Textile dyeing sludge processing method for removing heavy metal and dehydrating

A technology for printing and dyeing sludge and heavy metals, applied in dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as heat and radiation, polluted waste gas, high cost, etc., to achieve The effect of less one-time investment, saving investment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

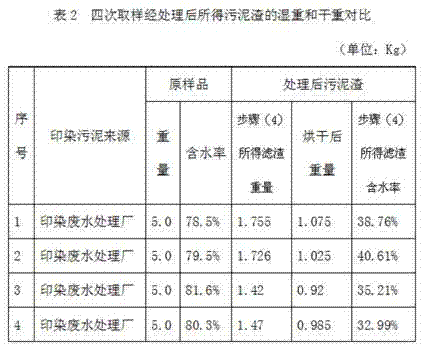

[0025] The printing and dyeing sludge sample was taken from the wastewater treatment plant of a printing and dyeing enterprise in Lanxi, Zhejiang. The moisture content was 78.5% and the solid content was 21.5%. The treatment method includes the following steps:

[0026] (1) Pretreatment of printing and dyeing sludge: Put 5.0 Kg of printing and dyeing sludge into a beaker, then add 0.1L of industrial grade sulfuric acid to the beaker and stir for 30 minutes to form a solid-liquid mixture;

[0027] (2) Microwave heating: send the solid-liquid mixture obtained in step (1) into a microwave device to raise the temperature to 90°C and keep it for 60 minutes;

[0028] (3) Filtration: filter the solid-liquid mixture treated in step (2), and perform solid-liquid separation to obtain sludge residue and filtrate;

[0029] (4) Precipitating heavy metals: adjust the pH of the filtrate obtained in step (3) to 7.0 with sodium hydroxide solution, then add 20g of industrial grade sodium sulfide, stir f...

Embodiment 2

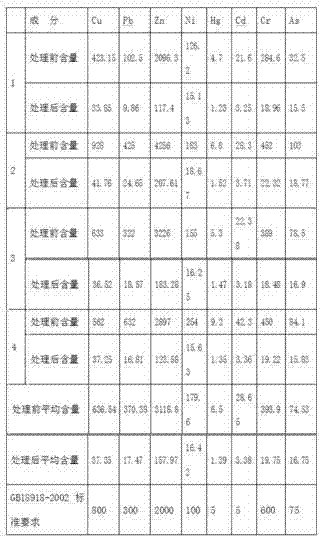

[0041] The printing and dyeing sludge sample was taken from the wastewater treatment plant of a printing and dyeing enterprise in Zhongshan, Guangdong, with a moisture content of 82.4% and a solid content of 17.6%. Three consecutive experimental treatments were carried out, and 2.0Kg of printing and dyeing sludge was taken in each experiment. The treatment steps are the same as in Example 1, the specific process parameters of each step are shown in Table 4, the wet weight and dry weight of the sludge obtained after treatment are shown in Table 5, and the heavy metal content before and after the printing and dyeing sludge treatment is shown in Table 6.

[0042]

[0043]

[0044] Table 6 Comparison of the average content of heavy metals before and after treatment obtained in three consecutive experiments

[0045] (Unit: mg / Kg)

[0046] ingredientCu Pb Zn Ni Hg CdCr As Average content before treatment819.57462.82512215.34.8518.21485.258.6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com