Vehicular continuous packaging garbage can

A technology for trash cans and garbage, applied in trash cans, garbage collection, vehicle parts, etc., can solve the problems of inability to realize convenient and continuous packaging operations, complex use, and high requirements for external conditions, so as to improve convenience, environmental protection, and convenience. Pick and place operation, eliminating the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

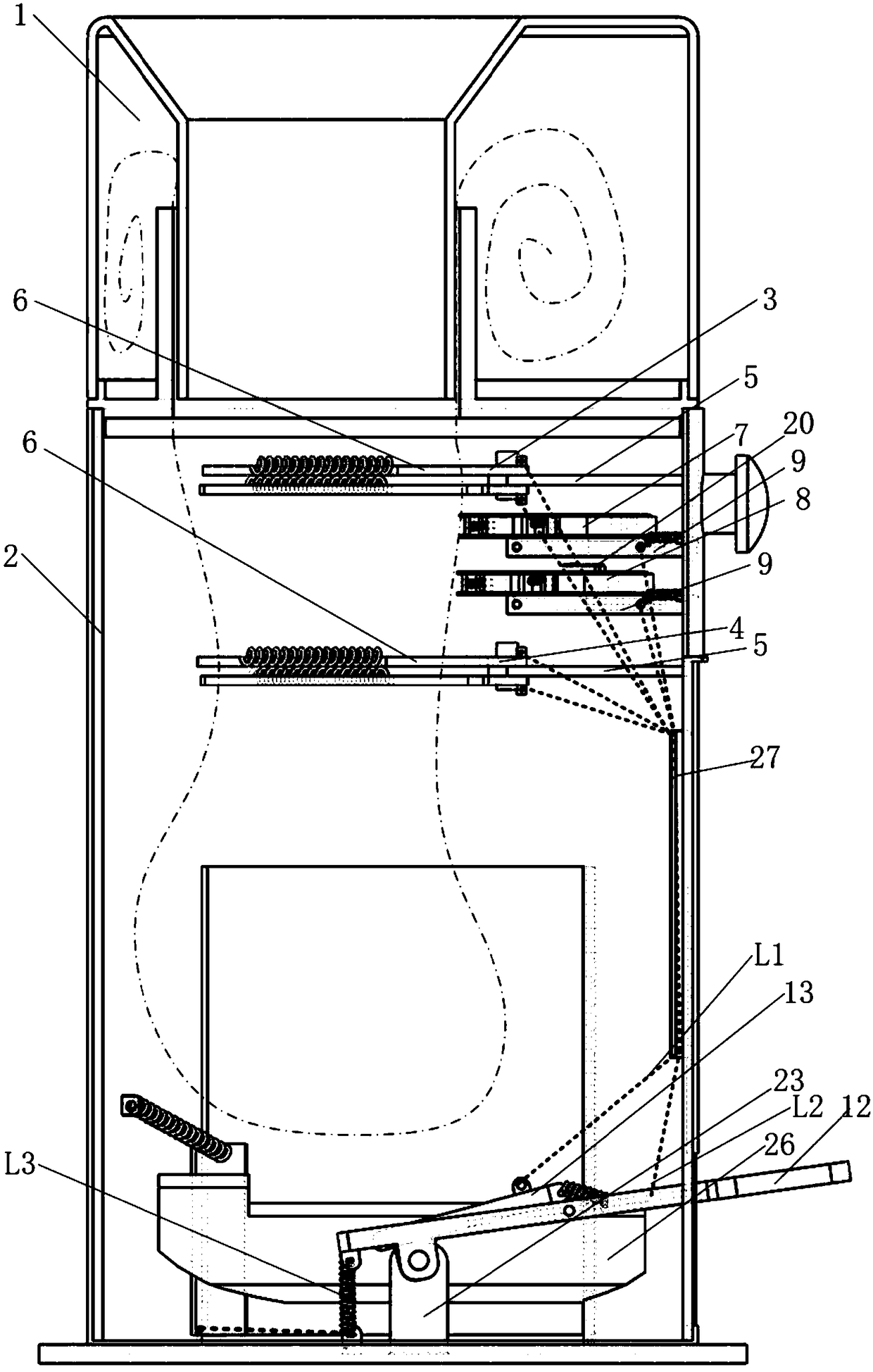

