Mud brick fired by environment-friendly comprehensive utilization of wastes and preparation method thereof

A waste and sludge technology, which is applied in the field of environmental protection utilization of waste resources, can solve the problems that the characteristics of sludge and sludge have not been fully utilized, heavy metals in sludge have not been effectively resolved, and river sludge and domestic sludge are mixed up to achieve social and economic benefits. Significant, landfill-saving, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

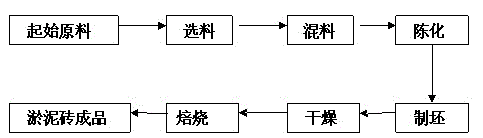

Method used

Image

Examples

Embodiment 1

[0035]Step 1, material selection: select the dredged silt from the Baima Lake dredged silt yard that has been preliminarily dehydrated with a moisture content of ≤80% and a clay component content of ≥30%, and select Changshu Jiangnan Water Sewage Treatment Plant with a clay component content of ≥30% for water treatment The sludge generated after the waste incineration plant in Changshu is selected from the bottom slag of domestic waste incineration and the active waste produced after domestic waste incineration that meet the standard of "Slag Aggregate for Domestic Waste Incineration" (GB / T 25032-2010). fly ash, choose common II grade quicklime, and all selected materials meet the component weight ratio of the present invention;

[0036] Step 2, mixing materials: according to the weight ratio of 50% dredged silt, 10% sludge, 20% domestic waste incineration bottom slag, 17.5% fly ash and 2.5% quicklime, weigh 12.2 kg of selected materials, using Zhengzhou The JZC500 drum mixer ...

Embodiment 2

[0042] Step 1, material selection: Select Ningbo Sanjiang River Silt with water content ≤ 80% and clay component content ≥ 30% after preliminary dehydration, select sludge from sewage treatment plant with clay content ≥ 30%, and select waste incineration from Everbright Suzhou The domestic waste incineration bottom slag and fly ash with active waste produced after domestic waste incineration that meet the standard of "Household Waste Incineration Slag Aggregate" (GB / T 25032-2010) in power plants shall be ordinary II quicklime, all Material selection conforms to the component weight ratio of the present invention;

[0043] Step 2, mixing materials: 16.2 kg of selected materials are weighed according to the weight ratio of dredged silt 35%, sludge 15%, domestic waste incineration bottom slag 25%, fly ash 20% and quicklime 5%. The JZC500 drum mixer produced by Innovative Construction Machinery Manufacturing Co., Ltd. adopts the mechanical automatic feeding method. Put it into t...

Embodiment 3

[0049] Step 1, material selection: Select the Qiantang River dredging sludge with a moisture content ≤ 80% and a clay content ≥ 30% after preliminary dehydration, select sewage treatment plant sludge with a clay content ≥ 30%, and select waste from Shanghai Pufa Yuqiao The domestic waste incineration bottom slag and fly ash with active waste produced after domestic waste incineration that meet the standard of "Household Waste Incineration Slag Aggregate" (GB / T 25032-2010) in the incineration power plant shall be ordinary II quicklime, all Material selection conforms to the component weight ratio of the present invention;

[0050] Step 2, mixing materials: 12.2 kg of selected materials were weighed according to the weight ratio of dredged silt 65%, sludge 5%, domestic waste incineration bottom slag 20%, fly ash 7.5% and quicklime 2.5%, using Zhengzhou The JZC500 drum mixer produced by Innovative Construction Machinery Manufacturing Co., Ltd. adopts the mechanical automatic fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com