Soil conditioner prepared from sludge and preparation method thereof

A technology of soil improver and silt, which is applied in the direction of soil conditioning materials, chemical instruments and methods, and other chemical processes, can solve the problems of affecting the normal growth of plants, difficulty in engineering application, high alkalinity of planting soil, etc., and achieve economical and Double environmental benefits, saving landfill cost and overall cost, rich nutrition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

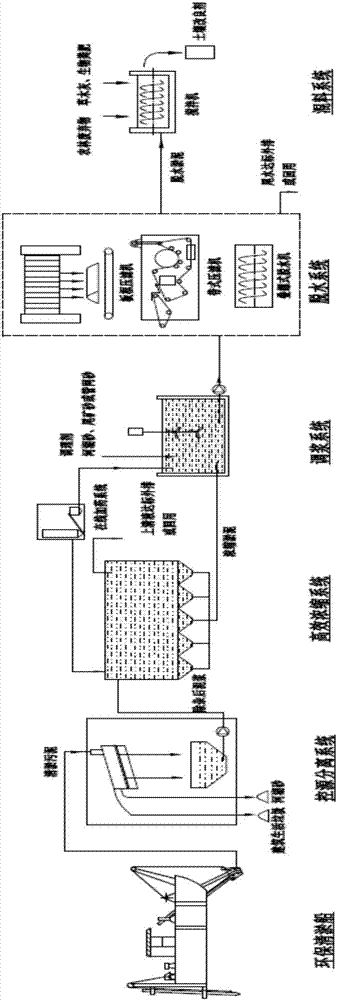

Method used

Image

Examples

Embodiment 1

[0035] A dredging project in Hunan was selected. The water content of river and lake sediments was 75wt%, the organic matter content was 4.01wt%, and the total nutrients (N+P 2 o 5 +K 2O) content 1.20wt%. The water content of the dredged sludge is 95wt%, and the source control separation system is used to remove impurities to obtain construction domestic waste, river and lake sand, and sludge after impurities removal. After removal of impurities, the sludge is dehydrated to water content by a high-efficiency concentration system rate of 87wt%, then mix with lime and tailings sand in the mixing system (the addition of lime is 8% of the quality of river and lake bottom mud, the addition of tailings sand is 10% of the quality of river and lake bottom mud, and the particle size of tailings sand is 0.25~0.35mm), and then pumped into the belt filter press dehydration system, the dehydration rate is further reduced to 55wt%. Transport the dewatered sludge to the mixing system, add...

Embodiment 2

[0038] The water content of river and lake bottom mud in a dredging project in Changzhou is 78wt%, organic matter content is 8wt%, and total nutrients (N+P 2 o 5 +K 2 O) content 8.36wt%. The water content of the dredged sludge is 92wt%, and the source control separation system is used to remove impurities to obtain construction domestic waste, river and lake sand, and sludge after impurities removal. After removal of impurities, the sludge is dehydrated to water content by a high-efficiency concentration system rate of 82wt%, and then mixed with alkali slag and river and lake sand in the slurry mixing system (the addition of alkali slag is 6% of the quality of river and lake bottom mud, and the addition of river and lake sand is 10% of the quality of river and lake bottom mud, and the addition of river and lake sand is 10% of the quality of river and lake bottom mud. The particle size of the sand is 0.25-0.35mm), and then pumped into the dehydration system of the plate and f...

Embodiment 3

[0041] A dredging project in Huangshi was selected. The water content of river and lake sediments was 70wt%, organic matter content was 8wt%, and the total nutrients (N+P 2 o 5 +K 2 O) content 8.36wt%. The water content of the dredged silt is 93wt%, and the source control separation system is used to remove impurities to obtain construction domestic waste, river and lake sand and silt after removal of impurities. After removal of impurities, the silt is dehydrated to water content by a high-efficiency concentration system rate of 82wt%, and then mixed with phosphogypsum and tailings sand in the slurry mixing system (the addition of phosphogypsum is 5% of the quality of river and lake bottom mud, the addition of tailings sand is 5% of the quality of river and lake bottom mud, the particle size of tailings sand diameter is 0.25-0.35mm), and then pumped into the stacked screw dehydration system, the dehydration rate is further reduced to 57wt%. Transport the dewatered sludge t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com