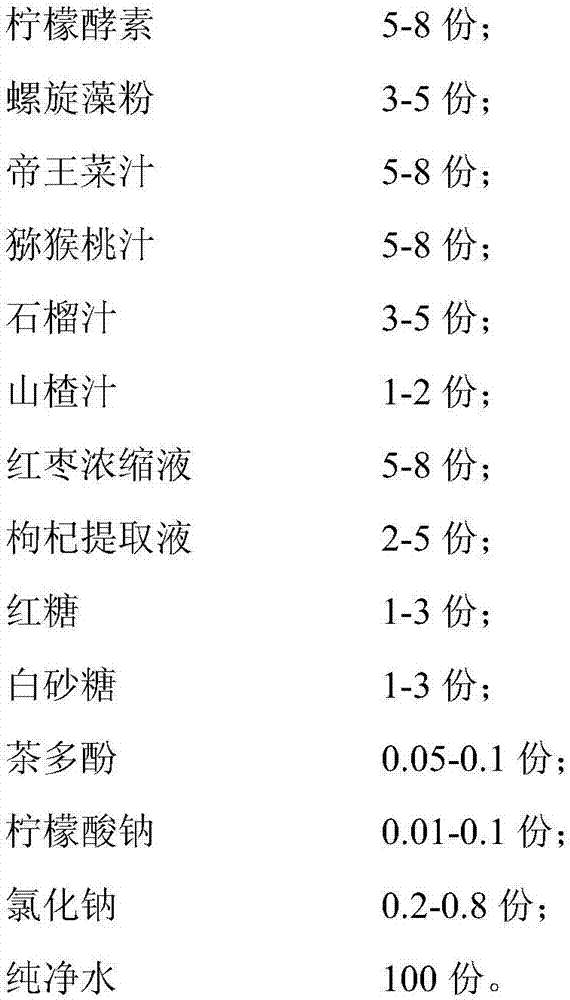

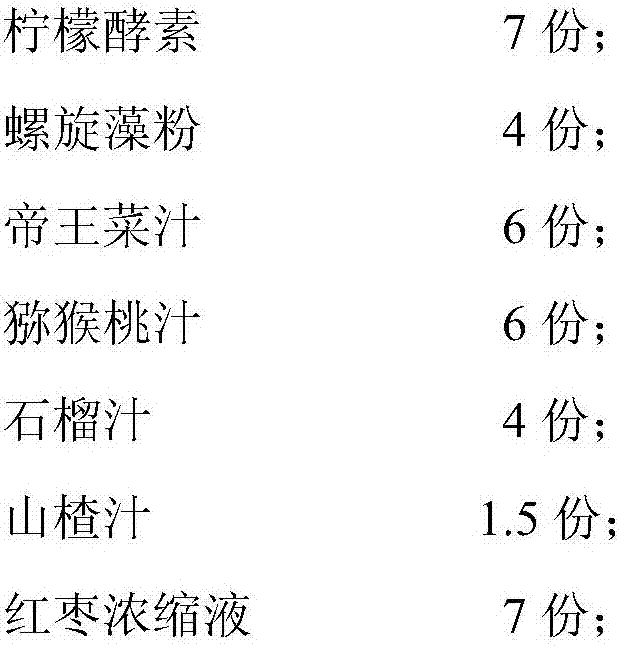

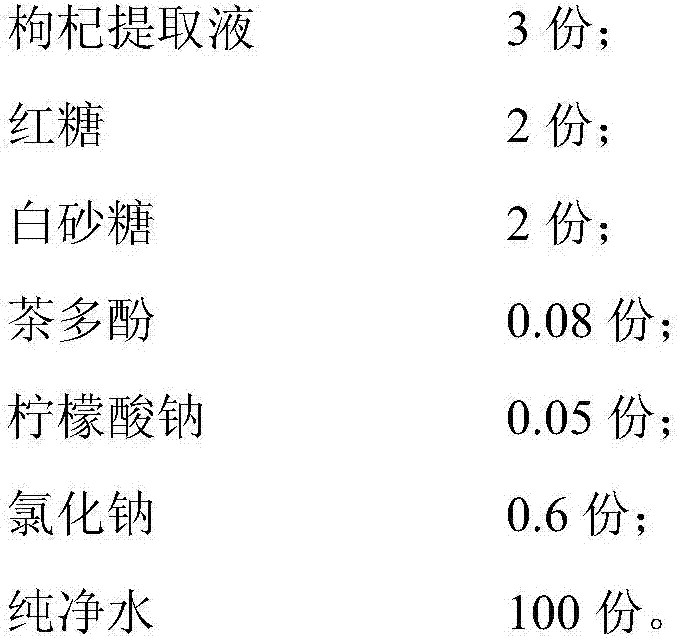

Organic lemon enzyme health-care nutrient solution and preparation method thereof

InactiveCN106993808AAnti-fatigueImprove stabilityFood ingredient functionsBiotechnologyPhenolic content in tea

The invention relates to health-care nutrient solution and specially discloses health-care nutrient solution containing lemon enzyme. The nutrient solution is prepared from the following ingredients in parts by weight: 5 to 8 parts of lemon enzyme, 3 to 5 parts of spiral seaweed powder, 5 to 8 parts of corchorus olitorius herb juice, 5 to 8 parts of kiwi fruit juice, 3 to 5 parts of grenadine juice, 1 to 2 parts of hawthorn fruit juice, 5 to 8 parts of red date concentrated solution, 2 to 5 parts of fructus lycii extracting solution, 1 to 3 parts of brown sugar, 1 to 3 parts of white granulated sugar, 0.05 to 0.1 part of tea polyphenol, 0.01 to 0.1 part of sodium citrate, 0.2 to 0.8 part of sodium chloride and 100 parts of purified water. The invention further discloses a preparation method of the nutrient solution. The organic lemon enzyme health-care nutrient solution disclosed by the invention contains full and balanced nutrients, contains rich active ingredients, can improve the absorption and utilization rate of a human body to nutrients and improves functional immunity of the human body. Furthermore, the organic lemon enzyme health-care nutrient solution disclosed by the invention has good stability.

