Steel pipe machining system

A processing system and steel pipe technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of low efficiency, increased time cost and labor cost, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

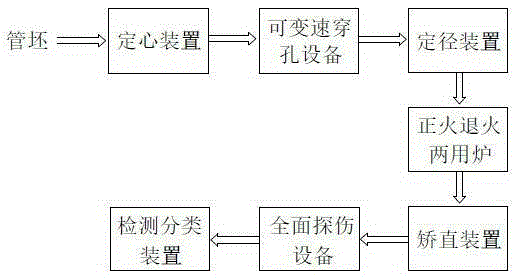

[0036] like figure 1 As shown, the present invention includes a centering device, a variable-speed piercing device, a dual-purpose furnace for normalizing and annealing, a sizing device, a straightening device, a comprehensive flaw detection device, and a detection and classification device. The centering device, sizing device, and straightening device are existing equipment in most steel pipe production plants, and complete the necessary procedures in the steel pipe processing process, so they will not be repeated here.

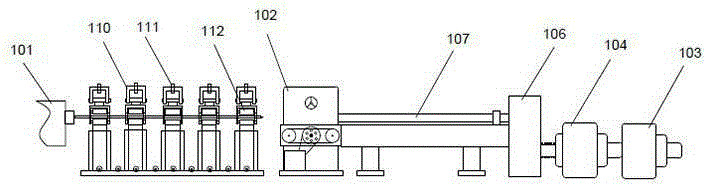

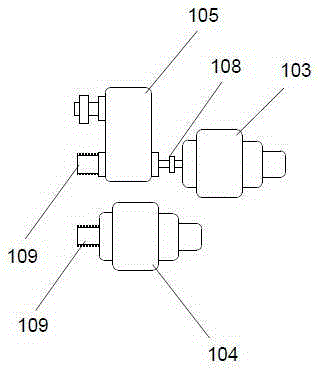

[0037] like figure 2 , 3 As shown, the variable-speed piercing equipment includes a piercing device 101, a clamping device, and a positioning drive device. The positioning driving device includes a positioning seat 102 and a variable speed driving device. The variable-speed driving device includes a high-speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com