Mining underground drilling, anchoring and rock breaking integrated excavation type loader

A loader and anchor drilling technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of increased construction procedures, low efficiency of equipment operations, instability of roadway surrounding rock, etc. problems, to achieve the effect of increasing the contact area and bearing capacity, facilitating the reinforcement of surrounding rocks, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

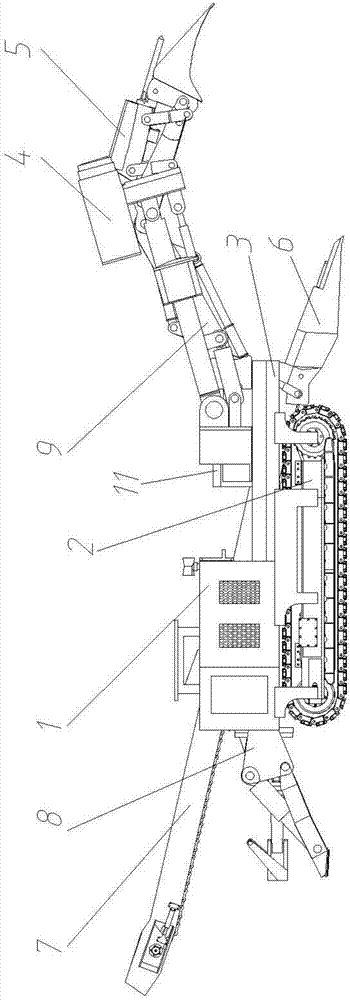

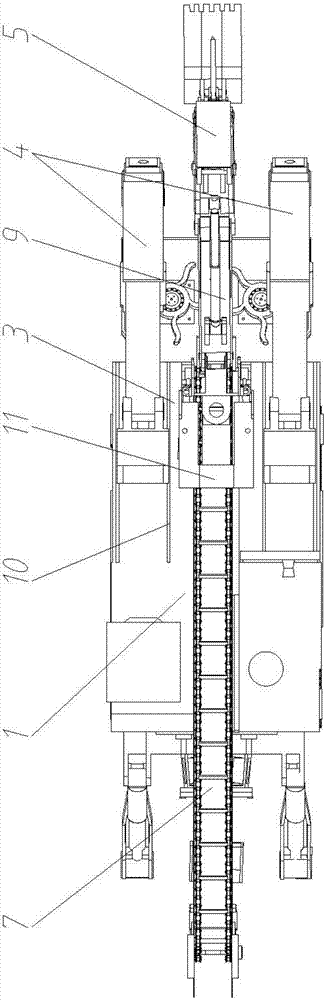

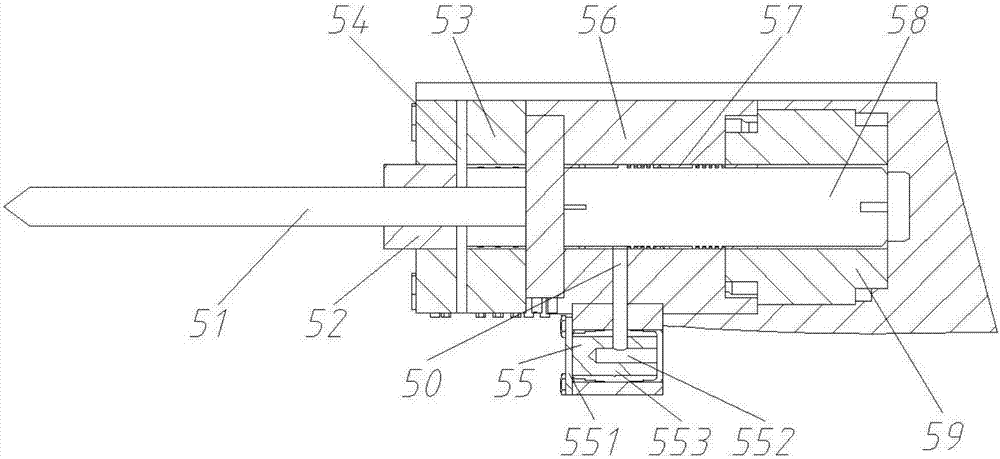

[0030] Referring to the accompanying drawings, it can be seen that the excavator loader integrated with drilling, bolting and rock breaking for underground mines is characterized in that it includes a walking part 2 that can walk underground, and is installed on the upper part of the rear end of the walking part 2 and can move together with the walking part 2. Body 1, a frame 3 that is installed on the upper part of the front end of the running part 2 and can move together with the running part 2, the rear end of the frame 3 is connected with the front end of the body 1, and the middle part of the body 1 and the middle part of the frame 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com