Cutter belt adjustment system of vertical-cutter-type high-speed digital-control fabric separator

A technology of adjusting system and dividing machine, which is applied in the direction of double-sided pile fabric cutting and other directions, can solve the problems of not adopting numerical control intelligent control knife belt to move up and down, large volume of spacer fabric baffles, loss of material and financial resources, etc. Simple, loss prevention, raw material reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

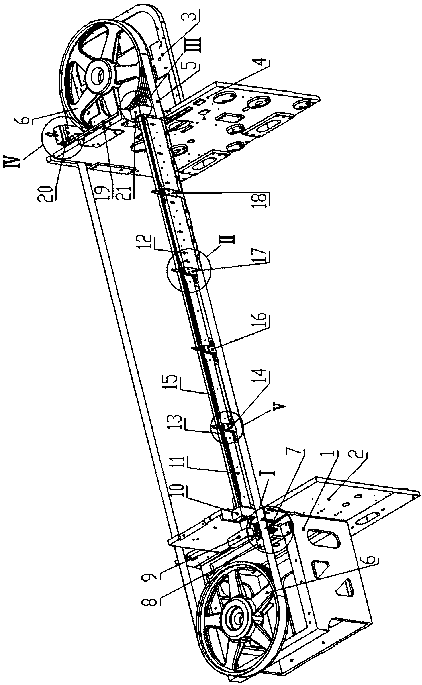

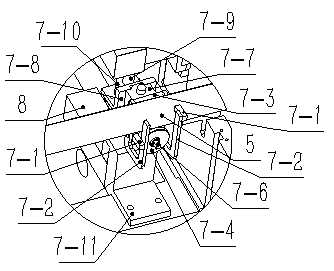

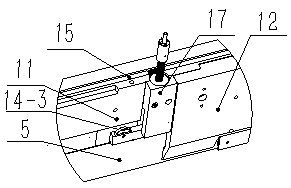

[0073] In order to illustrate the technical scheme and technical purpose of the present invention, below in conjunction with appendix Figure 1-20 The present invention is described in detail with specific embodiments.

[0074] A knife belt adjustment system of a vertical knife type high-speed numerical control fabric dividing machine, comprising a flywheel box support plate 1, a left wall plate 2, a flywheel support plate 3, a right wall plate 4, a vertical knife belt 5, and a flywheel 6;

[0075] The left wall panel 2 and the right wall panel 4 are parallel to each other, and they are vertically arranged on both sides of the knife belt 5. The flywheel box support plate 1 is fixed on the left wall panel 2, and the flywheel support plate 3 is fixed on the right wall panel 4. The supporting plate 1 and the flywheel supporting plate 3 are respectively provided with a vertical flywheel 6 in the axial direction, and the knife belt 5 is tensioned and arranged on the two flywheels 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com