Reciprocating multi-row grate type domestic refuse incinerator

A domestic waste incineration, multi-column technology, applied in the field of domestic waste incineration equipment, can solve the problems of poor operability, large size, and inability to adjust the drive mechanism of the grate separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

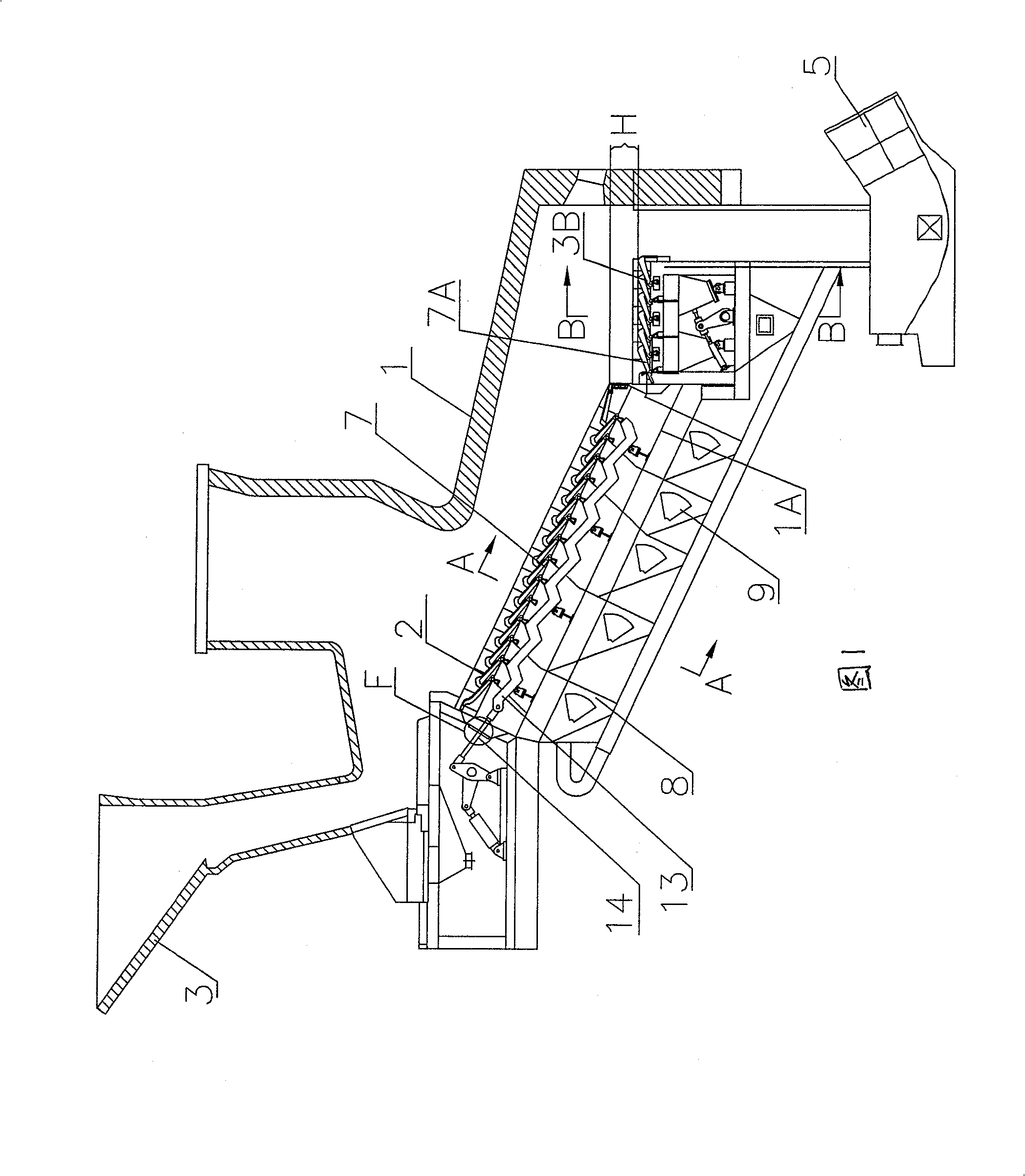

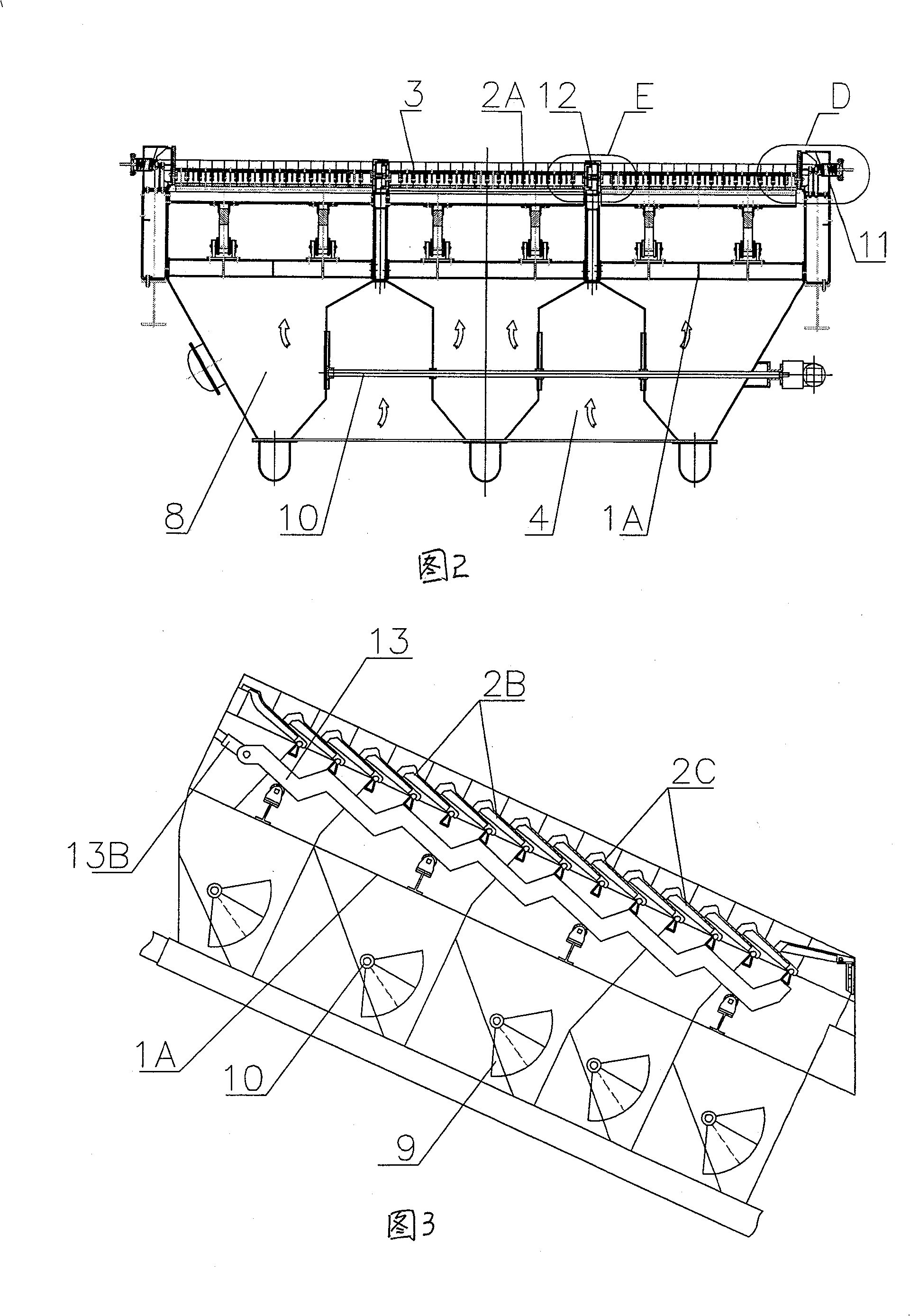

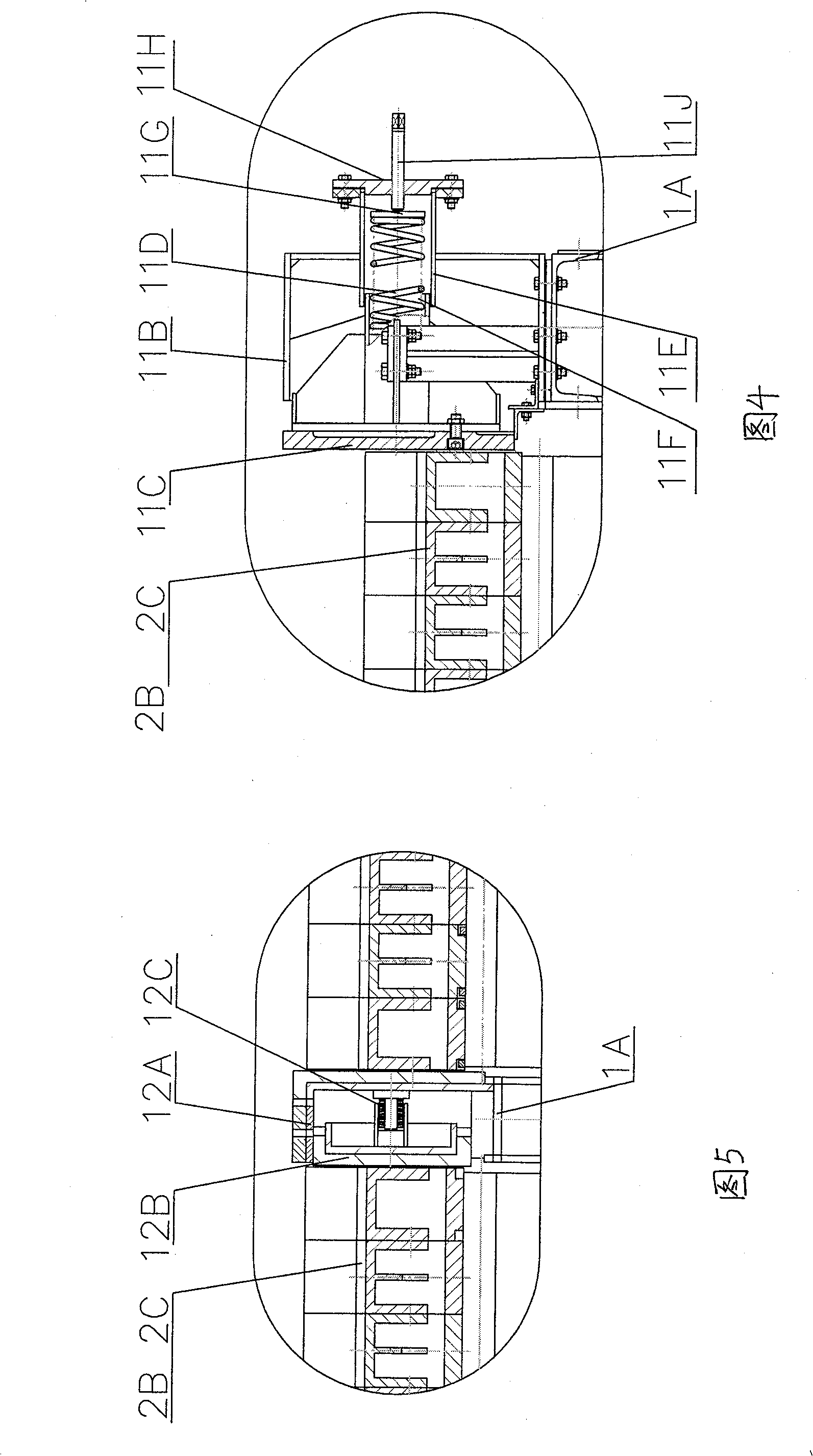

[0018] Such as figure 1 , figure 2 As shown, the reciprocating multi-row grate household waste incinerator of the present invention comprises a furnace body 1, a grate support 1A is arranged on the furnace body 1, a fire grate 2 is arranged on the grate support 1A, and the first and last ends of the furnace body 1 are respectively A hopper 3 and a slag extractor 5 are provided, and an air chamber 4 is arranged under the grate 2. The grate 2 includes a fixed grate piece 2B fixed on the grate bracket 1A and a movable grate piece 2C, and the movable grate piece 2C is arranged at intervals before and after Between two adjacent fixed grate pieces 2B and connected with the movable bracket 13, there are at least three rows of grate 2 arranged on the grate bracket 1A, and each row of grate 2 includes a fixed grate piece 2B, a movable grate piece 2C and a movable grate piece 2C The drive mechanism of the middle fire grate 2 in the fire grate 2 is equipped with an intermediate sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com