Automatic armband stitch locking production device and stitch locking processing method thereof

A technology for producing devices and armbands, which is applied in the field of automatic armband seaming production devices, can solve problems such as poor product consistency and affecting work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

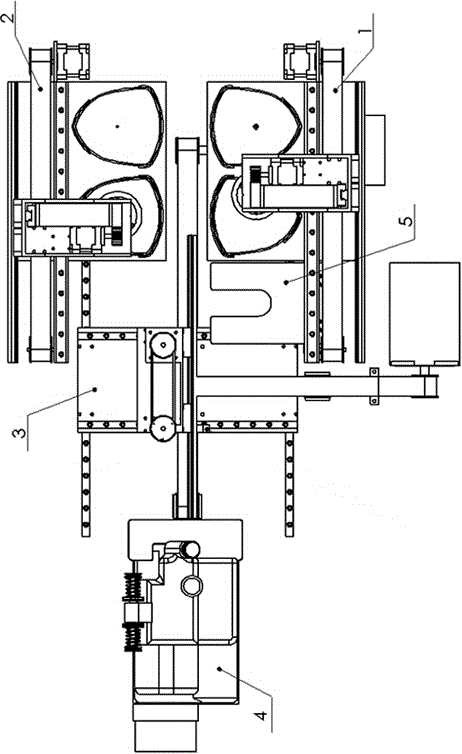

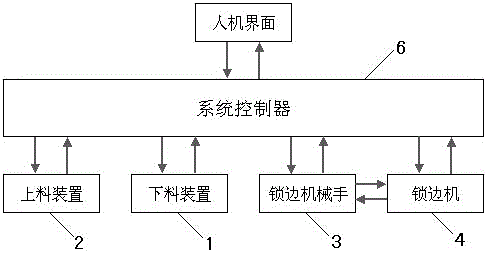

[0028] refer to figure 1 As shown, an automatic armband overlock production device includes a overlock manipulator 3, and one end of the running guide rail of the overlock manipulator 3 is provided with an overlock machine 4, and the other end is provided with a loading device 2 and an unloading device 1. The material device 2 and the unloading device 1 are respectively located on both sides of the running guide rail of the overlock manipulator 3, and a stripping device 5 is arranged on one side of the overlock manipulator 1, and the overlock manipulator 3, over overlock machine 4, upper The feeding device 2 and the unloading device 1 are controlled by a system controller 6 . System controller 6 includes PLC or other computer controllers.

[0029] refer to image 3 As shown, in such a complex automatic production line, each piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com