Owner:广东盆地一号生物产业有限公司 +1

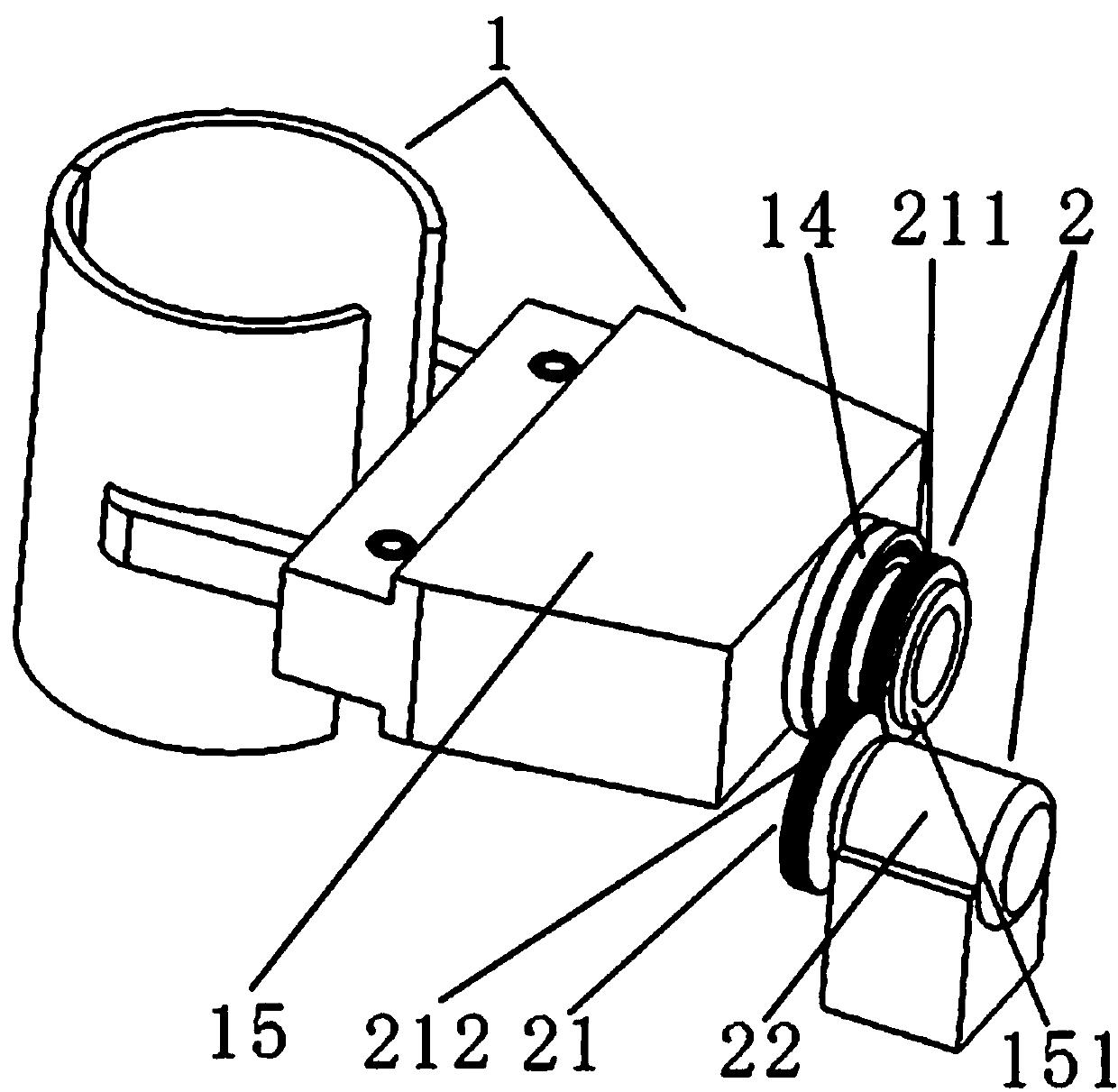

Water lifting auxiliary machine

The invention discloses a water lifting auxiliary machine, and relates to the field of daily life. The water lifting auxiliary machine comprises a clamping device, a lifting device, an overturning device and a traveling device, wherein the clamping device is coupled to the lifting device, the turnover device is connected to the clamping device, the turnover device is coupled with the lifting device, the clamping device comprises a connecting rod mechanism, a crank sliding block mechanism and a driving motor, the connecting rod mechanism is connected to the crank sliding block mechanism, the crank sliding block mechanism is arranged on the driving motor, the clamping device, the lifting device and the overturning device are arranged on the traveling device to facilitate the realization of clamping, lifting and turning function, and the installation function of the barreled water on the water dispenser is finally realized. The labor intensity is low, and the labor is saved and convenient.

