Dual main machine crushing production line and method based on frequency conversion control technology

A technology of frequency conversion control and crushing methods, which is applied in the direction of sequence/logic controller program control, electrical program control, chemical instruments and methods, etc. Level broken and other issues, to achieve the effect of simple structure, easy adjustment, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

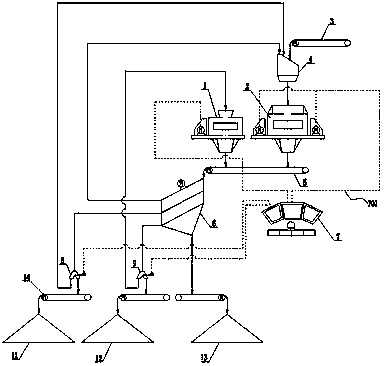

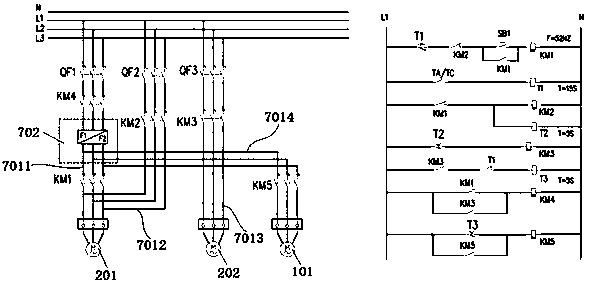

[0028] Such as figure 1 As shown, a dual-main crushing production line based on frequency conversion control technology includes a shaping machine 2 and a sand making machine 1. The feeding port of the shaping machine 2 is connected to a buffer bin 4, and a feeding device is provided above the buffer bin 4. 3. The discharge port of the shaping machine 2 and the sand making machine 1 is connected to the feed port of the vibrating screening mechanism through the running belt 5. The vibrating screening mechanism includes a vibrating screen 6 and a material divider. The vibrating screen 6 The sieve screen is multi-layered, specifically more than three layers. From top to bottom, it is an overdiameter material layer, a finished crushed stone layer, a finished rice st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com