Automatic and semi-automatic cooking system and cooking method

A semi-automatic and automatic technology, used in cooking utensils, household utensils, applications, etc., can solve problems such as inability to correctly implement cooking processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

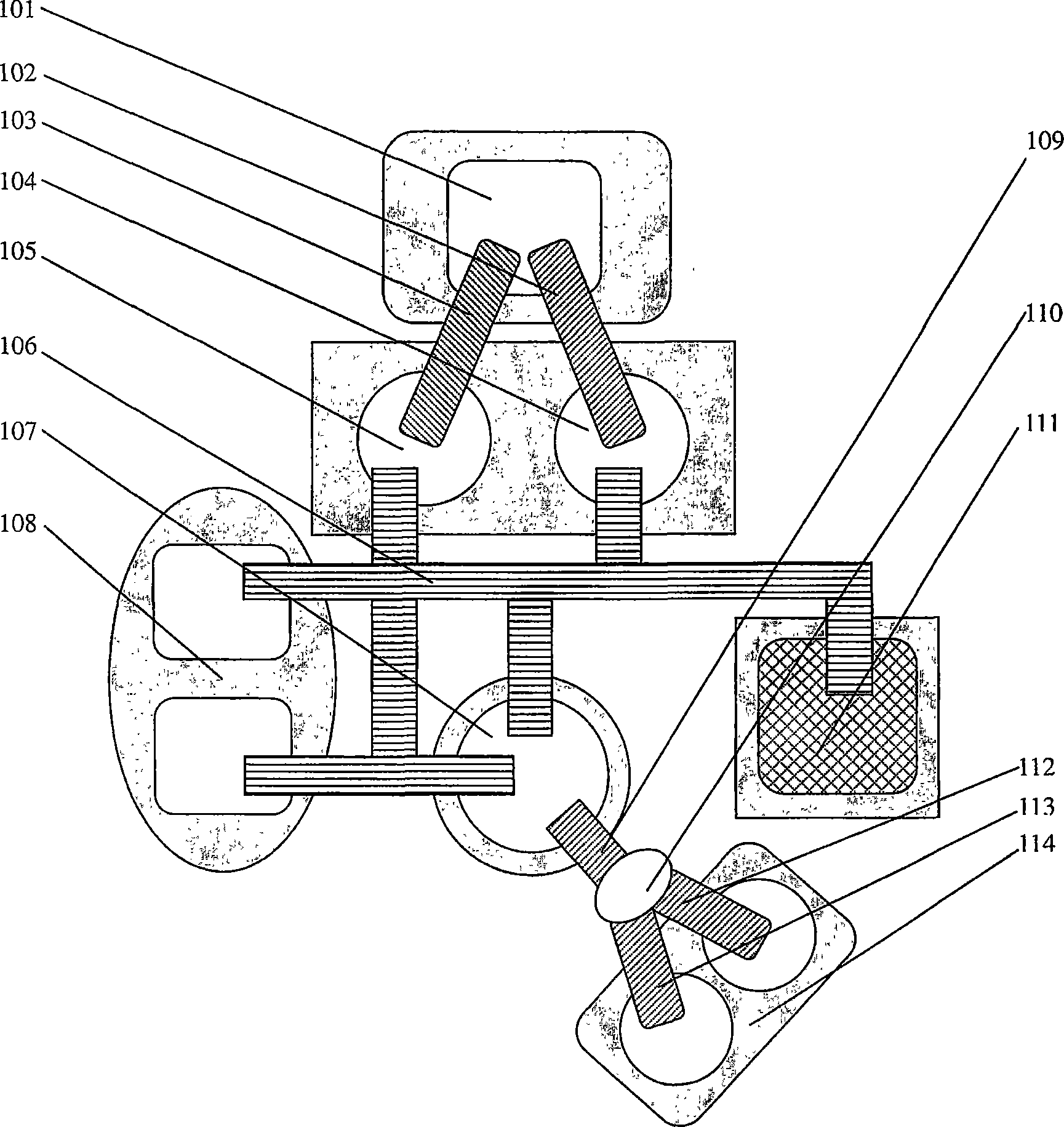

[0092] Please refer to figure 1 , which is a schematic plan layout of a cooking system implementing the present invention. The cooking system consists of double-pot frying sub-systems 104 and 105, lubricating oil machine 101, double-pot frying sub-system 108, cooker 107, steam cabinet 111, double-pot frying sub-system 114, two subsystems of lubricating oil and frying The material delivery device 102 and 103 between, the material delivery device 106 between the fried-boil-steam-fry subsystem, the material delivery device 109, 112 and 113 between the fry-boil two subsystems, and the material The storage container 110 and the like are composed.

[0093] The following takes cooking techniques such as "smooth frying", "burning" and "simmering" as examples to illustrate the operation of the cooking system:

[0094] Stir-frying: the main ingredients are put into the lubricating oil machine 101 by the feeding device, and are scattered by the sliding device on the machine. and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com