Owner:ZHEJIANG UNIV OF TECH

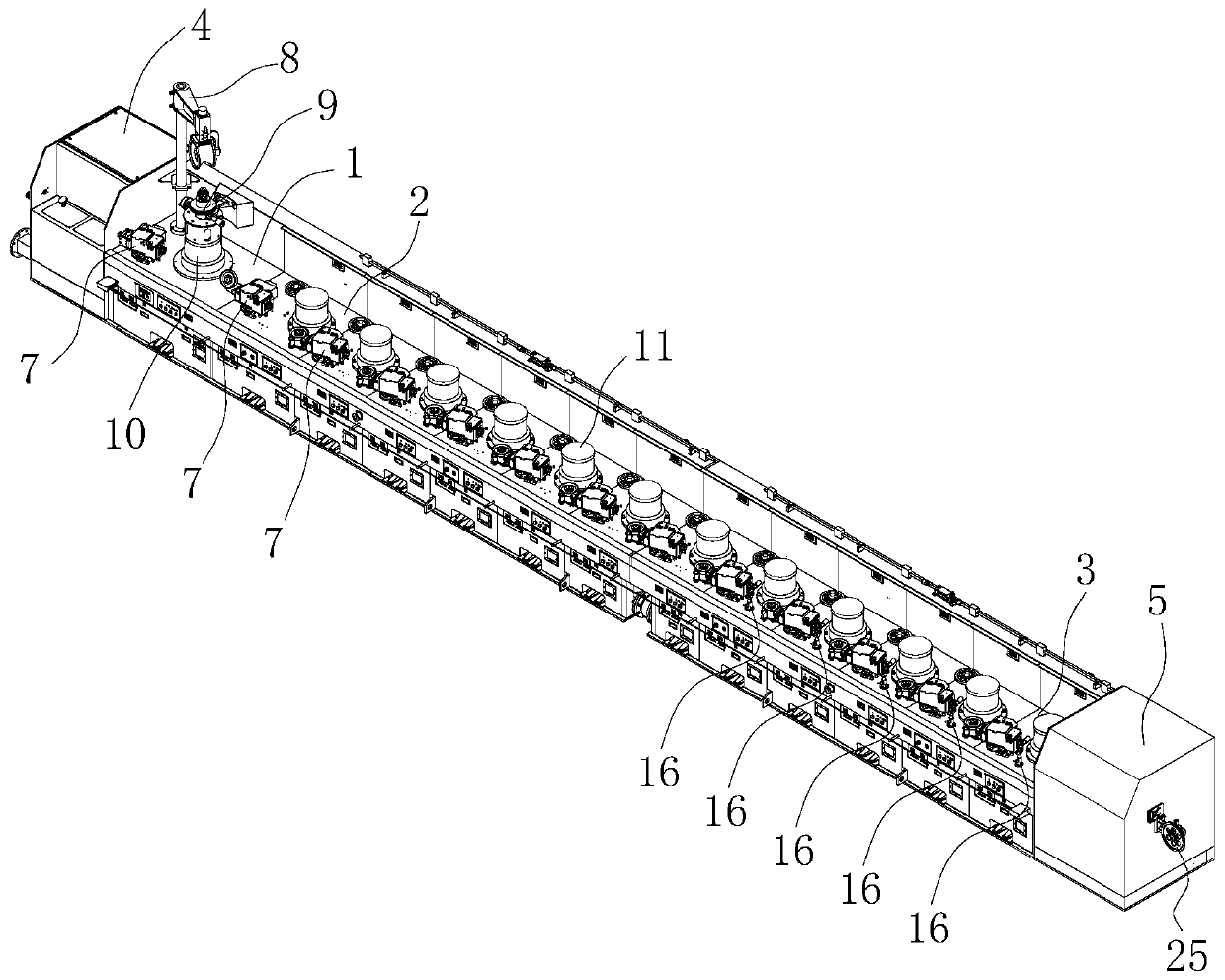

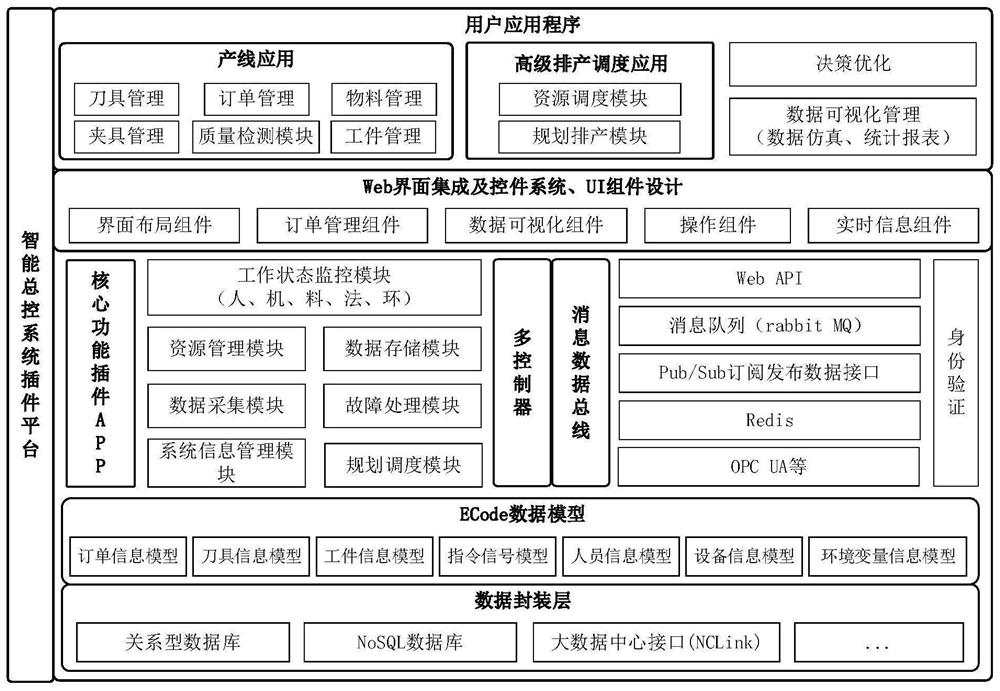

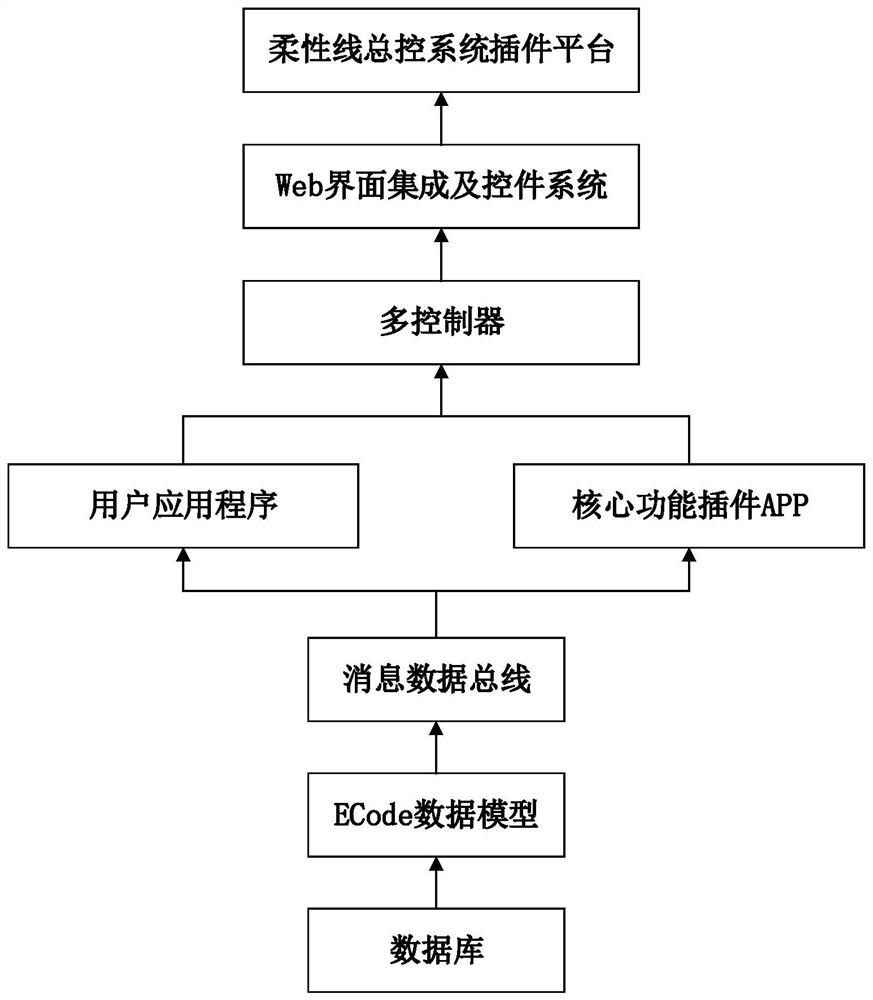

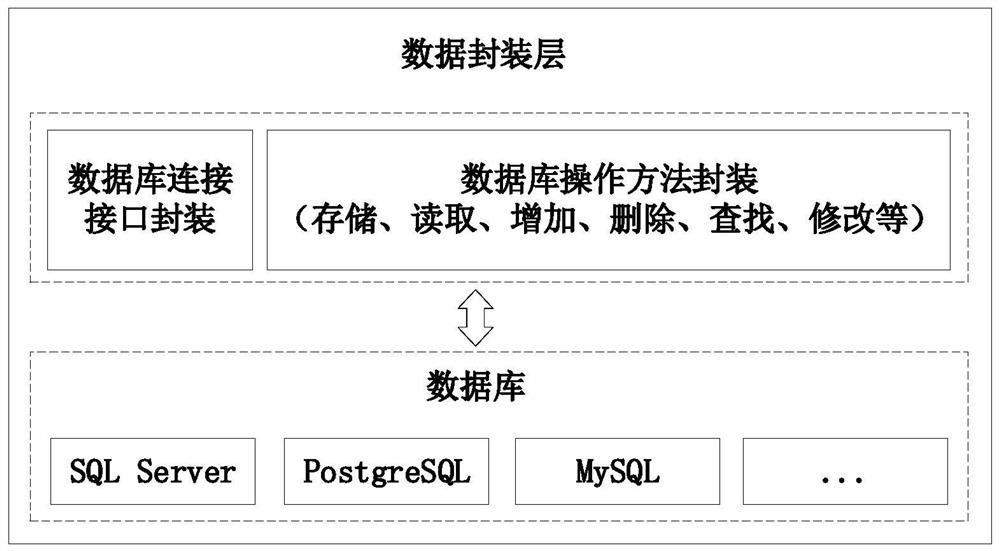

Flexible production line control system platform based on micro-service architecture

ActiveCN112965446ASolve scalabilitySolve problems such as maintenance difficultiesTotal factory controlProgramme total factory controlCore functionControl system

The invention discloses a flexible production line control system platform based on a micro-service architecture, and belongs to the technical field of integration and platformization of flexible manufacturing control systems. The flexible production line control system platform comprises an expansion layer, a presentation layer, an application layer and a data layer; the application layer comprises a core function unit and a multi-controller unit; the data layer comprises an ECode data model composed of all data related to a flexible production line; the extension layer is used for loading, unloading, modifying or deleting a functional module written based on the ECode data model so as to realize