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

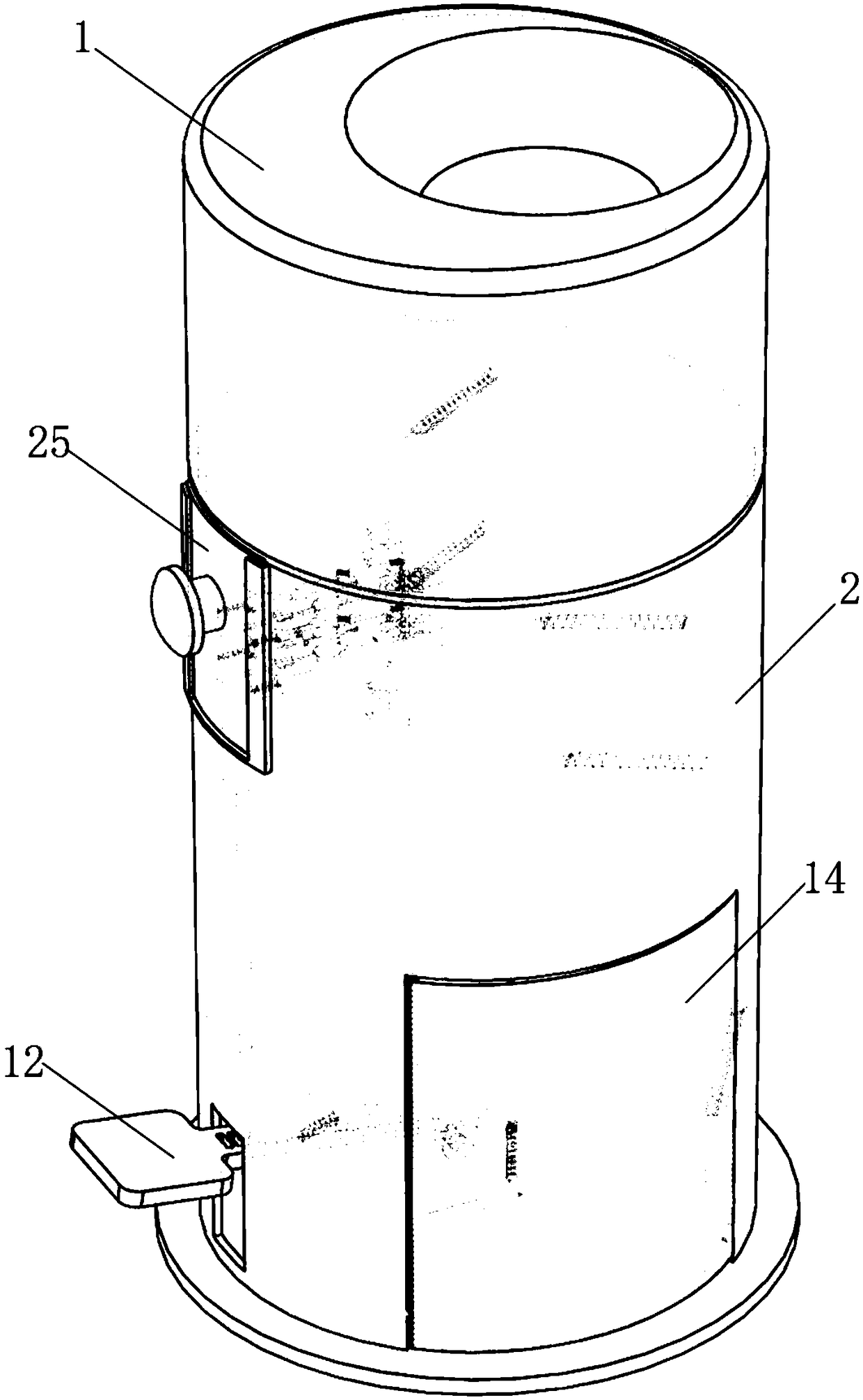

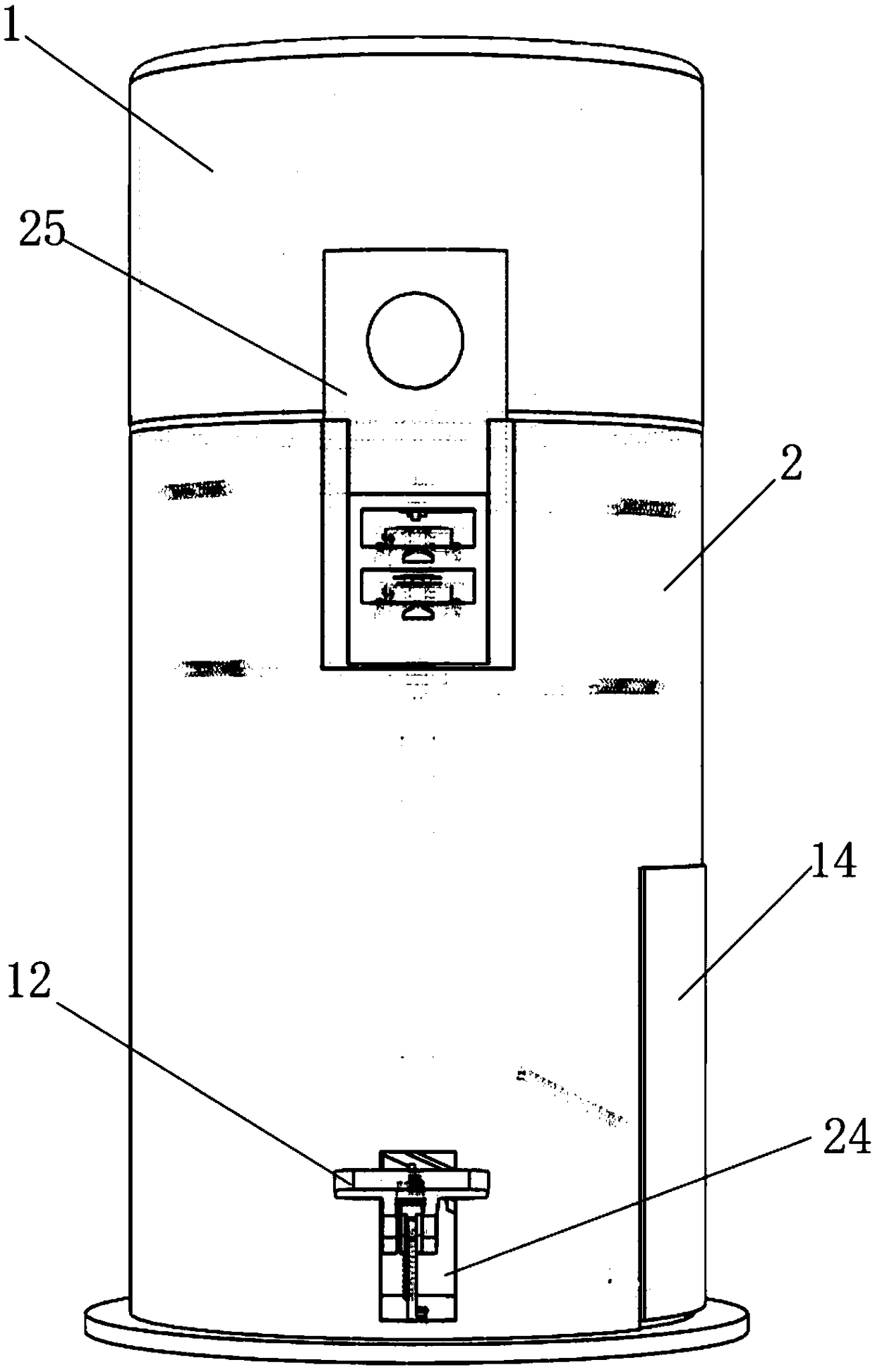

[0040] Such as figure 1 and 2 As shown, a vehicle-mounted continuous packaging trash can of the present invention is composed of a main cylinder 2 and an auxiliary cylinder 1, the auxiliary cylinder 1 is installed above the main cylinder 2, and the top opening of the auxiliary cylinder 1 is provided for putting in garbage; the main cylinder 2 There are three openings on the outer wall, among which a sliding door 25 is installed at the opening on the upper part of the main cylinder 2, which is convenient for taking and replacing the sealing tape; the lower part of the main cylinder 2 is provided with a pedal door 24 and a cylinder door 14, and the pedal door 24 is used for the outer pedal Stretch out the main cylinder 2; the cylinder door 14 is used to discharge the garbage bags that have been packaged.

[0041] In a preferred embodiment of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com