A single-sided machine with precise synchronous carriage device

A precise synchronization and single-sided machine technology, applied in the direction of machining/deformation, can solve the problems of low precision of synchronous traveling, wrong detection results, production line shutdown, etc., and achieve the effect of low cost, high precision and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

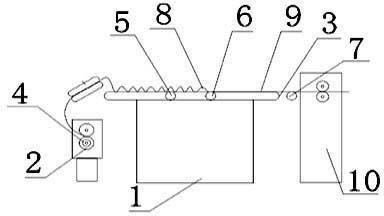

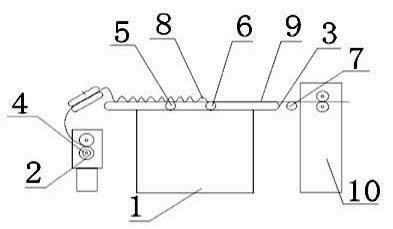

[0007] Such as figure 1 Shown, the present invention comprises frame 1, paper delivery roller 2, slow-feeding belt 3, and slow-feeding belt 3 is installed on the frame 1, and it also has encoder 4, low-speed tachometer wheel 5, high-speed tachometer wheel 6 and length generation 7, the tachometer wheel of encoder 4 is installed on the roll shaft of paper feed roller 2 of single-sided machine, low-speed tachometer wheel 5 and high-speed tachometer wheel 6 are respectively installed on the frame 1 through mounting support, and the low-speed tachometer wheel 5 The axle of the wheel shaft and the high-speed speed measuring wheel 6 is located under the slow-feeding belt 4. In normal working conditions, the cardboard crepe head 8 always swings back and forth behind the high-speed speed measuring wheel 6, and the low-speed speed measuring wheel 5 is always located at the cardboard crepe section. 7 is installed on the frame 1 and is positioned at the front end of the slow delivery bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com