extension of a new function on the function of the application layer; the multi-controller unit comprises a plurality of sub-controllers and is used for calling at least one function module in the expansion layer or the core function unit according to an execution instruction, so that the function modules are independent or mutually coordinated and matched to analyze and process the execution instruction until the execution is completed; and the presentation layer is used for realizing function display of the core function unit and the expansion layer. The system platform provided by the invention has high flexibility and expandability.

Owner:HUAZHONG UNIV OF SCI & TECH

Cutter belt adjustment system of vertical-cutter-type high-speed digital-control fabric separator

PendingCN110409094AAvoid lostProtection securityDouble pile fabrics splittingFlywheelDigital control

The invention discloses a cutter belt adjustment system of a vertical-cutter-type high-speed digital-control fabric separator. The system comprises a flywheel box supporting plate, a left wallboard, aflywheel supporting plate, a right wallboard, a cutter belt, flywheels, an upward adjustment mechanism, two servo motors, a left supporting slide block, a cutter rack plate, a servo motor connectionrod, a first downward adjustment mechanism, four worm connection rods, a transmission mechanism, second, third, fourth and fifth downward adjustment mechanisms and a right supporting slide block; an output shaft of the first servo motor is connected with the upward adjustment mechanism and drives the upward adjustment mechanism to move up and down; an output shaft of the second servo motor is connected with the first downward adjustment mechanism through the servo motor connection rod; all the downward adjustment mechanisms are arranged at the upper side of the cutter belt and can drive the cutter belt to move downward. The cutter belt adjustment system is simple in structure, the position of the cutter belt is more conveniently, efficiently and accurately adjusted, and a spacer fabric ismore efficiently and stably separated. The aim of up-down adjustment for the cutter belt is to make a separated wool fabric flatter, and the separation process is more stable.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com