Vertical material-distributing device and material-distributing method

A distributing device and technology of distributing materials, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of powder rolling, long waiting time for equipment, low distributing efficiency, etc., and achieve reasonable structure, avoid uncontrollable distributing effect, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

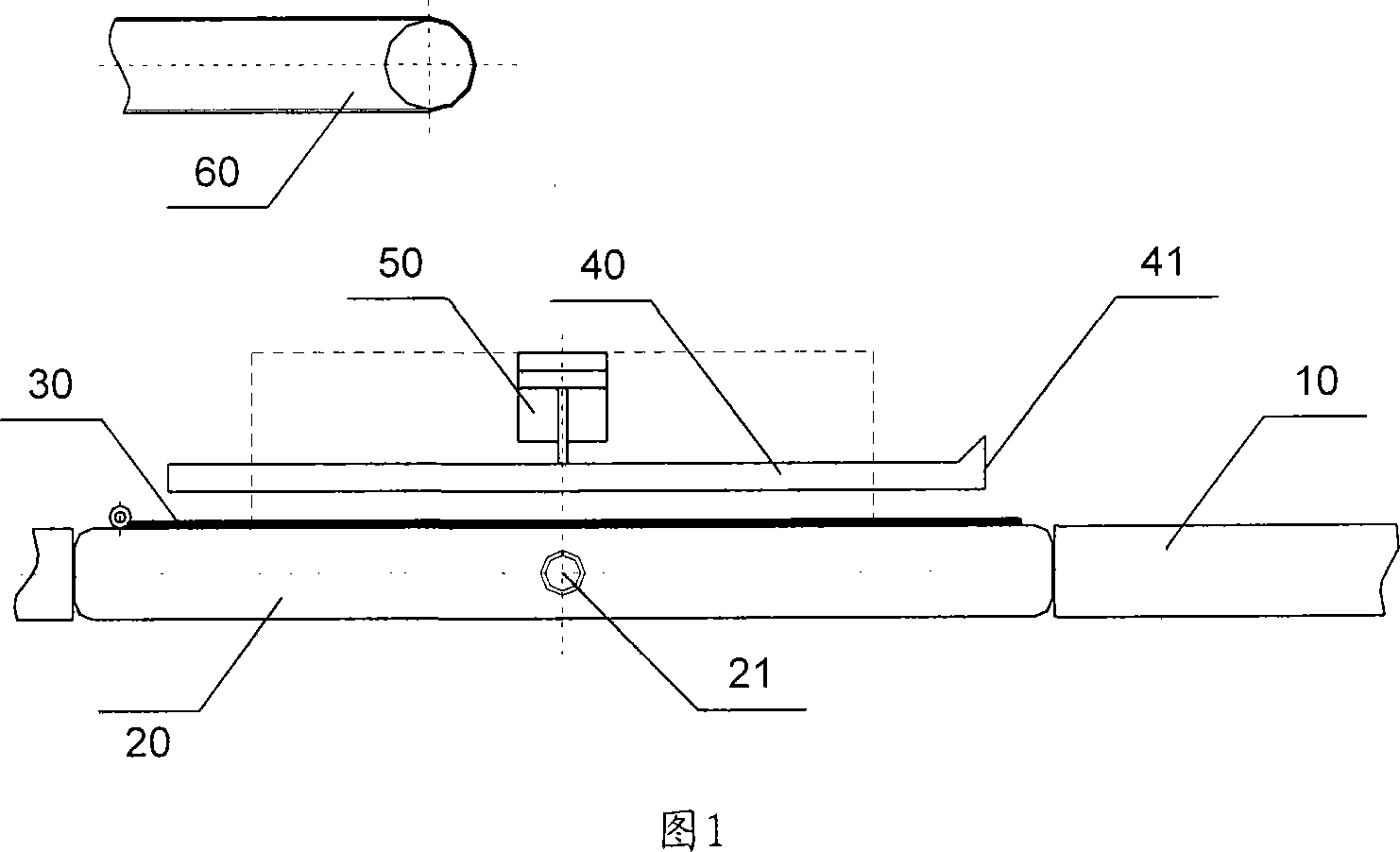

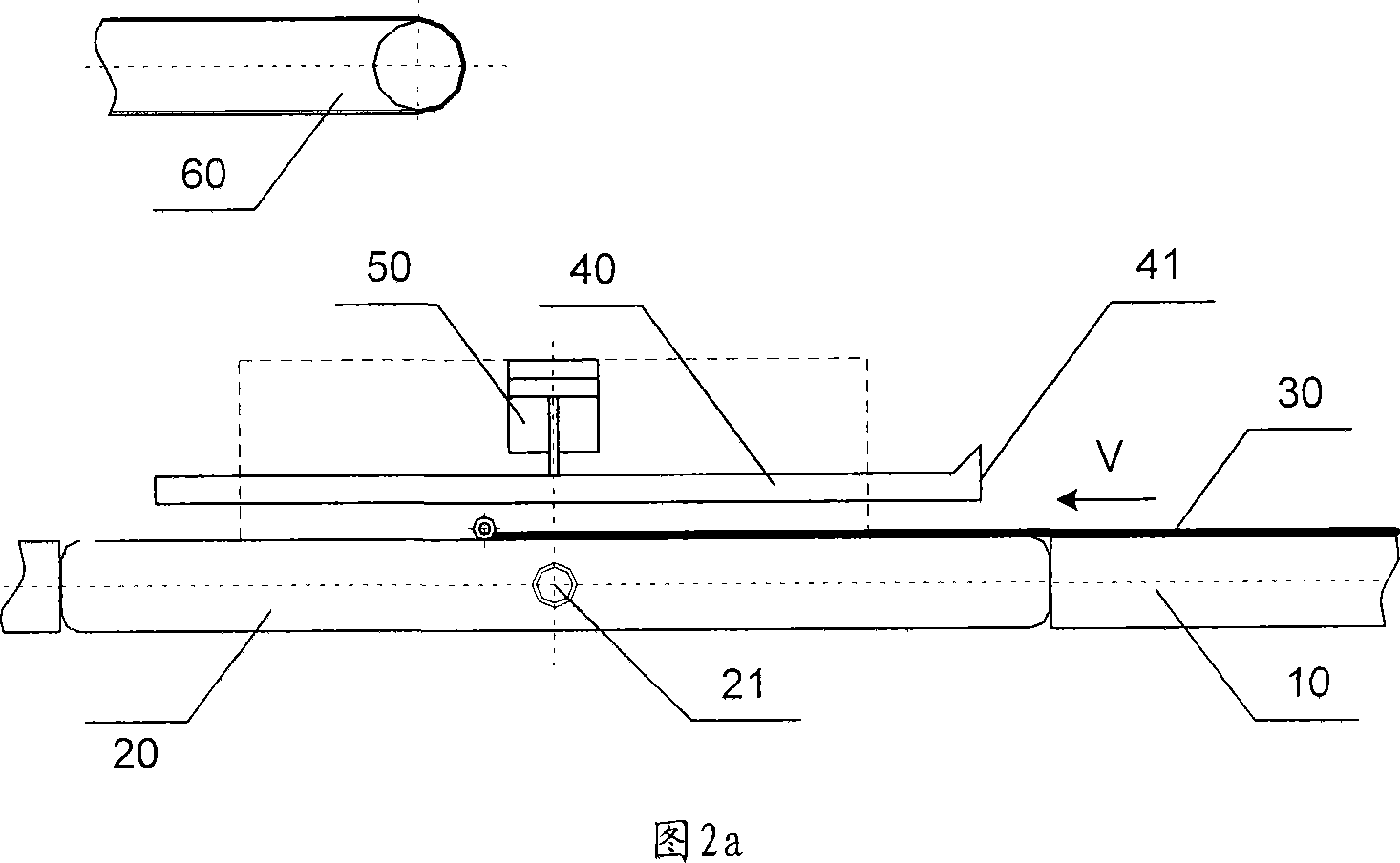

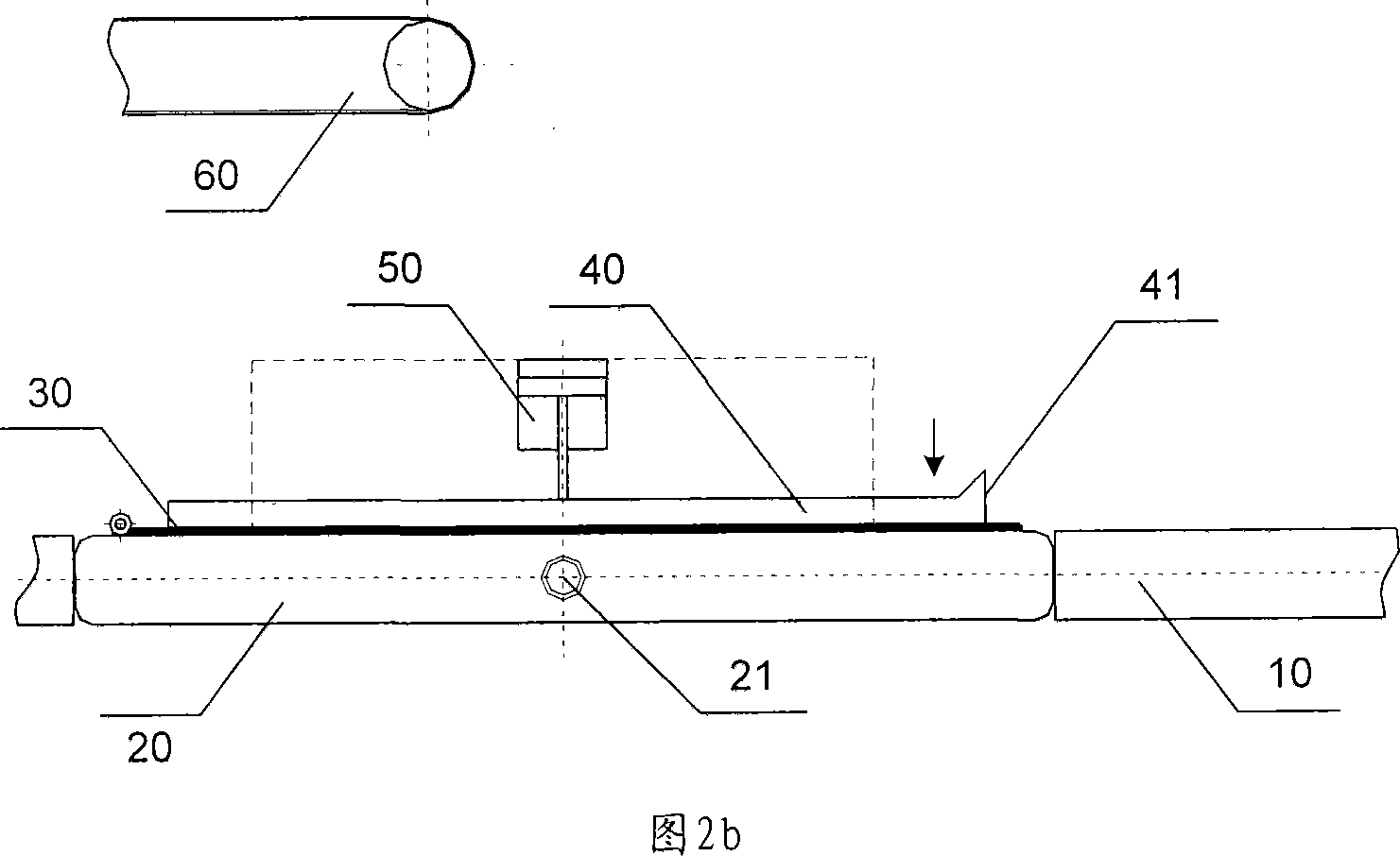

[0073] Fig. 1 is a schematic structural view of the vertical distribution device of the present invention. As shown in Figure 1, the main structure of the vertical distribution device includes an overturning platform 20 at the same level as the conveying platform 10, a powder carrier 30 responsible for conveying powder, a material box 40 and a filling device 60 located above the overturning platform 20, and turning over The platform 20 can be turned over by 90°, turned from a horizontal state to a vertical state, and returned to a horizontal state through a reverse 90° turn; the powder bearing carrier 30 can move on the conveying platform 10 and stop on the turning platform 20 in a horizontal state , start moving again after loading the powder, and send the powder into the press for pressing and molding; the liftable material box 40 is located above the turning platform 20, and when the material box 40 descends, the material box 40 is tightly buckled on the powder bearing On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com