Automatic inner bore grinding device and automatic inner bore grinding method

An automatic device and inner hole technology, which is used in grinding machines, grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of high inner hole processing efficiency, low degree of automation, and low labor intensity of staff and other problems, to achieve the effect of improving inner hole processing efficiency, low labor intensity and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

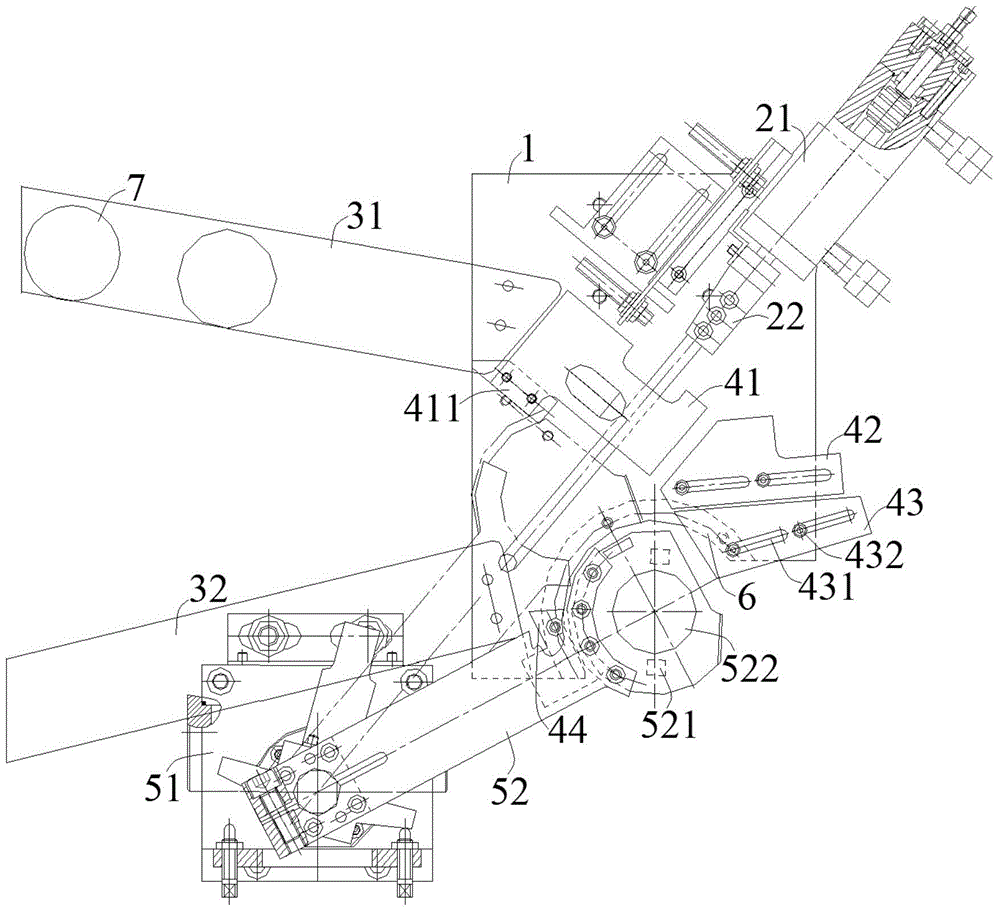

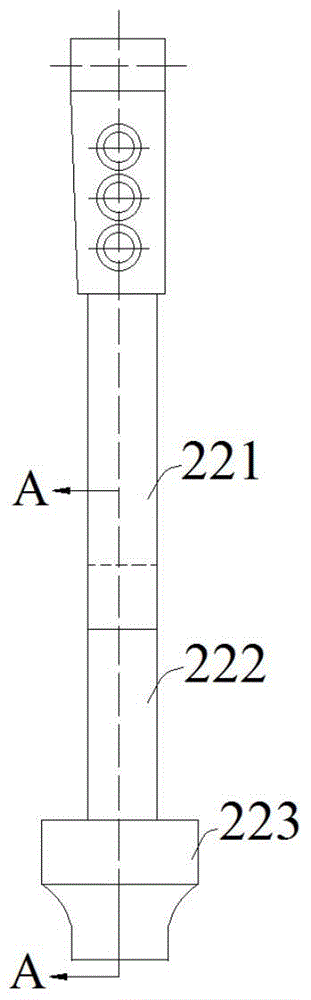

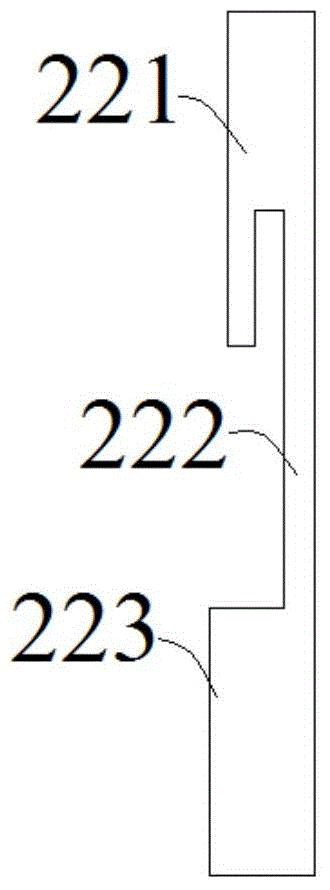

[0034] see figure 1 , an automatic device for inner hole grinding in this embodiment, including a feeding channel 31 , a material saving mechanism, a pushing mechanism, a material blocking mechanism and a feeding channel 32 . Wherein: the material-saving mechanism includes a material-saving oil cylinder 21 and a material-saving rod 22 , the material-saving oil cylinder 21 is installed on the aluminum plate 1 , and the piston of the material-saving oil cylinder 21 is connected to the material-saving rod 22 . The material blocking mechanism is also installed on the aluminum plate 1 , and the material blocking mechanism includes a material saving groove 41 , a first material blocking plate 42 , a second material blocking plate 43 and a third material blocking plate 44 . The input port of the material saving chute 41 corresponds to the output port of the feeding channel 31 , and a first material blocking plate 42 is arranged at the output port of the material saving chute 41 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com